## Page 001

UNIROYAL

CHEM-TEXTS

Vol. 4, 1970 PUBLISHED FOR THE PEOPLE OF UNIROYAL CHEMICAL No. 8

Polygard Facilities To Expand

Design drawings are near completion for the expansion of Polygard® facilities in Bldg. 109. The major equipment has been ordered and 75% of the necessary piping materials are on order for the project which will increase the production rates of the chemical. The project is part of the plant’s continuing program to stay competitive in a tight chemical market, keep business at the plant and keep chemical production employment at a full level.

Used In Rubber

Polygard is one of the most effective nondiscoloring and nonstaining stabilizers for synthetic rubber in commercial use today. Without Polygard protection, degradation occurs during the finishing, processing and vulcanization, resulting in a shorter service life of the final rubber product.

As a chemical, Polygard is able to use, having the approval of the Food and Drug Administration (FDA) for use in products used for packaging or handling food.

New Stainless Steel Lines

The major work done during the summer shutdown of the building was the installation and replacing of 2 Hold tanks from the second to the third floor. The piping from the bottom of the four vessels which will eventually become strippers was re placed with much larger stainless steel lines. The transfer pump was relocated and the discharge lines relocated and replaced with 3″ and 4″ stainless steel piping.

Fume Control Devices

When completed in early 1972, the expanded facilities will have environmental control devices to control fume emissions as part of the plant’s policy on the installation of new equipment and engineering controls.

MIP Plan To Start

Instead of the 1970 stock purchase plan slated to start August 1, Uniroyal will expand the Monthly Investment Plan (MIP) to all employees interested in purchasing Uniroyal stock, at the market price, on a regular payroll deduction basis.

Under the plan, which is operated by Merrill Lynch, Pierce, Fenner and Smith, Inc., employees can sign up for regular payroll deductions. There are minimum and maximum deductions which will be indicated with other information, in plan brochures available shortly. Merrill Lynch will purchase Uniroyal stock at the market price and keep individual accounts for each employee. Employees will receive regular statements from Merrill Lynch showing how much stock has been purchased for their accounts.

H.S. Diploma Obtainable

It’s still possible for a person who left high school for one reason or another to obtain a high school diploma without going back to school.

To qualify for a diploma, a person must be 18 years or older and successfully complete the General Educational Development (GED) test battery which is available through many community colleges and adult education programs. The GED test battery covers the main subject areas taught in high school.

Employees Prevent Fire

A cooperative fire fighting group: in front–Pat Tortorici, left to right–Charlie LeBlanc, Millie Brown and Al Morey. Absent from photo–Charlie Rinaldi.

Mimic Brown, Larry Rinaldi, Charlie LeBlanc, Al Morey and Pat Tortorici, acted quickly in extinguishing a small fire in an air screen machine that the sensitive sprinkler system did not operate and the sounding of the plant fire alarm was not required.

The incident occurred when the canvas dust wrapper around the machine ignited and burned. John Needham, left, shows Eric Johnson the High School Equivalency diploma he received upon successful completion of tests. Other employees plan to take the test in September.

