## Page 001

UNIROYAL

CHEM-TEXTS

Vol. 4, 1970

PUBLISHED FOR THE PEOPLE OF UNIROYAL CHEMICAL

1970 Success Depends On Each Employe

If you were going on a

long vacation you would care-

fully plan in advance and con-

sider everything necessary

for a safe and rewarding trip

for yourself and your family.

Operation of a large

chemical plant requires the

same deliberate planning in

advance to assure progress,

produce products competi-

tively, improve safety and to

secure the jobs of every em-

ployee.

To implement the plans

of the plant for 1970, millions

of dollars will be invested by

the Company proving its con-

fidence in the skills and abili-

ties of the people at Naugatuck. Mere spending of money

will not do the job alone; only

the fullest use of every em-

ployees efforts in every de-

partment is needed to justify

these expenditures. With a

positive attitude and concern

by each employee to do his

full share, 1970 will be a year

of progress.

Departments Depend

Upon Each Other

Each department outlined

plans and goals for the year

for its own group. But the

success of these plans require

the cooperative effort of all

departments. Progress de-

pends upon every employee’s

fullest cooperation to work

in a unified effort with all the

departments in the plant’s

operation.

The following summarize

the major plans for depart-

ments to make 1970 a year of

progress.

Chemical Production

Product quality and pro-

duction must be improved to

satisfy our customers’ de-

mands. Their purchase of our

products are critically im-

portant to the operation of

the plant.

To help us improve this

situation, the new Control

Center will schedule products

by priority; help improve pro-

duct quality and utilize equip-

Improvements in house-

keeping by all employees is

of vital importance to main-

tain safe working conditions

and to keep quality standards

of latex production at a high

level.

Engineering

The engineering depart-

ment’s plan in ’70 will be to

assist all departments in the

repair and maintenance of

equipment to prevent down-

time and insure the capacity

to supply customers with pro-

ducts on schedule.

Efficient operation of

machinery and equipment re-

quires regular lubrication by

members of the mechanical

crews to prevent excessive

wear, even overheating and

damage to vital parts. It is

necessary to produce the pro-

ducts for our customers.

Several major plant im-

provements are scheduled in

the Synthetic and Chemical

plants.

George Allen, ass’t general foreman discusses new Polygard facilities

for Bldg. 109. From left are Allen, Mike Yuchynk, Dolphi Gabriel,

dept. foreman, and Benny Kontaygoe.

ment to its fullest capacity.

This new operation requires

everyone’s cooperation to im-

prove our performance in

1970.

Special concern is given to the

department that better safety

and housekeeping standards

can only be accomplished by the

individual person doing his

share.

Plans have been approved

to expand the Polygard®

Antioxd and Reanol® facilities

to meet increased market de-

mand for these chemicals.

Reclaim Production

Reclaim faces a challeng-

ing year but with the vigorous

participation of every em-

ployee in attaining produc-

tion goals the challenge can be met

to operate the plant effici-

ently and remain in business.

A new Control Center

will be set up to schedule

product types more efficiently

and to help improve the qual-

ity of reclaim.

Good housekeeping is

critically important in Re-

claim to prevent fires from

dust accumulation around

machines and for general

safety. Concern for good

housekeeping in Reclaim re-

quires every employe’s help

to keep the area in a clean

condition.

Lighting fixtures and the

lint collection systems are

scheduled to be improved for

better safety, housekeeping

and work conditions.

Synthetic Production

New equipment will be

installed to increase the ef-

ficiency of our latex oper-

ations to increase production,

produce higher quality latexes

to keep pace with competition

and provide job security.

Contract Talks

To Start

Plant and union officials

of Uniroyal’s 19 United Rub-

ber plants meet in

New York City on March

to begin negotiations on con-

tract agreements which ex-

pire April 20th.

Ron Mitchinson, indus-

trial relations manager, will

represent the Naugatuck

Chemical plant. Joe Reszutek, president of URW

Local 218, will represent the

218 employees in the Chem-

ical and Synthetic plants and

the Research Lab.

URW Local 218, representing

the 201 employees of the

Synthetic plant.

Negotiations will cover

wages, pension, the master

contract, insurance, sever-

ance pay agreements and sup-

plemental unemployment

compensation.

