## Page 001

UNIBOYAL

CHEM-TEXTS

Vol. 4, 1970 PUBLISHED FOR THE PEOPLE OF UNIBOYAL CHEMICAL No. 6

Plans For New Food Dyanap Sales Increase

Staffing Service For

Oxford The Plant

Underway by C. Durkin by Fred Winzler

Uniboyal’s program for Servomation, Inc. recentcreating a new administrative ly assumed operation of plant

center has been carefully de- food services at the Chemical

veloped to insure that all is Canteen, Synthetic Cafeteria,

ready for the move to Oxford EMB and the vending ma-

in mid-1971. chines in all buildings.

People are always the With headquarters in

most important part of any New Haven, Servomation

program. When present em- offers improved food ser-

ployees in New York City vices, fresh foods, more effi-

were asked, quite a number cient maintenance of the food

told their managers that they machines, a better menu with

do not plan to transfer to a wider selection of hot meals

Connecticut. The gap be- with an eye on the nutritional

tween the number needed and value for weight conscious

the number moving must be customers.

filled by local people. The Chemical plant was

Promotion Policy: one of the last major firms in

Whenever possible, pro- the Valley to retain the 10c

motion from within is a policy coffee but increased whole-

that Uniboyal applies every- sale food prices have forced

where. In the Oxford case it an increase to 15c.

Servomation is one of the

leading food service organi-

zations in Connecticut serving

many firms and schools in the

State with their main facilities George O’Brien, with hat on, R & D product development manager for Dyanap examines field of weed-

only an hour from the plant. free soybeans with a group of chemical division agronomists and State University weed specialists.

There should be considerable His recommendation of a products affects the sale of a herbicide greatly.

improvement in food services

on all shifts and weekends as

a result of the change.

“SAFETY IS MY RESPONSIBILITY”

‘Dyanap’s the “chemical

bloom”, stops weeds before

they emerge from the ground.

George O’Brien, with hat on, R & D product development manager for Dyanap examines field of weed-

free soybeans with a group of chemical division agronomists and State University weed specialists.

His recommendation of a products affects the sale of a herbicide greatly.

Made in Bldg. 73, Dyanap

is a combination of dinitro

and Alanap. It controls a wide

range of broadleaf weeds and

annual grasses that reduce

crop yields 20% to 30% in soy-

beans and peanuts.

16,000,000 Acre Market

“Dyanap” is one of 3 her-

bicides made in the plant;

Alanap” and Solo” being the

other two. 15,000,000 acres of

soybeans and 1,000,000 acres

of peanuts are grown in the

southeast and the midsouti,

a huge potential market for

Dyanap sales and additional

business for the plant.

“Bright Spot in Economy

Agribusiness” is one of

the few bright spots in today’s

economy. With most of the

chemical industry facing stiff

competition and business set-

backs, the agricultural chemi-

cal business has shown steady

growth.

Competition Stiff

The business is a “one

month” shock, if quality, pack-

aging, service or delivery is

poor, competition gets the

business, often for good.

A farmer can’t purchase

Dyanap before planting time,

he buys his herbicide from one

of five major companies:

Amchem, Elanco, Monsanto,

Dupont or Shell. Farming to-

day is big business, with many

growers planting 2,000 – 3,000

acres and investing $100,000

in herbicides, fertilizers, and

machinery.

He shops for the best pro-

duct at the best price and the

best service. His investment

is too risky to take chances

with poor quality and poor

service.

New Products Important

A research and develop-

ment group at the Behainy

Lab of Bob Graham, Adam

Soboleski, Everett Barron and

Ron Ames (now in Liberia)

are continually seeking new

types of herbicides to keep up

competitive in the market.

Field agronomists are

Continued on page 4

means that an interested

salaries employee, presently

in a Chemical Division office

position, who is qualified for

a position at Oxford that is

in a higher skill classification

than is available in the Nauga-

tuck offices, will be given con-

sideration for transfer. Other

Uniboyal people in this area

will have the same oppor-

tunity.

Survey by Questionnaire

During the month of July,

local Chemical Division sal-

aried female office employees

are being asked to complete

questionnaires to determine

who believe they have skills

above the requirements of

their present assignments and

might be interested in transfer

to the Oxford office.