Chemical Control Center, The First In Chemical Division

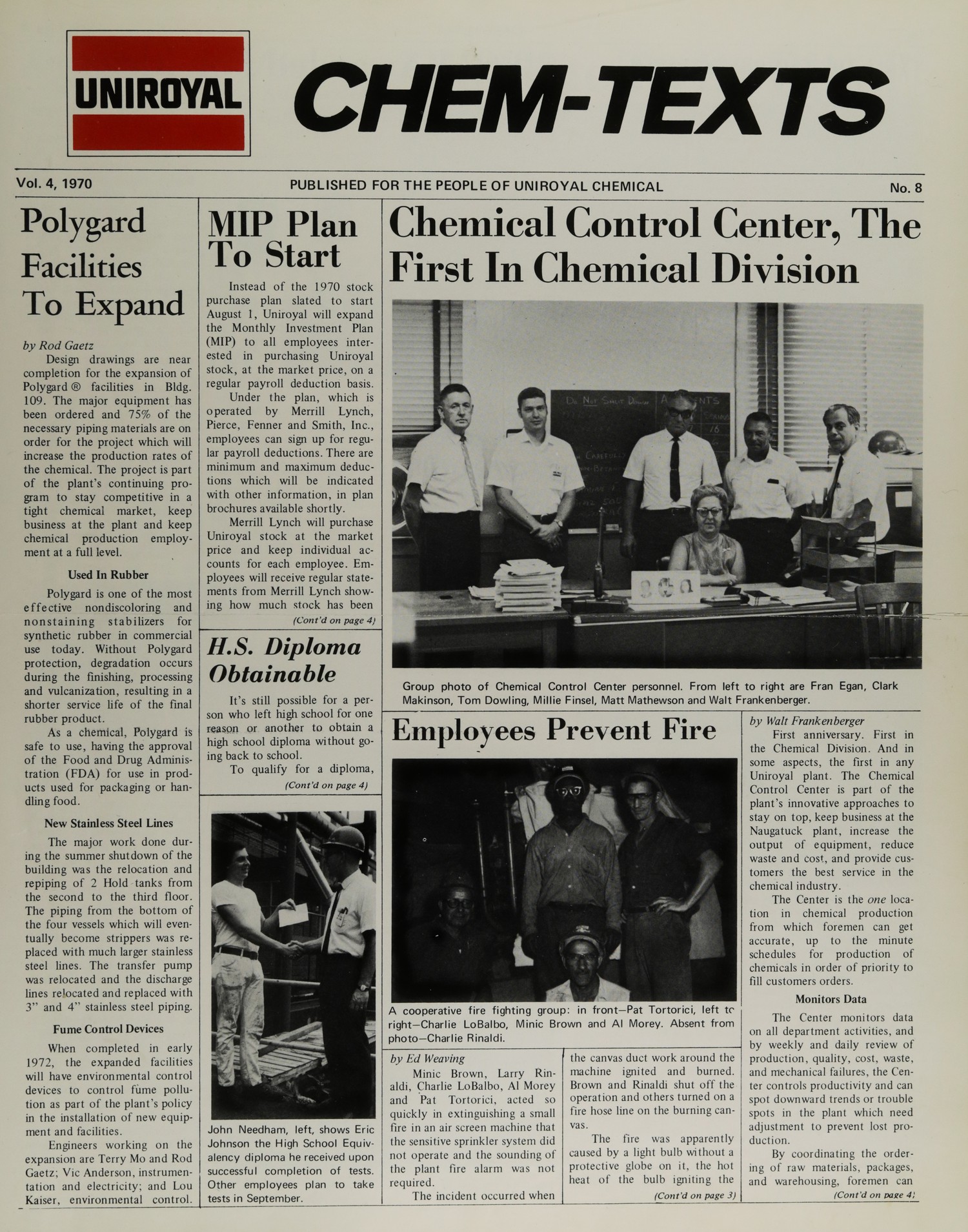

Group photo of Chemical Control Center personnel. From left to right are Fran Egan, Clark Makinson, Tom Dowling, Millie Finsel, Matt Matthewson and Walt Frankenberger.

By Walt Frankenberger

First anniversary. First in the Chemical Division. And in some aspects, the first in any Uniroyal plant. The Chemical Control Center is part of the plant’s innovative approaches to stay on top, keep business at the Naugatuck plant, increase the output of equipment, reduce waste and cost, and provide customers the best service in the chemical industry.

The Center is the one location in chemical production from which foremen can get accurate, up to the minute schedules for production of chemicals in order of priority to fill customers orders.

Monitors Data

The Center monitors data on all departmental activities, and by weekly and daily review of production, quality, cost, waste, and mechanical failures, the Center controls productivity and can provide prompt adjustments to prevent lost production.

By coordinating the ordering of raw materials, packages, and warehousing, foremen can devote more time to production and less to procurement and other ancillary duties.

(Cont’d on page 4)

—

## Page 002

FROM THE FACTORY MANAGER

DEAR FELLOW EMPLOYEE:

I’m certain that the vast majority of us know and appreciate the fact that UNIROYAL CHEMICAL is a good place to work. Sure, we all have our gripes and inconveniences but when we really think about it we’ve got it pretty good. As only one example, the other day I was looking at the average earnings for all production workers in Connecticut and was struck by the fact that our average is $3.31 per hour as compared to $4.00 per hour in our plant. When the effect of premium rates for overtime is considered, the State average is $3.43 per hour and our average is $3.39 per hour.