United Givers Give 3 Awards

Left to right holding United Givers awards are Leon Reszutek,

URW Local 218 president; Eric Johnson, plant campaign chairman;

and Joe Reszutek, URW Local 218 president.

At its annual meeting,

the United Givers awarded a

plaque in recognition of Uni-

royal Chemical employee’s

generous contributions.

Plaques were also awarded

to URW Locals 218 and 308’s

for their active support of

the drive.

Employees’ contributed

$21,000, the highest ever

pledged, in our plant, nearly

a third of the industrial divi-

sion’s goal.

The corporate gift of the

plant was the highest of any

local firm in Naugatuck and

Beacon Falls.

—

## Page 002

FROM THE FACTORY MANAGER

DEAR FELLOW EMPLOYEE:

Recently I was pleased to announce to the general public that our Management has approved funds to construct waste pre-treatment facilities at our plant. This expenditure of close to $300,000, along with successful negotiations of an agreement with the Borough of Naugatuck to provide secondary treatment of our wastes, will bring us a long way in meeting our obligations to help clean up the Naugatuck River.

However, I am very much concerned that each of us realize our individual part in doing the total job to control pollution. No matter what Management does or spends on pollution control facilities, these actions will never be effective unless every employee shows a personal concern to eliminate pollution in his activities.

We all have to face up to our individual responsibilities to avoid spills, careless dumping of spoiled materials and excessive flushing of processing areas. In practice, we have to operate on the basis that the drain is the very last alternative for disposal.

We can not wait for the new treatment plans before we start to operate in this manner. We have to learn right away that water pollution control is not just another project – everybody must do their part – we are all coming on to the job!

John D. Evans

“Mountain Moved”, Improves Safety, 3 Acres Added

by Pete Thomas

What was once a “mountain” in the middle of the plant has been moved to the rear during the past nine weeks and is now three acres of flat usable land.

Falling rocks on the steep banks on the west side of Buildings 73, 107W and 106 made it impossible to get heavy equipment into this location from the plant yard area or at the top of the bank.

In the discussions with five different contractors about this problem, an agreement was made with the Waterbury Sand and Gravel Company to remove and level the top of this high bank between Building 75 and the Synthetic Pilot Plant at no charge to Uniroyal Chemical for the privilege of keeping all the gravel to process.

$615 Awarded For Suggestions

Zates line in Bldg. 89 which will increase productivity, provide a smoother operation and improve product quality.

Marty Hebert was awarded $85 based on his suggestion to reduce cycle time on the CHO still in Bldg. 72 by hookup.

Other high awards went to Charlie Ferguson, $150, Carmine Ianuzzi, $100, and Walter Wronski, $75. Cash awards were also received by Pete Shreder, Dan Cleary, Tim Clark, John Emanuel, Sam Molinari, Jerry Ferguson, Ken Ferreira, Mary Marques, Al Krampetz, Mike Yurchyak, Len Recchia, Charles Rolland, Dan Donato, Ray Jennings, Andy Molnar, Jean Burke and Ben Tomaszeski.

Honorable Mentions went to Frank Patt, Ted Hubbell, Tony Rebelo, Bob Lockwood, and John Thompson.

These awards were made on the old Suggestion System. Bernie Daily, the New Idea Plan coordinator, is making every attempt to clear up all outstanding Suggestions and at the same time speed up the red tape and delay in handling the new Idea Plan.

There’s been a major improvement in handling Ideas; some because of their complexity require more time; others take less time. Ideas are worth $1,000 … and more.

The minimum award is $25.

Scoop digs away “mountain” between Bldg 75 and Synthetic pilot plant.

Land Now Usable

When this project is completed, the plant will be able to bring in a crane at the top of the leveled bank to remove the large loose rocks which created a safety hazard.

We will also have three acres of level and suitable for future use.

Pete Thomas checks the finished job which will improve plant safety.

