## Page 001

UNIROYAL CHEM-TEXTS

Vol. 3, 1969 No. 10

PUBLISHED FOR THE PEOPLE OF UNIROYAL CHEMICAL

The Small Plant In A Big Plant

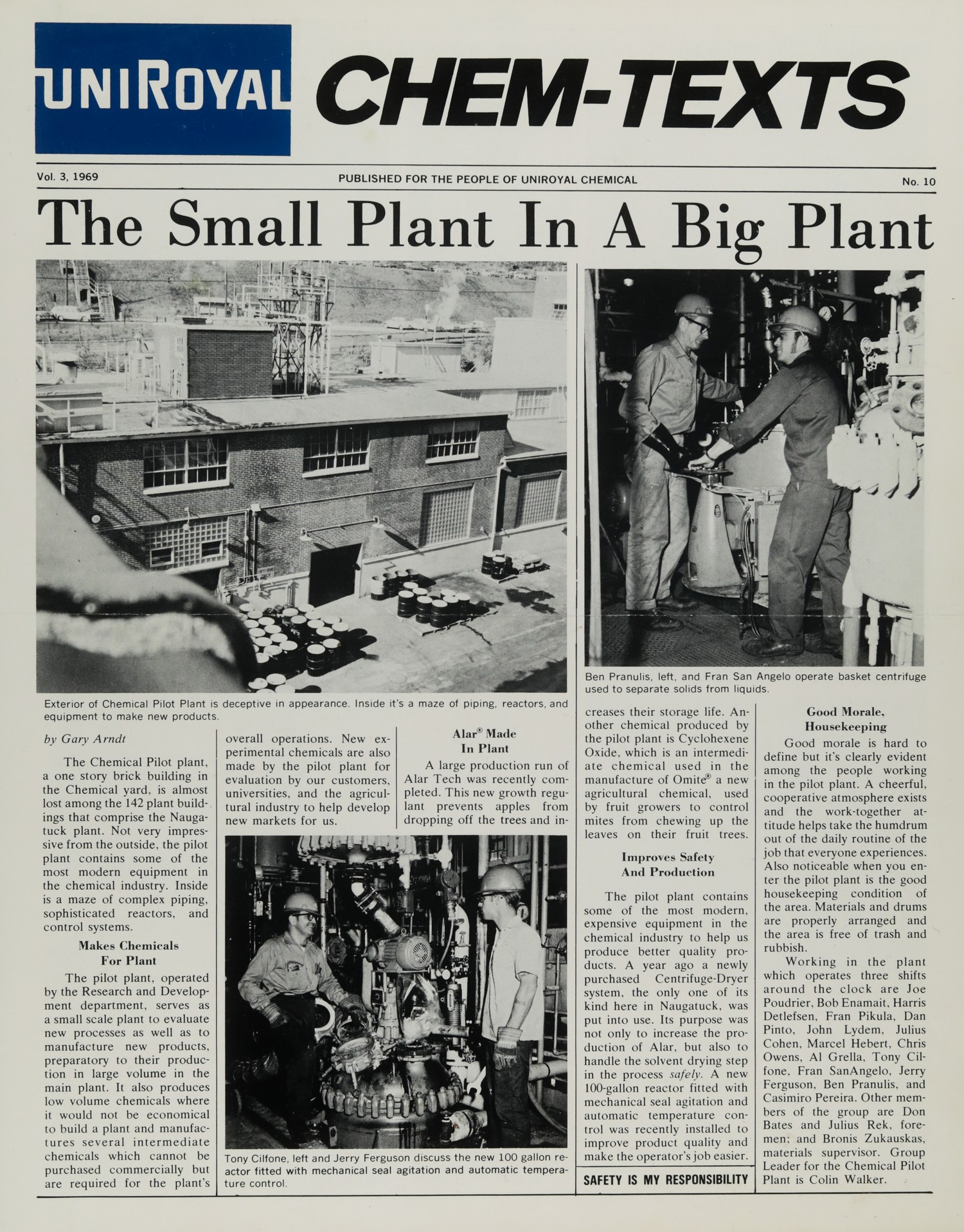

Exterior of Chemical Pilot Plant is deceptive in appearance. Inside it’s a maze of piping, reactors, and equipment to make new products.