Beyond pay and the importance of our superior benefit plans, there is the question of what kind of place is it to work? I believe you will agree with me that a very important factor is the “atmosphere” or “climate.” Like productivity, safety, and housekeeping and quality, each of us must be responsible for “climate.” We do this every day by our attitudes, our cooperation and our ability to communicate with each other. To help us recognize this responsibility each of us must listen, as well as talk. Each of us must recognize that others have problems, as well as ourselves.

Concern for the customer, concern for the fellow employee and yes, concern for the job produces results.

Best regards,

John D. Evans

Many Apply For Kaynor

Kaynor Tech offers a broad program of excellent trades courses.

More than 45 employees have applied for the training program to qualify candidates for skilled trades openings in the plant. The 2-year trades courses program will cover: Fundamentals of Arithmetic, Measurements, and Engineering Drawing in the first year.

The second year is tentatively planned to cover: Introduction to Pipe Fitting; Electricity; and Construction Trades.

Successful completion of the program as judged by Kaynor Tech’s instructors will give the candidates the chance to qualify for semi-class trades openings in accordance with present contractual requirements of seniority and qualifications.

Employees applying for the program are: C. Andrews, F. Ahl, R. Bedard, W. Carreira, R. Cheverier, A. Gilcone, F. Douty, J. Dewing, R. Rennant, J. Ferguson, K. Ferreria, F. Gagni, H. Garahan, T. Gladding, T. Griffin, A. Huypy, P. Hunt, S. J. Hurtenit, M. Hebert, G. Hennessey, J. Hose, C. Jackson, J. Kenny, R. Kubick, H. McIsaac, J. Mello, D. Monnillo, F. Miller, E. Molnar, R. Morelo, J. Morrison, J. Needham, H. Nixon, J. Oliveira, R. Osim, D. Polzella, J. Poduone, L. Rechio, F. Santangelo, M. Seymour, F. Simatocki, J. Sordi, J. Sullivan, B. Tomaszeski, L. Watson and E. Zeinit. Other names were unavailable at press time.

$2,634 Awarded For Ideas

by Bernie Daily

$849, one of the highest awards ever given an employee for a suggestion, was presented to Annie Mannion for her late husband’s suggestion to use Kunkle safety valves and springs as standard equipment in the plant. Her husband, Earl, who suffered a heart attack while they were vacationing in Maine, was a first class piper in the mechanical department.

The Kunkle valves and springs reduced material costs, were easier to install and far safer in their operation and are now used throughout the plant.

Other high awards went to Ed Bazenas and Marcel Hebert, who each received $75 for their two suggestions. Fred Miller received $50 for two ideas, and Nelson and Stan Dashak were awarded $50 each for their single ideas and R. Lockwood’s three ideas netted him $50.

An Urban Gisol was an initial award of $50 with his ideas listed under study for a possible higher amount.

$35, $25, $15 Awards

Cash amounts of $35, $25, or $15 were awarded to J. Gandolfo, F. Mayo, W. Cavage, M. DeSousa, D. Beaulieul, W. Chartier, A. Galletta, J. Tully, L. Rizzo, E. Root, J. Rebeghil, M. Carty, F. Surmanek, W. Tabaka, W. Krayeski, F. Guerra, D. LaVorgna, F. Henriques, F. Bendler, H. Pasek, C. Tabore, D. Polzella, J. Enamait, W. Anderson, G. Ravenscroft, J. Barno, O. Huntley, M. Rosa, J. Matcheson, A. DaSilva, C. Molcart, D. Masone, A. Hanley, L. Clark, T. Lee, A. Moura, C. Boland, R. Pronowst, K. Anderson, J. Hunt, A. Lanouette, W. Parks, F. Malfa, F. Pikula, H. Rich, W. Scott, C. Jannuzzi, N. Tessone, J. Chase, R. Lestage, T. Smiegel-ski, J. Cardella, N. Brummet and F. Sordi.

Letters And Mentions

Commendation letters and Honorable Mentions for their ideas and suggestions went to J. Poudrier, C. Wierzbicki, J. Sichenzia, D. Pratt, A. Kasprzak, E. Molnar, J. Painter, J. Butkus, J. Sullivan, J. Gallucci, J. Josa, W. Hill, Jr., L. DelaRosa, F. Rehel, R. Fratangelo, J. Fargasso, L. Taranovich, J. Douty, T. Mo.F. Emmait, F. Engle, R. Malz, Jr., J. Mucha, J. Finke, D. Polzella, T. Huybell, M. Sweeney, F. Commendatore, F. Rosa, M. Yelchnyk, B. Tomaszeski and C. Zawacki.