—

## Page 003

HOPKINS PREDICTS A TOUGH, CHALLENGING 1970

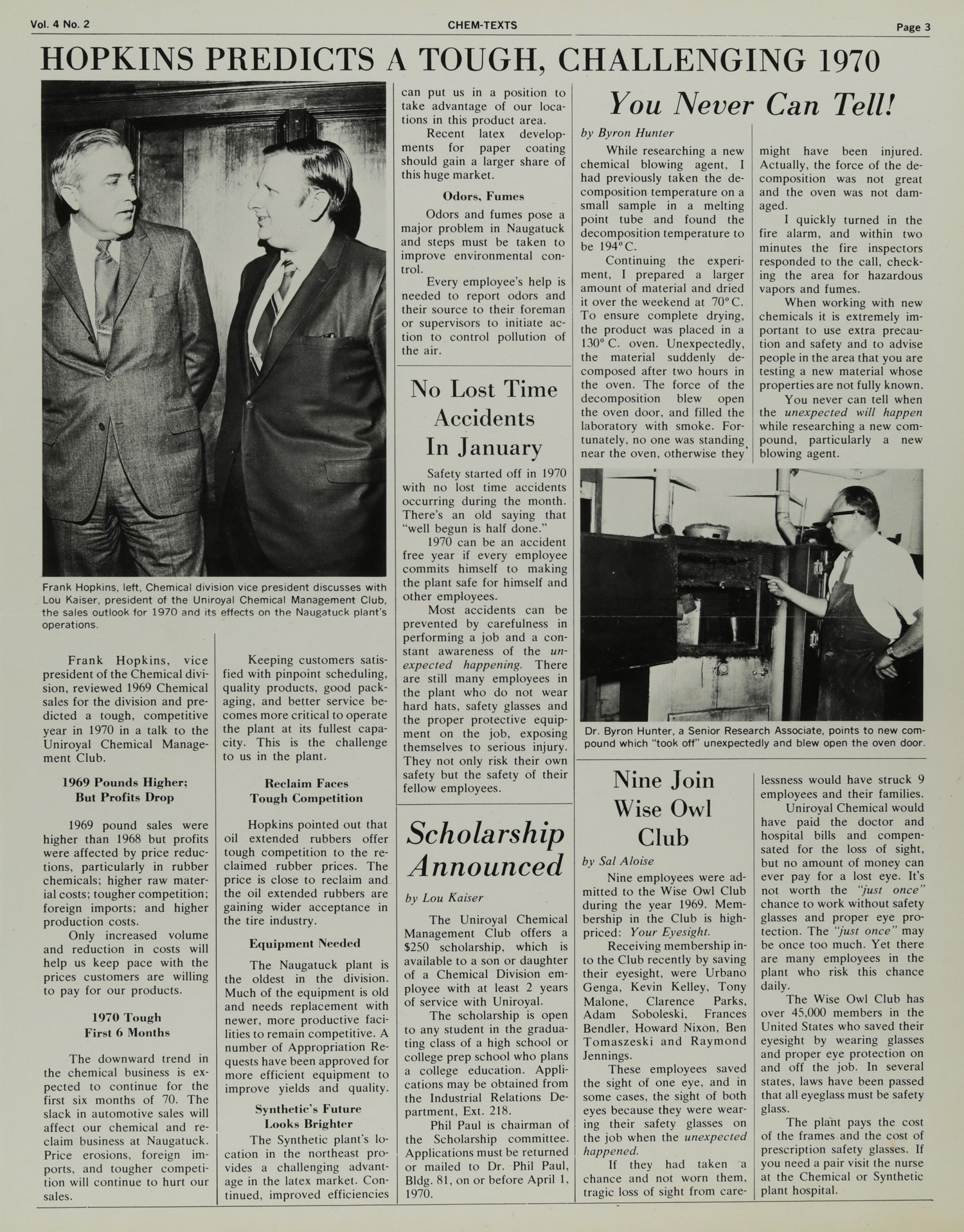

Frank Hopkins, vice president of the Chemical division, reviewed 1969 Chemical sales for the division and predicted a tough, competitive year in 1970 in a talk to the Uniroyal Chemical Management Club.

1969 pound sales were higher than 1968 but profits were affected by price reductions, particularly in rubber chemicals; better raw material costs; tougher competition; foreign imports; and higher production costs.

Only increased volume and reduction in costs will help us keep pace with the prices customers are willing to pay for our products.

1970 Tough

First 6 Months

The downward trend in the chemical business is expected to continue for the first six months of ’70. The slack in automotive sales will affect our chemical and reclaim business at Naugatuck.

Price erosions, foreign imports, and tougher competition will continue to hurt our sales.