The Chemical Pilot plant, a story brick building in the Chemical yard, is almost lost among the 142 plant buildings that comprise the Naugatuck plant. Not very impressive from the outside, the pilot plant contains some of the most modern equipment in the chemical industry. Inside is a maze of complex piping, sophisticated reactors, and control systems.

Makes Chemicals For Plant

The pilot plant, operated by the Research and Development department, serves as a small scale plant to evaluate new processes and manufacture other products. It also produces low volume chemicals where it would not be economical to build a plant and manufactures several intermediate chemicals which cannot be purchased commercially but are required for the plant’s overall operations. New experimental chemicals are also made by the pilot plant for evaluation by our customers, universities, and the agricultural industry to help develop new markets for us.

“Alar” Made In Plant

A large production run of Alar Tech was recently completed. This new growth regulent prevents apples from dropping off the trees and increases their storage life. An alar-like chemical produced by the pilot plant is Cyclohexanone, another agricultural chemical, used in the manufacture of Omite*, a new insecticide.

SAFETY IS MY RESPONSIBILITY

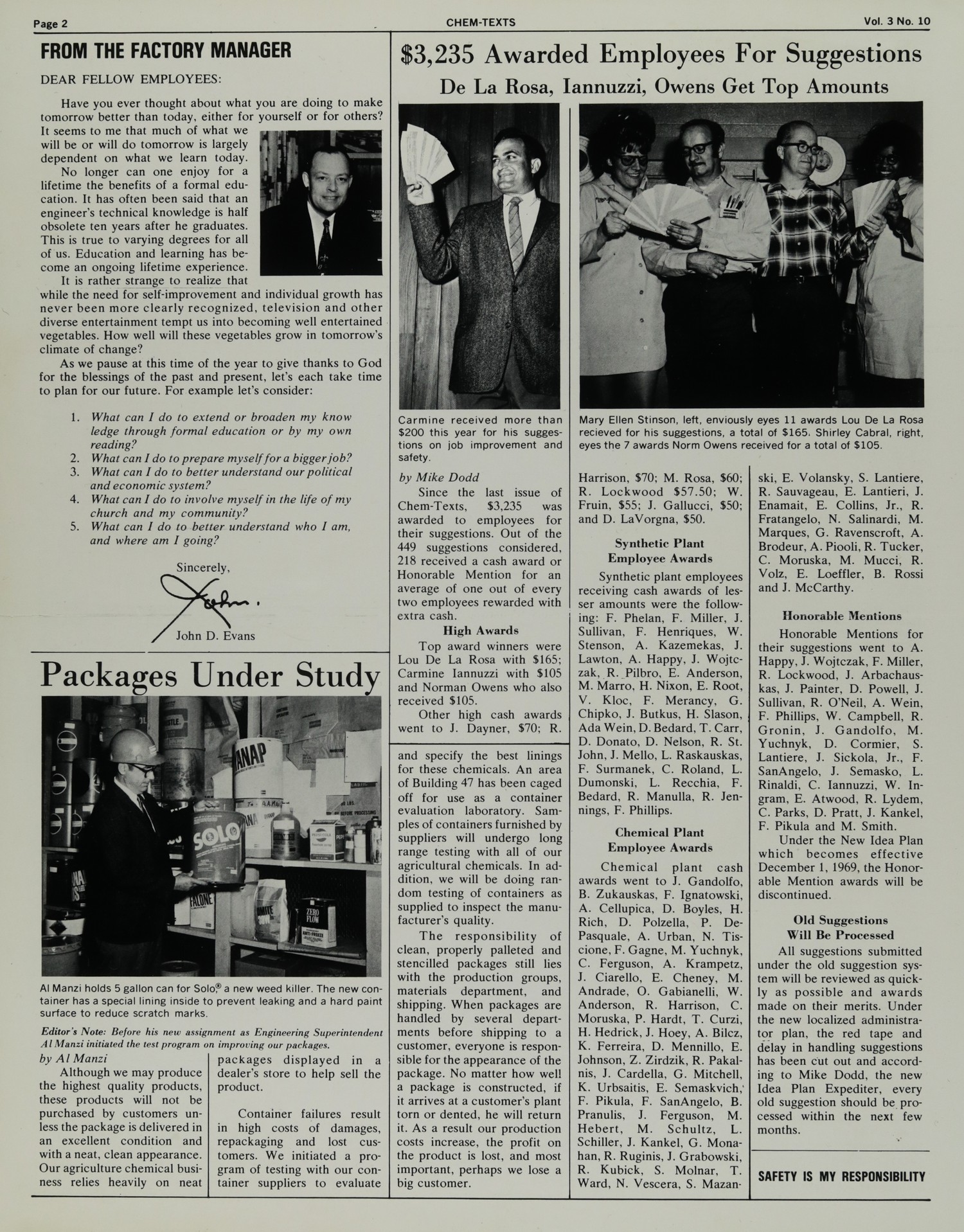

Ben Pranulis, left, and Fran San Angelo operate basket centrifuge that increases their storage life. Another chemical produced by the pilot plant is Cyclohexanone, an agricultural chemical, used in the manufacture of Omite*, a new insecticide.

Improves Safety And Production

The pilot plant contains some of the most modern, expensive equipment in the chemical industry to help us produce better quality products. A year ago a newly purchased Centrifuge Dryer was installed, the only one of its kind here in Naugatuck. Its purpose was not only to increase the production of Alar, but also to handle the solvent recovery in the process safely with a new mechanical seal agitation and automatic temperature control was recently installed to improve product quality and make the operator’s job easier.

Good Morale, Housekeeping

Good morale is hard to define but it’s clearly evident among the people who work in the pilot plant. A cheerful, cooperative atmosphere exists and the worker-supervisor attitude helps take the boredom out of the daily routine of the job that everyone experiences. Also noticeable when you enter the pilot plant is the good housekeeping condition of the area. Materials and drums are properly arranged and rubbing is free of trash and rubbish.