Ideas pay from $25 to $1000 and higher and are given immediate attention and prompt action by Bernie Daily, coordinator of the Idea Plan, and by the departmental investigators.

Lubrication Program Set

by Ian Racicowski & A. Lamoureux

The new oil room in the Reclaim Plant is the latest step in the continuing program of the engineering and mechanical department to upgrade lubrication techniques and service throughout the plant.

Since contamination is the greatest enemy of oil, a clean storage and dispensing area for lubricants is essential to maintaining high quality service. In addition to being a cleaner area than the previous oil room, the new oil room is centrally located in the Reclaim plant and easily accessible for drum deliveries.

Equipment lubrication is recognized as a critically essential service and serious efforts are being made to maintain a high quality service. A lubrication program is now being developed for the chemical plant.

The lubrication equipment to be store in the new oil room includes the following:

1. The new lubrication cart which employs modern lubrication equipment.

2. Lubrication records as required by the lubrication schedule for the reclaim plant.

3. A central automatic dispensing station, now being installed for the Farval lubricators used in the mill rooms.

Al Manzi, Mechanical Department Superintendent, presents check to Mrs. Bernie Daily, left, Idea Plan Expediter, as they look on approvingly.

—

## Page 003

Here is the extracted text from the document image, preserving the layout and structure as much as possible:

Vol. 4 No. 8 CHEM-TEXTS Page 3

Know Your Benefits:

Some Questions And Answers On

Uniroyal’s Matching Gift Program

by Mill Makoski

To provide and insure a college education for our own children

and the many children who can’t afford one, Uniroyal, Inc., has set

up the Matching Gift Program.

Today colleges need help more than ever before since tuition

charges cover only a part of the cost of an education. These colleges

need help from companies, foundations, and individuals whether

college graduates or not.

Q. What is the matching gift

program?

A. It is a program Uniroyal offers to all employees whereby

the Company will contribute to

institutions of higher education,

amounts equal to contributions

made by employees.

Q. What amounts will Uniroyal

match?

A. The minimum amount is

$25. The maximum gift for each

employee is $1,000 per year.

Q. What employees are eligible?

A. All active employees on regu-

lar full time jobs or on an

authorized leave of absence with

at least one year of service.

Q. What educational institutions

are eligible?

A. All colleges and universities

which grant degrees and which

are recognized by a recognized

agency or are actively

seeking such an accreditation are

eligible.

Q. How should an employee

apply for the matching gift to an

educational institution?

A. The employee obtains an ap-

plication form from the institution

to which he wishes to contribute.

He completes this form and sub-

mits it to the Uniroyal Industrial

Relations Department. Uniroyal

will then match the employee’s

gift.