You Never Can Tell!

by Byron Hunter

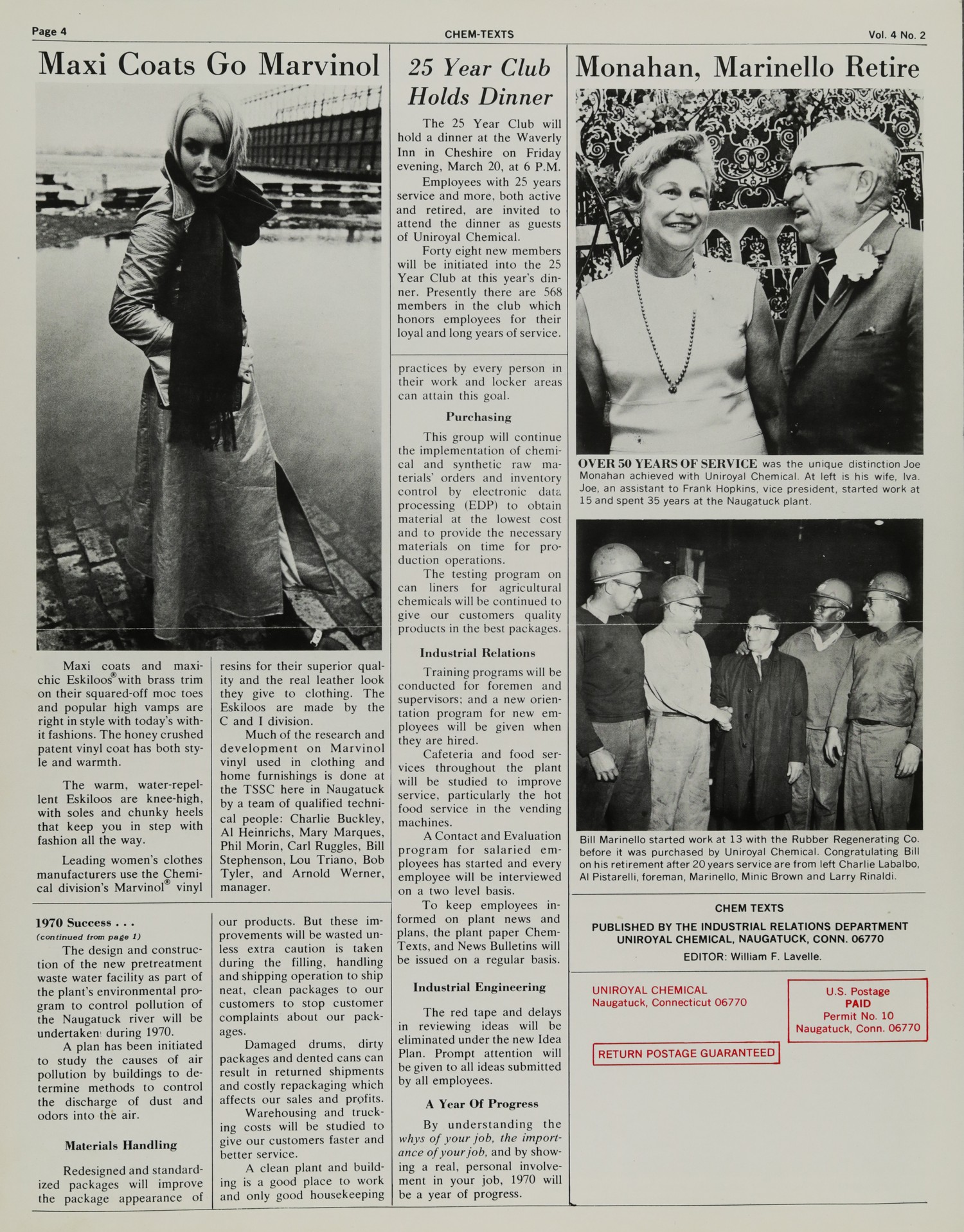

While researching a new chemical blowing agent, I had previously taken the decomposition temperature on a small sample in a melting point tube and found the decomposition temperature to be 194°C.