Working in the plant which operates three shifts around the clock are Joe Founder, Bob Emanuel, Hans Defelson, Fran Pikula, Dan Pinto, John Layden, Julius Cohen, Marcel Herbert, Chris Owens, Al Grella, Tony Ciffone, Fran SanAngelo, Jerry Ferguson, Ben Pranulis, Casimiro Pereira. Other members of the group are Don Bates and Julius Rek, foreman; and Bronnis Zaluslkas, materials supervisor. Group Leader for the Chemical Pilot Plant is Colin Walker.

—

## Page 002

FROM THE FACTORY MANAGER

DEAR FELLOW EMPLOYEES:

Have you ever thought about what you are doing to make tomorrow better than today, either for yourself or for others? It seems to me that much of what we will be or will do tomorrow is largely dependent on what we learn today. No longer can one enjoy for a lifetime the benefits of a formal education. It has often been said that an engineer’s technical knowledge is half obsolete ten years after he graduates. This is true to varying degrees for all of us. Education and learning has become an ongoing lifetime experience.

It is rather strange to realize that while the need for self-improvement and individual growth has never been more clearly recognized, television and other diverse entertainment tempt us into becoming well entertained vegedatas. How well will these vegedatas grow in tomorrow’s climate of change?

As we pause at this time of the year to give thanks to God for the blessings of the past and present, let’s each take time to plan for our future. For example let’s consider:

1. What can I do to extend or broaden my knowledge through formal education or by my own self-improvement?

2. What can I do to prepare myself for a bigger job?

3. What can I do to better understand our political and economic system?

4. What can I do to involve myself in the life of my church and my community?

5. What can I do to better understand who I am, and where and what I am going?

Sincerely,

John D. Evans

Packages Under Study

Al Manzi holds 5 gallon can for Solo’s a new weed killer. The new container has a special finish inside to prevent leaking and a hard surface to reduce scratch marks.

Editor’s Note: Before the tests announced at Engineering Superintendents. Al Manzi initiated this test program on improving our packages.

Although we may produce the highest quality products, these products will not be purchased by customers unless the package is delivered in an excellent condition and with a neat, clean appearance. Our packaging chemical business relies heavily on neat and specific the best linings for these chemicals. As a result, our production costs increase, the profit on the product is lost, and most important, perhaps we lose a customer.