Replies will be reviewed

by responsible managers who

will consider work history and

skill qualifications to deter-

mine who should receive fur-

ther consideration under the

promotion policy.

A similar procedure will

be followed later when other

salaried position requirements

are developed for positions

which specify advanced know-

how, skill and considerable ex-

perience in specific func-

tions.

John Hoonyotski, area foreman, congratulates chemical operators

Ivan Aubin and Bill Galluguige of Bldg. 73 for excellent job in getting

Dyanap to customers on time. At left is Jim Grove, Bldg. 73 foreman.

Others in shift at time of photo were operators Jim Lynch and Frank

Guzzardi.

—

## Page 002

FROM THE FACTORY MANAGER

DEAR FELLOW EMPLOYEE:

This issue of CHEM-TEXTS announces plans for offering office personnel the opportunity to advance to higher positions at the new Oxford offices. Also discussed, are details on how our new performance review program at the plant works. Last month, CHEM-TEXTS announced plans for the mechanical trades training program to be held at Knynor Tech, starting in the fall. Applications for this program will soon be available to those interested in preparing themselves for these skills.

Each of these programs, as well as many others such as the tuition aid plan, is part of UNIROYAL’S continuing desire to provide all employees every chance to continue to grow in knowledge and skills and to make the most of their talents and abilities.

UNIROYAL recognizes that its future is dependent on the future of its employees. To build a future together, we must not only do our present job in the best possible way, but we must also use our own initiative to improve our job skills, this has been said that “opportunity knocks but once.” I, frankly, doubt this – I think “opportunity is always waiting, not outside the door.”

It’s always waiting for the man who takes the first step to open the door himself.

Best regards,

John D. Evans

New Drink At Canteen

Iced tea and hot coffee is the gourmets new drink served at the Canteen. From left, Helen Giacopelli credits Helen Preskus.

The Chemical plant can-teen offers a new drink during coffee breaks, a unique collection of hot coffee and iced tea, a gourmet’s delight. The origin of the drink is cloaked in mystery. When one of the Helens in the canteen left a large container of iced tea, another of the three Helens inadvertently poured the iced tea into the hot coffee urn. The third blend proved to be an exciting and enjoyable way to eat.

Red Cross Blood Drive Successful

EMIC employees generously supported the annual Connecticut Red Cross Bloodmobile visit sponsored by the plant. The Connecticut Red Cross has helped hundreds of employees and their families over the years. With one of the best blood programs in the country, the bloodmobile itself being free, there is a charge for the Bloodmobiles expenses and the hospitals’ administrative services. In some states a pint of blood costs $50.60 plus the additional charges for services.

Gallon Pins Awarded

Gerry Hennessey received a four gallon pin for his thirty second contribution to this worthwhile cause.

Jim Reynolds and Allen Crapo each received a three gallon pin and Joe Finke received a two gallon pin.

One gallon pins were given to Charles Anderson, Roland Morel, Joe Sauvageau and Fred Winston.

Donors Contributing blood – many for the fifth or more time were K. Allen, J. Chapman, Catherine O’Sullivan, L. McGraw, L. Kozlowski, J. Coburn, Ann McGalister, B. Kennedy, R. Baldwin, B. Pierce, A. Tobias, L. Lombardi, C. Bilikas, M. Gallante, E. Emmerich, P. Dillon, E. Phillips, M. Chamberlain, J. Paige, R. Cornell, R. Mastronardi, Alvarado Gent, M. Sutton, R. Stark, H. Nixon, P. Fitzgerald, E. Nolie, D. Williamson, P. Braudis, B. Fisher, Jr., F. Carriero, P. A. Welch, R. Breton, R. Palmer, K. Hughes, K. Harsch, F. Leary, J. McCarthy, Karen DiDonizio, D. Smith, Lucille Macalusso.