Continuing the experiment, I prepared a larger amount of material and dried it over the weekend at 70°C. To ensure complete drying, the product was placed in a 130°C oven. Unexpectedly, the material suddenly decomposed after two hours in the oven. The force of the decomposition blew open the oven door, and filled the laboratory with smoke. Fortunately, no one was standing near the oven, otherwise they might have been injured.

Actually, the force of the decomposition was not great and the oven was not damaged. But within two minutes the fire inspectors responded to the call, checking the area for hazardous vapors and fumes.

When working with new chemicals it is extremely important to use extra precaution and safety and to advise people in the area that you are testing a new material whose properties are not fully known.

You never can tell when the unexpected will happen while researching a new compound, particularly a new blowing agent.

No Lost Time Accidents In January

Safety started off in 1970 with no lost time accidents occurring during the month.

There’s an old saying that 1970 can be an accident free year if every employee commits himself to making the plant safe for himself and other employees.

Most accidents can be prevented by carefulness in performing a job and a constant awareness of the unexpected happening.

There are still many employees in the plant who do not wear hard hats, safety glasses and the proper protective equipment on the job, exposing themselves to serious injury.

They not only risk their own safety but the safety of their fellow employees.

Scholarship Announced

by Sal Aloise

Uniroyal Chemical Management Club offers a $250 scholarship, which is available to a son or daughter of a Chemical Division employee with at least 2 years of service with Uniroyal.

The scholarship is open to any student in the graduating class of a high school or college prep school who plans to attend a college or university education. Applications may be obtained from the Industrial Relations Department, Bldg. 218.

Phil Paul is chairman of the Scholarship committee. Applications must be returned and mailed to Dr. Phil Paul, Bldg. 81, on or before April 1, 1970.

Nine Join Wise Owl Club

by Sal Aloise

Nine employees were awarded membership in the Wise Owl Club during the year 1969. Membership in the Club is highlighly prized: Your Eyesight.

Recent memberships in the Club were Urbano Genga, Kevin Kelley, Tony Malotic, Lawrence Parks, Adam Soboleski, Frances Benedit, Howard Nixon, Ben Tomaszeski and Raymond Jenkins.

These employees saved the sight of one eye, and in some cases, the sight of both eyes because they were wearing their safety glasses on the job when the unexpected happened.

If they had not taken a chance and not worn them, tragic loss of both from careless eye protection may have resulted.

The plant pays the cost of the frames and the cost of prescription safety glasses. If you need a pair visit the nurse at the Chemical or Synthetic plant hospital.

can put us in a position to

take advantage of our locations in this product area.

Recent latex developments for paper coating should gain a larger share of this huge market.

Odors, Fumes Pose a

major problem in Naugatuck

and steps must be taken to

improve environmental control.

Every employee’s help is

needed to report odors and

their source to their foreman

or supervisors to initiate action to control pollution of

the air.

No Lost Time

Accidents

In January

Safety started off in 1970

with no lost time accidents

occurring during the month.

There’s an old saying that

1970 can be an accident

free year if every employee

commits himself to making

the plant safe for himself and

other employees.

Most accidents can be

prevented by carefulness in

performing a job and a constant awareness of the unexpected happening. There

are still many employees in

the plant who do not wear

hard hats, safety glasses and

the proper protective equipment on the job, exposing

themselves to serious injury.

They not only risk their own

safety but the safety of their

fellow employees.

Scholarship

Announced

by Sal Aloise

Uniroyal Chemical

Management Club offers a

$250 scholarship, which is

available to a son or daughter

of a Chemical Division employee with at least 2 years

of service with Uniroyal.

The scholarship is open

to any student in the graduating class of a high school or

college prep school who plans

to attend a college or university education. Applications may be obtained from

the Industrial Relations Department, Bldg. 218.

Phil Paul is chairman of

the Scholarship committee.

Applications must be returned

and mailed to Dr. Phil Paul,

Bldg. 81, on or before April 1,

1970.

Nine Join

Wise Owl

Club

by Sal Aloise

Nine employees were awarded membership in the Wise Owl Club

during the year 1969. Membership in the Club is highlighly prized: Your Eyesight.

Recent memberships in the Club were Urbano Genga, Kevin Kelley, Tony Malotic, Lawrence Parks, Adam Soboleski, Frances Benedit, Howard Nixon, Ben Tomaszeski and Raymond Jenkins.