Container failures result in high costs of damages, repackaging and lost customers. We initiated a program of testing with our container suppliers to evaluate and specify the best linings for these chemicals. In addition, we will be doing random checks on production as a contained evaluation laboratory. Samples of containers furnished by suppliers will undergo long range testing with all of our agricultural chemicals. In addition, the effects of containers as supplied to growers compared to the same empty containers under laboratory conditions will be evaluated.

The responsibility of clean, properly palletted and stenciled packages still lies with the production groups, materials department, and engineering. Careful handling of packages are handled by several departments, and finally the customer, everyone is responsible for the appearance of the package. No matter how well a package is constructed, if it arrives at a customer’s plant torn or dented, he will return it. As a result our production costs increase, the profit on the product is lost, and most important, perhaps we lose a customer.

$3,235 Awarded Employees For Suggestions

De La Rosa, Iannuzzi, Owens Get Top Amounts

[Image of three employees receiving awards]

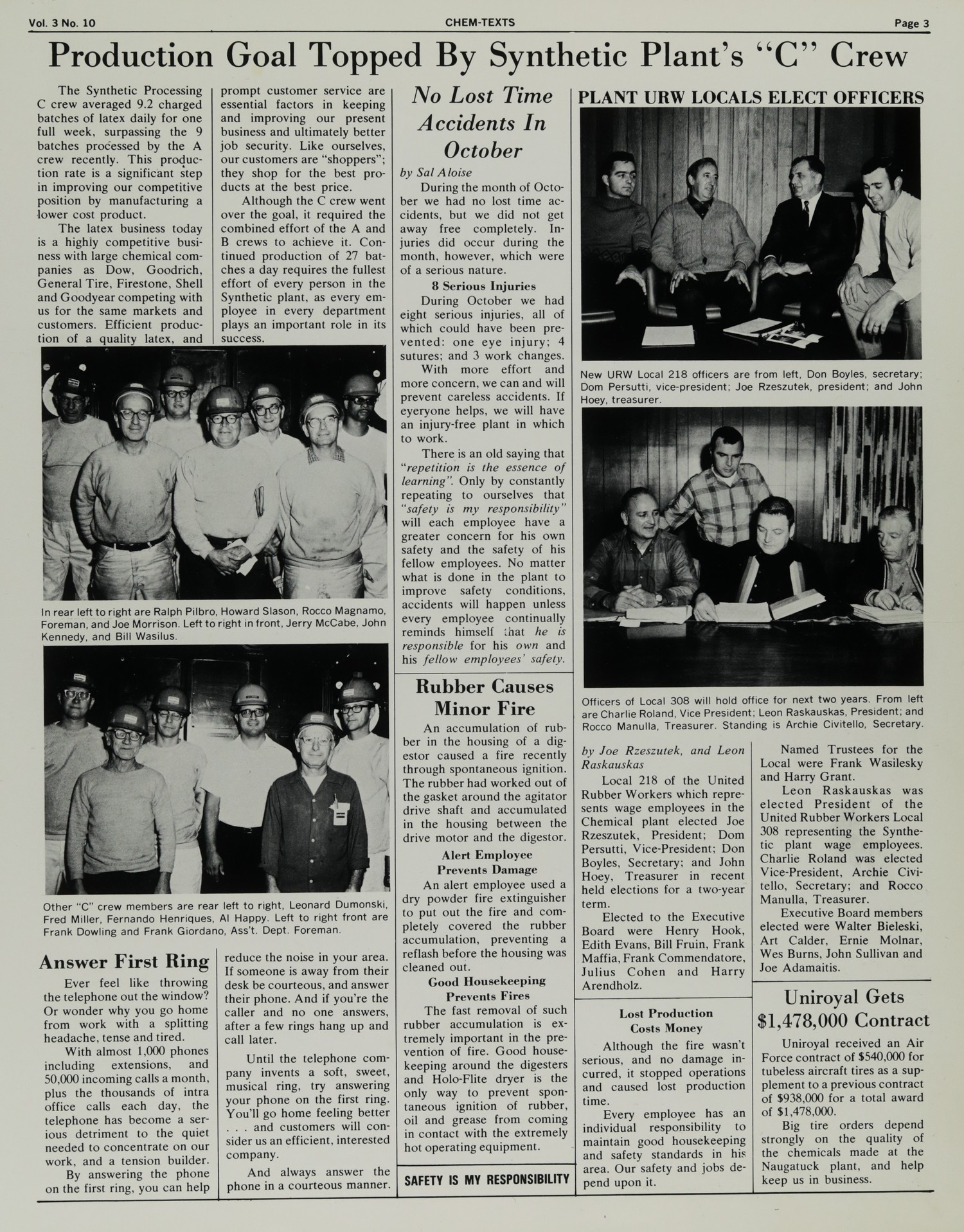

Carmine received more than $200 this year for his suggestions on job improvement and safety.

Since the last issue of Chem-Texts, $3,235 was awarded to employees for their suggestions. Out of the 449 suggestions considered, 218 received a cash award or Honorable Mention for an average of one out of every two suggestions rewarded with extra cash.

High Awards

Top award winners were Lou De La Rosa with $105, Carmine Iannuzzi with $105 and Norman Owens who also received $105.

Other high cash awards went to J. Dayner, $70; R. Volonsky, $. Lantiere, E. Enamati, E. Collins, Jr., R. Frattangelo, M. Enright, A. Marques, G. Ravescroft, A. Brodeur, A. Piolli, R. Tucker, C. Moruska, M. Macci, R. Volz, E. Loeffler, B. Rossi and J. McCarthy.

Honorable Mentions