Gallon givers are awarded pins by the Red Cross nurse: Gerry Hennessey, 4 gal.; Annette Perseault, 2 gal.; N. Frone from left; are Karen Di Donizio, Lucille Burtur, Hank Deylies, Fred Winston, Annette Della Scientia, Hal Smith, John Gill, and unidentified donor. From right, unidentified donor, Al Smith, Len Bors, Walt Campbell, hidden, Mitt Makoski and Don Powell, hidden. Employees gave generously to the recent Bloodmobile.

$35,261

Lost In

Five Fires

During 1969 the plant had 20 reportable fires. Five of these fires resulted in estimated losses of $35,261. This high amount represents only the damage caused to the equipment and buildings. Several of the fires shut down production lines resulting even in higher losses and increased manufacturing costs. The fires also increased the insurance costs to the plant as rates are based on the damage caused by fire.

Chemical Production had 4 fires with no loss. Reclaim Production had 10 fires, 7 with no loss and 3 with an estimated loss of $30,335. Synthetic Production suffered 4 fires: 3 with no loss and one which cost $4,626. Research and Development had 2 fires: one with an estimated loss of $300 in the Chemical pilot plant.

In 1968 the plant was awarded a plaque for its excellent fire prevention record; but 1969 brought several fires, many attributable to poor housekeeping and safety practices.

Fires can be prevented only if everyone shows his fullest concern for good housekeeping and safety practices in his work area. Fires increase the cost of our products, hurt our pocketbooks and affect job security.

SAFETY IS MY RESPONSIBILITY

—

## Page 003

Vol. 4, No. 6

CHEM-TEXTS

Page 3

Employees’ Opinions Polled On Chem-Texts Unions

A poll of 200 employees selected on a random basis from all plant and division employees revealed that 96% of the employees read CHEM-TEXTS and that 70% of their families read it. The survey also showed the plant newspaper as a reliable form of communication and indicated employees have a vital concern for news and information on plant activities and operations.

70 employees completed the questionnaire for a 35% return, and the signed questionnaire which was voluntary.

An analysis of the “detailed” questions have been condensed because of space limitations.

1) Do you read Chem-Texts?

Ans: 96% always, 4% often, 3% seldom

2) Does your family read Chem-Texts?

Ans: 70% yes, 30% no

3) What kind of news do you find most informative?

Ans: 75% preferred news about plant activities: plant products; use of products in the market; new facilities; plant improvements; personnel changes; and economic situations. 60% wanted news about employees; benefits; idea awards; safety; job security and retirements.

4) How did you like the recent article on the Oxford complex?

Ans: The majority commented “excellent”, “informative”, “indicative of Uniroyal’s progress”, “knew very little about it until article.”

5) Do you think the paper uses enough photographs?

Ans: 80% yes, 18% no

6) What did you think of the article on pollution?

Ans: “Wonderful that something is being done:” “informative on serious pollution problem:” “good to keep us informed on pollution control efforts:” “shows company is concerned and cares;” “must be aware of their role in pollution control.”

7) Some time back we did an article on packaging – do you think this type of information is helpful to employees?

Ans: Most employees replied “yes”, pointing out that it as customers always shop for a neat package.

8) Do you think the paper gives you reliable information on plant operations and activities?

Ans: Some commented “yes”, and others implied, “haven’t gotten any harm from it.”

9) What do you think of the News Bulletins issued weekly?

Ans: Several employees felt the News Bulletins were considered informative and helpful, but several employees did not see them; a few felt they should contain more news on safety and production.

10) What suggestions do you have to improve CHEM-TEXTS?

Ans: The majority of employees had no recommendations to improve the paper. Some remarks suggested: do more articles on departments; more about employees’ participation in community; letters to the editor; classified ads; questions and answers from employees.

The survey was the first conducted in the Company on plant newspapers, and employees who participated are thanked for their time in making it a more effective means of communication.

