## Page unknown

UNIROYAL CHEM-TEXTS

Vol. 14, 1980 PUBLISHED FOR THE PEOPLE OF UNIROYAL CHEMICAL NO. 1

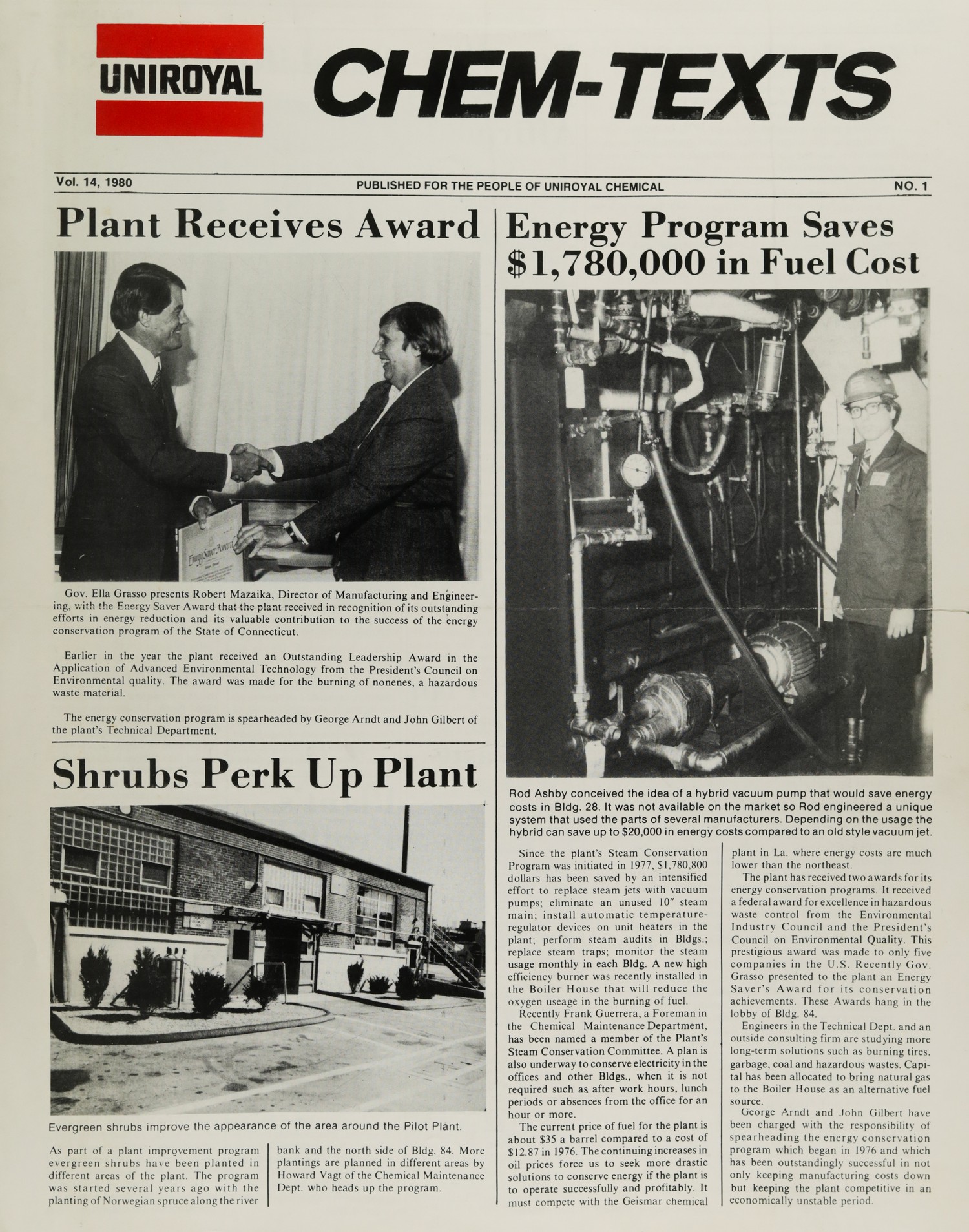

Plant Receives Award

Gov. Ella Grasso presents Robert Mazaika, Director of Manufacturing and Engineering with the Energy Saver Award that the plant received in recognition of its outstanding efforts in energy reduction and its valuable contribution to the success of the energy conservation program of the State of Connecticut.

Earlier in the year the plant received an Outstanding Leadership Award in the Application of Advanced Environmental Technology from the President’s Council on Environmental Quality. The award was made for the burning of monomers, a hazardous waste material.

Energy Program Saves $1,780,000 in Fuel Cost

The energy conservation program is spearheaded by George Arndt and John Gilbert of the plant’s Technical Department.

Rod Ashby conceived the idea of a hybrid vacuum pump that would save energy costs in Bldg. 28. It was not available on the market so Rod engineered a unique system that used the parts of several manufacturers. Depending on the usage the hybrid can save up to $20,000 in energy costs compared to an old-style vacuum jet.

Since the plant’s Steam Conservation Program was initiated in 1975, $1,780,000 dollars has been saved by an intensified program with vacuum pumps, eliminate an unused 10″ steam main; install automatic temperature-regulator devices on unit heaters in the plant; perform steam audits in Bldg. 4, replace steam traps, monitor the steam usage monthly in each Bldg. A new high efficiency Boiler House that will reduce the oxygen usage in the burning of fuel.

Recently Frank Guerrera, a Foreman in the Chemical Maintenance Department, has been named a member of the Plant’s Steam Conservation Committee. A plan is also underway to conserve electricity in the offices and some Bldgs., which it is not required such as after a normal work period, or absences from the office for an hour or more.

The current price of fuel for the plant is about $15 a barrel compared to a cost of $12.87 in 1979. The continuing increases in oil prices force us to seek more drastic solutions to conserve energy if the plant is to operate successfully and profitably. It must compete with the German chemical plant in La., where energy costs are much lower than the Northeast.

The plant has received top awards for its energy conserving programs. It received a federal award for excellence in hazardous waste control from the Environmental Industry Council and the President’s Council on Environmental Quality. This prestigious award was made to only five companies in the U.S. Recently, Gov. Grasso presented the plant with the Energy Saver’s Award for its conservation achievements. These Awards hang in the lobby of Bldg. 84 Engineers in the Technical Dept. and an outside consulting firm are studying more long-term solutions such as burning tires, garbage, coal and hazardous wastes. Capital has been allocated to bring natural gas to the Boiler House as an alternative fuel source.

George Arndt and John Gilbert have been charged with the responsibility of spearheading the energy conservation program which began in 1976 and which has been outstandingly successful in not only keeping manufacturing costs down but keeping the plant competitive in an economically unstable period.

Shrubs Perk Up Plant

As part of a plant improvement program, evergreen shrubs have been planted in different areas of the plant. The program was started several years ago with the planting of Norwegian spruce along the river bank and the north side of Bldg. 84. More plantings are planned in different areas by Howard Vigor of the Chemical Maintenance Dept. who heads up the program.

Evergreen shrubs improve the appearance of the area around the Pilot Plant.

—