Honorable Mentions for their suggestions went to A. Jackson, J. Wojtcizak, J. Mitter, R. Lockwood, J. Auerbach, L. Parkin, D. Rowell, J. Sullivan, R. O’Neil, A. Wein, F. Phillips, W. Campbell, R. Gronin, J. Gandolfo, M. Yachnyk, D. Conner, S. Lantiere, J. Siclola, Jr., F. SanAngelo, J. Semasko, L. Rinaldi, G. Iannuzzi, W. Ingram, E. Atwood, R. Lyden, C. Parks, D. Pratt, J. Kankel, F. Pikula and M. Smith.

Chemical Plant

Employee Awards

Chemical plant cash awards went to J. Gandolfo, B. Zukauskas, J. Pignatowski, A. Cellupica, D. Boyles, H. Rich, D. Pozella, P. De Pasquale, A. Urban, N. Tiscione, F. Gagne, W. Mychnyk, F. Ferguson, A. Krampez, J. Carello, E. Cheney, M. Anderson, O. Chinaelli, W. Meeks, P. Mitchel, T. Golebieski, C. Harrison, C. Petroff, J. Roberts, G. Bellino, R. Feeney, J. Ferreira, D. Memillo, E. Johnson, Z. Roszi, R. Palarino, J. Cardella, G. D. Mitchell, K. Heilinsk, E. Semaskevich, F. Pikula, F. SanAngelo, B. Herbert, J. Ferguson, M. Knapp, L. Schultz, J. Kankel, G. Monahan, R. Ruginis, J. Grabowski, T. Ward, N. Vescera, S. Mazanec.

Synthetic Plant

Employee Awards

Synthetic plant employees receiving cash awards of lesser amounts were the following: F. Phelan, F. Miller, J. Sullivan, F. Henriques, W. Stenson, A. Kazemekas, J. Lawton, A. Haury, J. Wojciak, R. Pulbro, E. Anderson, M. Marro, H. Nixon, E. Root, T. Kloc, F. Merandy, G. Gizipo, J. Burkas, H. Slason, A. De Vita, D. Bedard, T. Carr, D. Dorato, D. Nelson, R. St. John, J. Mello, H. Reskauskas.

Under the New Idea Plan which becomes effective December 1, 1969, the Honorable Mention awards will be discontinued.

Old Suggestions

Will Be Processed

All suggestions submitted under the old suggestion system will be reviewed as quickly as possible and awards made on their merits. Under the new Incentive or Plan, the red tape and delay in handling suggestions will be eliminated. The old suggestion boxes will be removed as soon as possible according to Mike Dodd, the Idea Plan Coordinator. Any old suggestion should be forwarded within the next few months.