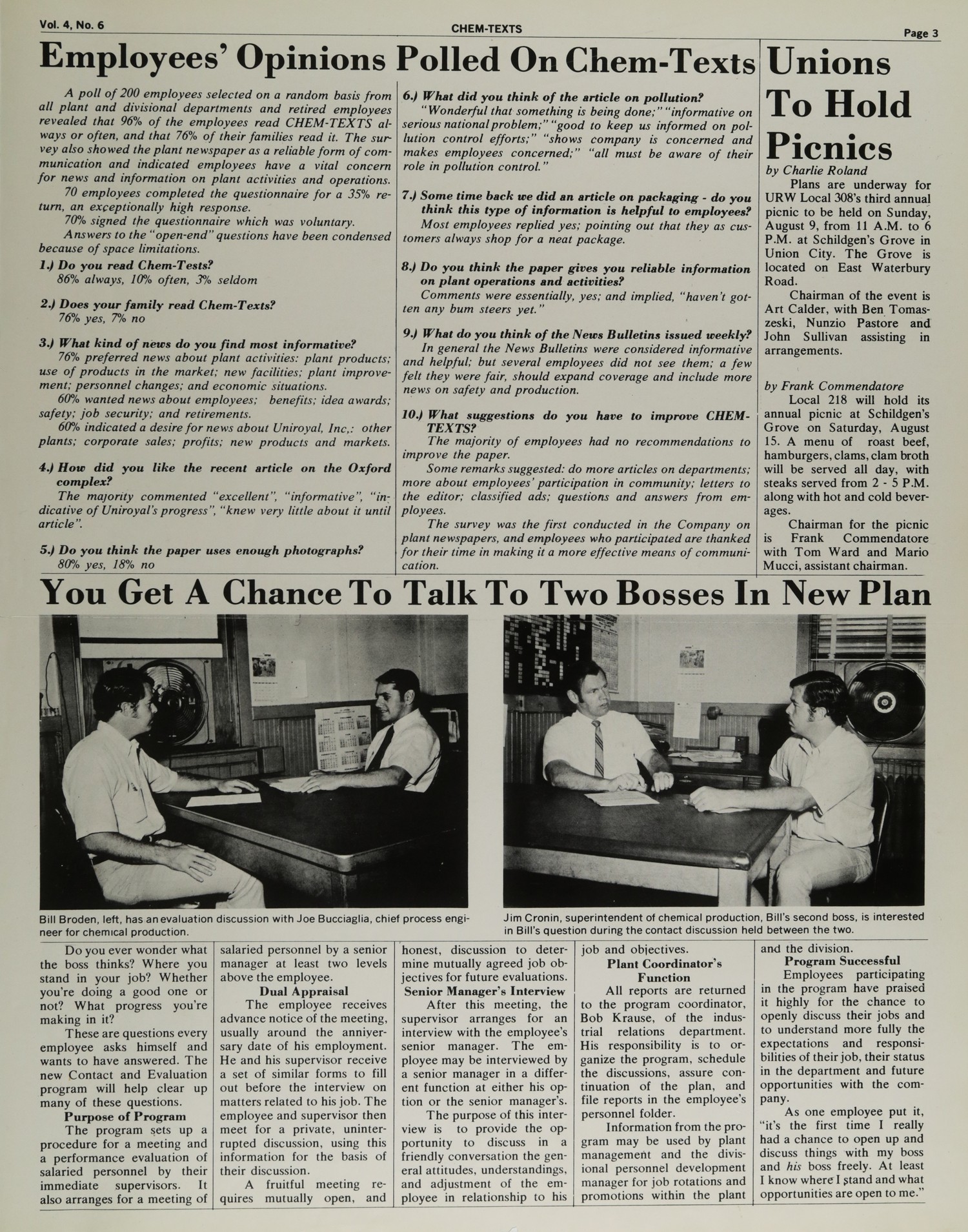

You Get A Chance To Talk To Two Bosses In New Plan

[The image contains two photos of people in an office environment. The captions read:

“Bill Broden, left, has an evaluation discussion with Joe Buccaglia, chief process engineer for chemical production.”

“Jim Cronin, superintendent of chemical production, Bill’s second boss, is interested in Bill’s question during the contact discussion held between the two.”]

The new Evaluation Program gives all employees an opportunity to advance notice of the meeting, usually around the anniversary date of his employment. He and his supervisor receive a set of similar forms to fill out before the interview on matters related to his job. The employee and supervisor then meet for a private, uninterrupted discussion, using this information for the basis of their discussion.