These employees saved the sight of one eye, and in

some cases, the sight of both eyes because they were wearing their safety glasses on the job when the unexpected happened.

If they had not taken a chance and not worn them, tragic loss of both from careless eye protection may have resulted.

The plant pays the cost of the frames and the cost of prescription safety glasses. If you need a pair visit the nurse at the Chemical or Synthetic plant hospital.

—

## Page 004

Maxi Coats Go Marvinol

25 Year Club Holds Dinner

The 25 Year Club will hold a dinner at the Waverly Inn in Cheshire on Friday evening, March 20, at 6 P.M. Employees with 25 years service and more, both active and retired, are invited to attend the dinner as guests of Uniroyal Chemical.

Forty eight new members will be initiated into the 25 Year Club at this year’s dinner. Presently there are 568 members in the club which honors employees for their loyal and long years of service.

Maxi coats and maxi-chic Eskiwool with brass trim on their sophisticated moc toes and popular high vamps are right in style with today’s with-it fashions. The honey-crushed patent vinyl coat has both style and warmth.

The warm, water-repellent Eskiwool are knee-high, with soles and chunky heels that keep you in step with fashion all the way.

Leading women’s clothes manufacturers use the Chemical division’s Marvinol vinyl for their superior quality and the real leather look they give to clothing. The Eskiwools are made by the C and I division.

Much of the research and development on Marvinol vinyl used in clothing and home furnishings is done at the TSSC here in Naugatuck by a team of qualified technical people: Charlie Buckley, Al Heinrichs, Mary Marques, Phil Morin, Carl Ruggles, Bill Stephenson, Lou Triano, Bob Tyler, and Arnold Werner, manager.

1970 Success . . .

(continued from page 1)

The design and construction of the new pretreatment and waste water facility as part of the plant’s environmental program to control pollution by building up the causes of air pollution by buildings to determine methods to control the discharge of dust and odors into the air.

Materials Handling

Redesigned and standardized packages will improve the package appearance of our products. These improvements will be wasted on the extra cost packaging, handling and filling. Damaged drums, dirty packages and dented cans can result in returned shipments and costly repackaging which affects our sales and profits.

Warehousing and trucking costs will be studied to give our customers faster and better service.

A clean plant and building is a good place to work and only good housekeeping practices by every person in their work and locker areas can attain this goal.

Purchasing

This group will continue the implementation of chemical and synthetic raw materials’ orders and inventory control by electronic data processing (EDP) to obtain material at the lowest cost and to provide the necessary materials on time for production operations.

The testing program on can liners for agricultural chemicals will be continued to give our customers quality products in the best packages.

Industrial Relations

Training programs will be conducted for foremen and supervisors; and a new orientation program for new employees will be given when they are hired.

Cafeteria and food services throughout the plant will be studied to improve service, particularly the hot food and vending machines.

A Contact and Evaluation program for salaried employees has started and every employee will be interviewed on a two level basis.

To keep employees informed on plant news and plans, the plant paper Chem Texts, and News Bulletins will be issued on a regular basis.

Industrial Engineering

The red tape and delays in reviewing ideas will be eliminated under the new Ideas Paper. Prompt attention will be given to all ideas submitted by all employees.

A Year Of Progress

By understanding the ways of your job, the importance of your job, and by showing a real, personal involvement in your job, 1970 will be a year of progress.

Monahan, Marinello Retire

OVER 50 YEARS OF SERVICE was the unique distinction Joe Monahan achieved with Uniroyal Chemical. At left is his wife, Ms. Joe, an assistant to Frank Hopkins, vice president, started work at 15 and spent 35 years at the Naugatuck plant.

Bill Marinello started work at 13 with the Rubber Reclaiming Company before it was purchased by Uniroyal Chemical. Congratulating Bill at retirement are (l. to r.) Al Pistareili, foreman, Marinello, Marie Brown and Larry Rinaldi.

CHEM TEXTS

PUBLISHED BY THE INDUSTRIAL RELATIONS DEPARTMENT

UNIROYAL CHEMICAL, NAUGATUCK, CONN. 06770

EDITOR: William F. Lavelle

U.S. Postage

PAID

Permit No. 10

Naugatuck, Conn. 06770

RETURN POSTAGE GUARANTEED

—