SAFETY IS MY RESPONSIBILITY

—

## Page 003

Here is the text extracted from the document image, preserving the layout and structure as much as possible:

Vol. 3 No. 10 CHEM-TEXTS Page 3

Production Goal Topped By Synthetic Plant’s “C” Crew

The Synthetic Processing

C crew averaged 9.2 charged

batches of latex daily for one

full week, surpassing the 9

batches processed by the A

crew recently. This production rate is a significant step

in improving our competitive

position by manufacturing a

lower cost product.

The latex business today

is a highly competitive business with large chemical companies as Dow, Goodyear,

General Tire, Firestone, Shell

and Goodyear competing with

us for the same markets and

customers. Efficient production of a quality latex, and

prompt customer service are

essential factors in keeping

and improving our present

business and ultimately better

job security. Like ourselves,

our customers are “shoppers”;

they shop for the best products at the best price.

Although the C crew went

over the goal, it required the

combined effort of the A and

B crews to achieve it. Continued production of 27 batches a day requires the fullest

effort of every person in the

Synthetic plant, as every employee in every department

plays an important role in its

success.

No Lost Time PLANT URW LOCALS ELECT OFFICERS

Accidents In

October

by Sal Aloise

During the month of October we had no lost time accidents, but we did not get

away free completely. Injuries did occur during the

month, however, which were

of a serious nature.

In rear left to right are Ralph Pilbro, Howard Slason, Rocco Magnano,

Foreman, and Joe Morrison. Left to right in front, Jerry McCabe, John

Kennedy, and Bill Vasillis.

Other “C” crew members are as rear left to right, Leonard Dumonski,

Fred Miller, Fernando Rodriquez. At Happy: Left to right front are

Frank Dowling and Frank Giordano, Ass’t. Dept. Foreman.

8 Serious Injuries

During October we had

eight serious injuries, all of

which could have been prevented: one eye injury; 4

sutures; and 3 work changes.

With more effort and

more concern, we can and will

prevent careless accidents. If

everyone helps, we will have

an injury-free plant in which

to work.

“There is an old saying that

‘repetition is the essence of

learning’. Only by constantly

repeating to ourselves that

‘safety is my responsibility’

will each employee have a

greater concern for his own

safety and the safety of his

fellow employees. No matter

what is done in the plant to

improve safety conditions,

accidents will happen unless

every employee continually

reminds himself that ‘he is

responsible for his own and

his fellow employees’ safety.’

Rubber Causes

Minor Fire

An accumulation of rubber in the housing of a digester caused a fire recently

through spontaneous ignition.

The rubber had worked out of

the gasket around the agitator

drive shaft and accumulated

in the housing, between the

drive motor and the digester.

Alert Employee

Prevents Damage

An alert employee used a

dry powder fire extinguisher

to put out the fire and completely covered the rubber

accumulation, preventing a

reflash before the housing was

cleaned out.

Good Housekeeping

Prevents Fires

The fast removal of such

rubber accumulation is extremely important in the prevention of fire. Good housekeeping around the digesters

and floor-line drives is the

only way to prevent spontaneous ignition of rubber

oil and grease from coming

in contact with the extremely

hot operating equipment.

SAFETY IS MY RESPONSIBILITY

New URW Local 218 officers are from left, Don Boyles, secretary,

Don Persuti, vice-president: Joe Reszutiak, president, and John

Hoey, treasurer.

Officers of Local 308 will hold office for next two years. From left

are Charlie Roland, Vice President; Leon Raskauskas, President; and

Rocco Manilla, Treasurer. Standing is Archie Civello.

Named Trustees for the

Local were Frank Wasilesky

and Harry Grant.

Leon Raskauskas was

elected President of the

United Rubber Workers Local

308 representing the Synthetic plant wage employees.

Charlie Roland was elected

Vice-President, Archie Civello, Secretary; and Rocco

Manilla, Treasurer.

Elected to the Executive

Board were Henry Hook,

Edith Evans, Bill Frum, Frank

Maffia, Frank Commendator,

Julius Cerutti and Harry

Arendholz.