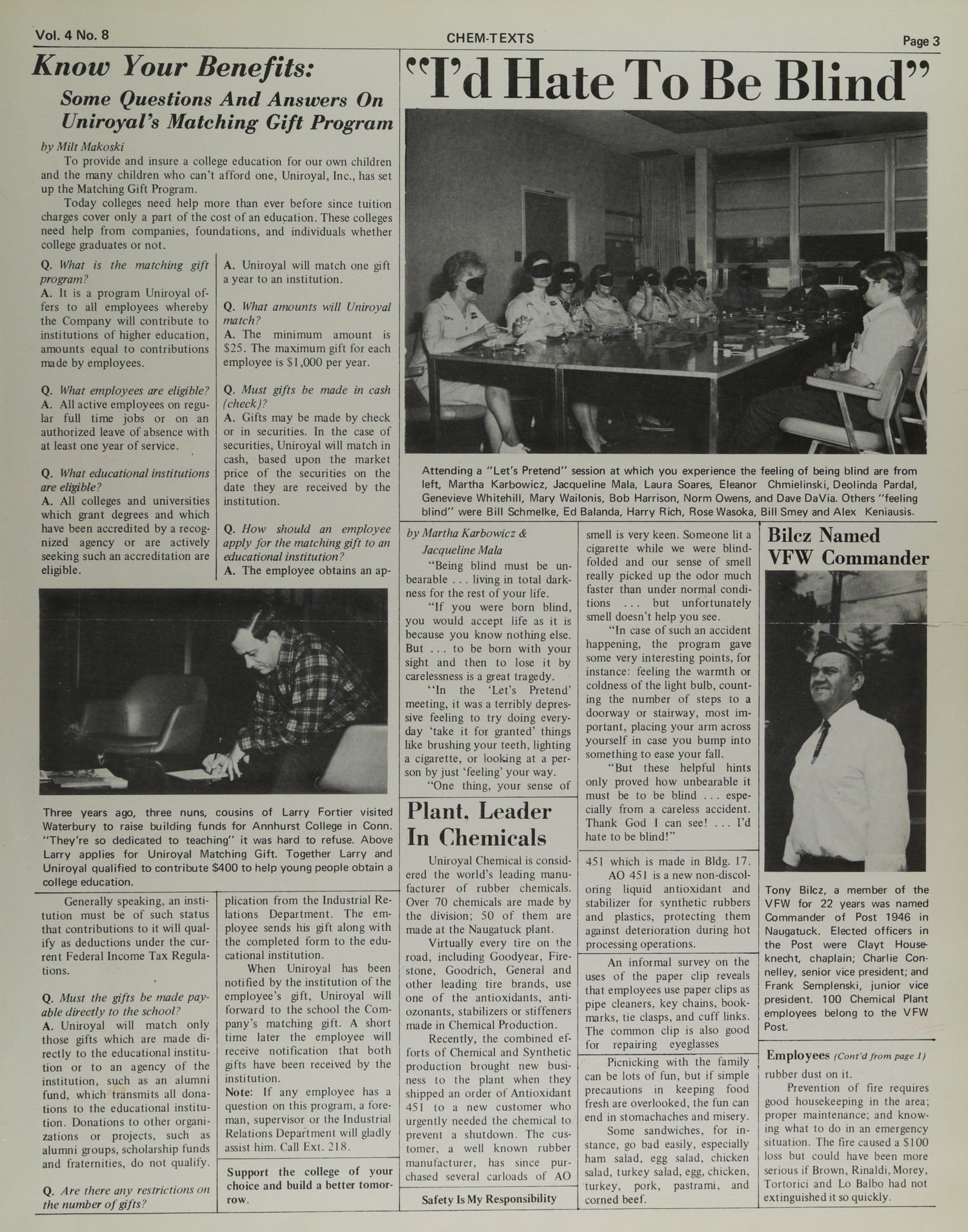

“I’d Hate To Be Blind”

Attending a “Let’s Pretend” session at which you experience the feeling of being blind are from

left, Martha Karbowicz, Jacqueline Mala, Laura Soares, Eleanor Chmielinski, Deolinda Pardal,

Geneviève Whitehil, Mary Waltons, Bob Harrison, Norm Owens, and Dave Davis. Uniting “feeling

blind” were Bill Schmelke, Ed Balanda, Harry Rich, Rose Wasoka, Bill Smley and Alex Keniausis.

by Martha Karbowicz &

Jacqueline Mala

“Being blind must be un-

bearable . . . being in total dark-

ness for the rest of your life.

“If you were born blind,

you would accept life as it is

because you know nothing else.

But . . . to be born with your

sight and then to lose it by

carelessness is a great tragedy.”

“In the “Let’s Pretend”

meeting, it was a terribly depres-

sive feeling to try doing every-

day ‘take it for granted’ things

like brushing your teeth, lighting

a cigarette, or looking at a per-

son by just ‘feeling’ your way.

“One thing, your sense of

Plant, Leader

In Chemicals

Uniroyal is considered the world’s leading manufacturer of chemicals. Over 700 chemicals are made by

the division. 50 of them are made at the Naugatuck plant.

Virtually every tire on the

road, including Goodyear, Fire-

stone, Goodrich, General and

other leading tire brands, use

one of the antioxidants, anti-

ozonants, stabilizers or softeners

made in Chemicals Production.

Recently, the combined ef-

forts of Chemical and Synthetic

Rubber Divisions brought new

business to the plant when they

shipped an order of Antioxidant

451 to a new customer who

urgently needed the chemical to

prevent a shutdown. The cus-

tomer, a well known rubber

manufacturer, has since pur-

chased several carloads of 451

which is made in Bldg. 17.

Safety is My Business

Bilez Named

VFW Commander

Tony Bilez, a member of the

VFW for 22 years was named

Commander of Post 1260 in

Naugatuck. Elected officers in

the Post were Gus Hocke-

nknecht, chaplain; Charlie Con-

verse, service vice-president; and

Frank Semplesnki, junior vice

president. 100 Chemical Plant

employees belong to the VFW.

smell is very keen. Someone lit a

cigarette while we were blind-

folded and our sense of smell

really picked up the odor much

faster than under normal condi-

tions . . . but unfortunately

smell doesn’t help you see.