A fruitful meeting for mutual understanding and insight on the relationship between the individual and his supervisor or manager’s function. All reports are returned to the Coordinator who will review of Bill Krause, of the industrial relations department. His responsibility is to organize the program, schedule the discussions, assure continuation of the plan, and file reports in the employee’s personnel folder. Information from the program may be used by plant management and the divisional personnel development manager for job rotations and assignments within the plant.

As one employee put it, “it’s the first time I really had a chance to open up and discuss things with my boss and his boss freely. At least I know where I stand and what opportunities are open to me.”

—

## Page 004

Dust Collectors Overtake The Odds; George Rusnak Retires Synthetic Bowlers Best D&S Team

The Dust Collectors swept under the Synthetic Odds in the roll-off of the Atomic Bowling League in a climactic season-end finish which matched Bob Ruegger, Sam Molnar, Bob Sheldon, Ray Drapeau and Jim Mullen of the Dust Collectors against Clay Houseknecht, John Butkus, Gary McGee, John Jokulbatis, and Don Powell of the Odds. The Collectors took 1st half honors and the Odds won the 2nd half, but the met defeat in the roll-off.

Bob Ruegger won the 1st half prize for a high average of 118.6 and the 2nd. half prize for high three with 417.

Others participating in the league, which is sponsored by Uniroyal Chemical, were R. Valentine, A. Pistorelli, Butler, M. Perkins, Flynn, G. Salokas, R. Magnanimo. A. DaSilva, R. Gogolewski, B. Urelly, N. Pesche, H. Like, M. Mucci, and M. Fioranelli.

New elected officers for 1970-71 season are Don Jokulbatis, president; Jim Fenton, vice president; Dick Valentine, treasurer; and Sam Molnar, secretary.

George Rusnak, center, a pipefitter in the mechanical department is congratulated by Leo Napolitio on his retirement after 32 years service. Department members are from left, Mario Mucci, Napolitio, Tom Ward, and Dick Clark.

Autos, Major Cause Of Air Pollution

by Bob Shortt

Motor vehicles, primarily automobiles, account for approximately 70% of the total estimated tonnage of air pollution discharged annually into Connecticut air.

20% of the total suspended particulate matter, 98% of the total carbon monoxide, and 49% of the total hydrocarbons.

personnel John Casey, Bill Credo, Tony Marquez, Jim Brolin and Tono San Angelo played a big role in getting orders to customers on time – sometimes overnight during the hectic season.

Excellent service, a quality product, and good packaging keeps customers, and in the long run customers keep the plant operating at full capacity.

30 gallon Dynap drums in warehouse 76 are checked for dents, scratches and labeling by, from left, Jim Noha, Tony Marqules and Tono Sam Angelo, the last three people in the plant to handle a package before it’s shipped to a customer.

A big factor in this year’s success of Dynap was Chemical Production operators Jim Lynch, Ivan Ashin, Frank Guzzardi and Bill Gallevege.

Service keeps customers

Protection and delivery of materials required fast handling and expert routine by the Materials Handling department during the critical rush orders. A package is handled 10 times before it ever leaves the plant, and only expert care prevents damage to it. Customers are choosy buyers and on several occasions have returned truckloads of damaged packages, causing a financial loss to the plant.

The “one shot” season is over, but Chemical Shipping personnel played a big role in getting orders to customers on time – sometimes overnight during the hectic season.

Red Cross Cont’d from page 2

Shortt, J. Jokulbatis, E. Fisher, J. Doran, R. Cronin, J. Ascencio, J. Napierlo, W. Rek, I. Sullivan, R. Manilla, E. Semaskivich, W. Albatis, E. Diver, E. Johnson, A. Cross, E. Easterbrook, J. Chimelinski, J. Thompson, J. Mullen, C. Smith, R. Woodfield, A. Fleck, and C. Gandaiila.

PUBLISHED BY THE INDUSTRIAL RELATIONS DEPARTMENT UNIROYAL CHEMICAL, NAUGATUCK, CONN. 06770

EDITOR: William F. Lavelle

U.S Postage,

PAID

Permit No 10

Naugatuck, Conn. 06770

RETURN POSTAGE GUARANTEED

—