Uniroyal Gets

$1,478,000 Contract

Uniroyal received an Air

Force contract of $549,000 for

tubeless aircraft tires as a supplement to a previous contract

of $938,000 for a total award

of $1,478,000.

Big tire orders depend

strongly on the quality of

the chemicals made at the

Naugatuck plant, and help

keep us in business.

—

## Page 004

Page 4

CHEM-TEXTS

Sales Set Record; Profits Drop 10.5%

Sales of Uniroyal, Inc. set new records for the thirty-nine weeks ending September 26, 1969, but profits failed to keep pace with sales and took a 10.5% drop.

Sales for the nine month period totaled $1,165,502,000, compared with $1,060,659,000 reported for 1968. Profits were $38,184,000, equivalent to $1.33 a share of common stock, 10.5% lower than the $42,650,000 or $1.55 a share for 1968.

The third quarter sales for 1969 were $368,869,000 compared to $341,874,000 for 1968 and net income was $8,292,000 equivalent to 27 cents a share compared with $13,768,000 or 45 cents a share last year. Third quarter earnings in 1969 were based on a greater number of shares outstanding.

Profits were hurt by increasing inflationary factors, including rising costs for wages and raw materials, as well as higher interest rates on borrowed capital.

The Company also encountered abnormally high production costs for new tire constructions and greater start-up expenses for new and expanded production facilities.

Contact Lenses

Are Unsafe

by Bob Short

Many employees are not

fully aware of the dangers in

wearing contact lenses in the

plant.

Chemicals and dusts

which enter the eye and work

their way behind the lens cannot be washed out until the

lens is removed. Very often

permanent damage to the eye

can result before this can be

done.

There is a rule which is

included in the Laboratory

Safety Manual stating: Contact Lenses are not to be

worn in the plant. For your

own safety and to prevent

injury to eyesight, it is extremely important to observe

this rule.

Dividend Declared

Uniroyal declared a dividend of 17-1/2 cents a share

on its common stock. It will

be payable December 24 to

stockholders of record on

November 24.

This payment will bring

total dividends paid on the

stock in 1969 to 70 cents a

share.

Approximately 65% of the

Naugatuck plant employees

are stockholders or participants in the Stock Purchase

Plan.

Clergy Visit Parishioners

During a recent plant tour, local clergy had a chance to see their

parishioners at work. Talking a coffee break during the tour they chat

with Neil Melore, Industrial Relations Supervisor. From left are John

Letts YMCA Director, Rev. Clark Kuntzeler, Rev. Robert Hankins, Rev.

James Daughran and Melore. With back to camera is Rev. Robert

Baker.

Luggage Ideal Xmas Gift

Sabia, Buckingham Retire

Smart looking luggage,

ideal for Christmas gifts, is

made from Kralastic ABS, a

tough impact resistant plastic,

a product of the Chemical

Division. Manufactured by

several quality luggage companies, the cases can withstand the roughest abuse a

traveller can give them.

Davidle which is the Consumer and Industrial Sales representative for ABS sheet

material, displays a sight of

aluminum and just oneseventh the weight of steel.

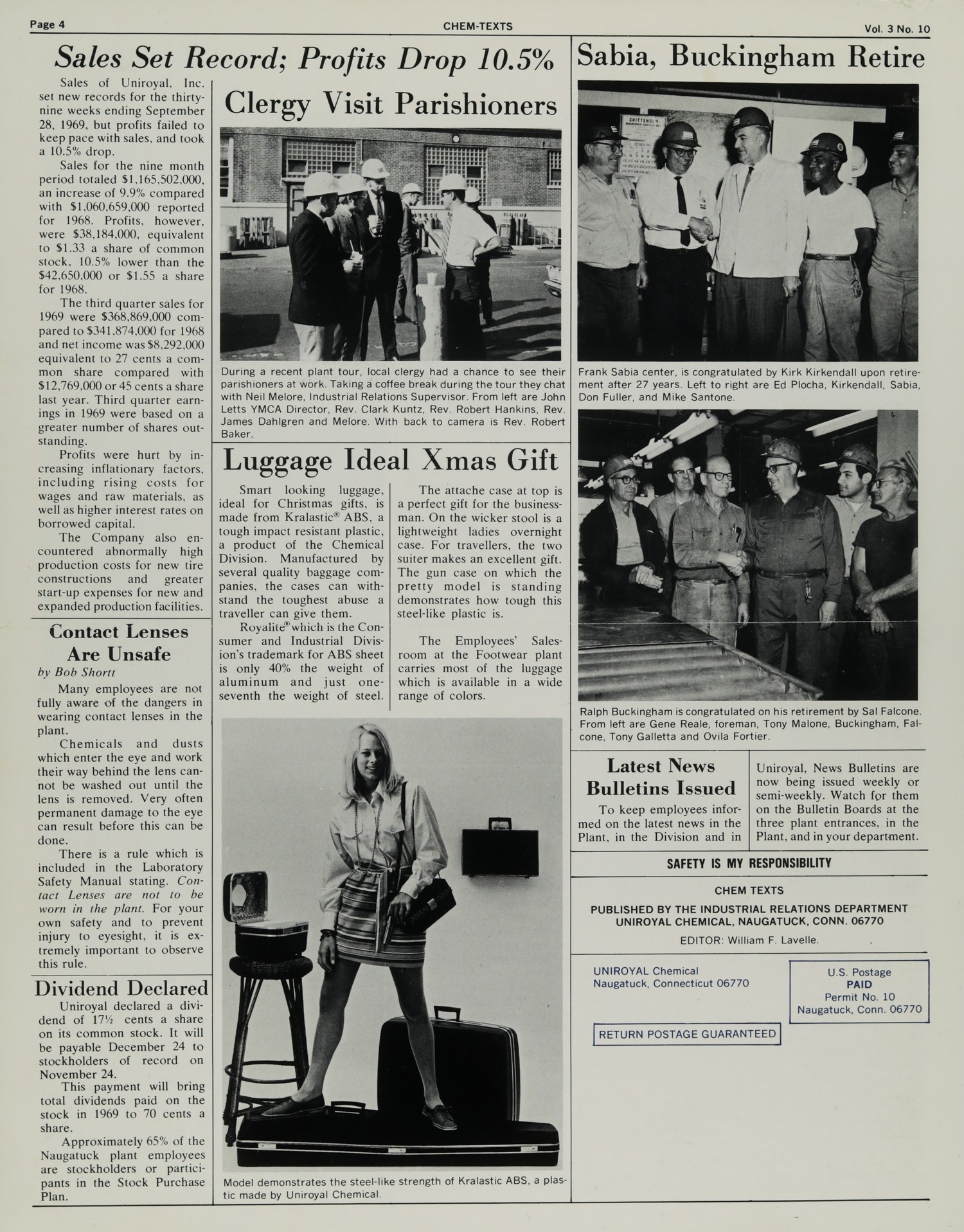

Frank Sabia, center, is congratulated by Kirk Kendall upon retirement after 27 years. Left to right are Ed Piocha, Kendall, Sabia,

Don Fuller, and Mike Santone.

Ralph Buckingham is congratulated on his retirement by Sal Falcone.

From left are Gene Reale, foreman, Tony Malone, Buckingham, Falcone, Tony Galietta and Ovila Fortier.

Latest News

Bulletins Issued

To keep employees informed on the latest news in the

Plant, in the Division and in

the Company.

The Employee’s Sales.

room at the Footwear plant

carries most of the luggage

which is available in a wide

range of colors.

SAFETY IS MY RESPONSIBILITY

CHEM TEXTS

PUBLISHED BY THE INDUSTRIAL RELATIONS DEPARTMENT

UNIROYAL CHEMICAL, NAUGATUCK, CONN. 06770

EDITOR: William F. Layette

UNIROYAL Chemical

Naugatuck, Connecticut 06770

U.S. Postage

PAID

Permit No. 10

Naugatuck, Conn. 06770

RETURN POSTAGE GUARANTEED

Model demonstrates the steel-like strength of Kralastic ABS, a plastic made by Uniroyal Chemical.

Uniroyal News Bulletins are

now being issued weekly or

semi-weekly. Watch for them

on the Bulletin Boards at the

three plant entrances, in the

canteens and in your department.

—