“In case of such an accident

happening, the program gave

some very interesting points, for

instance: feeling the warmth or

coldness of the light bulb, count-

ing the number of steps to a

doorway or stairway, most im-

portant, placing your arm across

yourself in case you bump into

something to ease your fall.

“But these helpful hints

only proved how unbearable it

must be to be blind, especially from a careless accident.

Thank God I can see! . . . I’d

hate to be blind.”

Employees (Cont’d from page 1)

rubber dust on it.

Preventing this fire requires

good housekeeping in the area;

proper maintenance and keeping

ventilation slots free from clog-

ging when doing work or in an

emergency situation. The fire was stopped as it was

small and could have been more

serious if Bianchi, Rundle, Fosdyck

and Tortoris and De Balbo had not

extinguished it so quickly.

—

## Page 004

Electrical

Power

Improved

Chemical

Control

Center

(Continued from page 1)

accurately plan the movement of

materials through their buildings. By checking the Lab data

on in-process material, the drying and grinding of off-spec

products, still in the manufacturing process, can be eliminated

and the extra cost of reworking

an off-spec product saved.

Priority System

One of the biggest hangups

in production can be mechanical

or equipment failure, but by

establishing a product priority

system, the breakdowns of

the most important products can

be kept running. Tom Downing

coordinates all mechanical activity with Clint Houstoncitect and

Leo Napello, and when necessary all required mechanical

overtime, especially if the product has a “Top” priority to meet

customer needs.

By keeping accurate records

on production and finishing, a

department is kept in close control

of its performance against its schedule, and failures or changes are

more easily made in the schedule to keep customer demands.

Accurate monitoring of raw

material receipts and monthly inventory reports have eliminated much waste and resulted in dollar

savings.

Center’s Staff

In charge of scheduling and

coordinating with the D/S department is Marty Mathewson,

with Frances Engel coordinating

the purchase of all raw materials

to insure sufficient inventory of

materials for operation of the

plant. Clark Atkinson, in charge

of the computer program for the

Center, is now mapping out a

Synthetic Kepler Retires To Alaska

“B” Crew

Hits Goal

Getting a quality tire to

the customer on time that meets

his demands in a highly competitive market is no easy job but

the Synthetic “B” crew achieved

a production goal of 8 charged

batches of latex a shift for an

entire month.

The latex market has

slumped considerably the past

twelve months due to a drop in

the carpet industry, so every

pound of latex business is

needed to keep the plant operating on a full schedule.

Efficient, steady production

of a quality Naugacyde latex is a

major step towards improvement

of our competitive position, in

keeping manufacturing costs

down, and keeping our customers satisfied.

Reaching this goal required

the full effort of all crews and in

this case, the “A” and “B”

contributed significantly to the

“B” crew’s achievement of the

month long goal.

Members of the “B” crew

are John Needham (now in the

mechanical department), Jerry

Perkins, Fred Sirmance, Fred

Miller, John Cook, Bill Boyle,

John Lawton, Horace Hermansdorfer, Toney Richard, Bob Lockwood, Earl Root, Al Karekekas,

Steve Perkins, foreman, and Fred

Engle, asst. foreman.

Computerized inventory system.

Keeping the records and statistics straight and the information

flowing smoothly is a Millie

Truell’s primary responsibility

in the Center.

The Center now completing

its first full year of operation,

has been highly successful in

helping improve production and

quality and keeping manufacturing costs down to a competitive

level, with the final result of the

Center being job security for all.

MIP Plan

(Cont’d from page 1)

purchased with the amount deducted from the payroll and the

total amount of stock that has

been purchased by the employee

to date.

Uniroyal will pay the brokerage commissions on the stock

purchased under the plan, except for any purchases made

with dividend payments.

Non salary employees can

obtain a copy of the plan and

sign-up forms from Jack Dunn;

salary employees from Alice

Egan and Kay Desceoteaux.

Safety Is My Responsibility

Phil Kepler retired after 27 years, auctioned off

his home, and set out for Alaska. Wishing him

good luck from left are Joe Viles, Alice Viles, Don

Holmes, Phil and Davie Nelson of the Synthetic

department.

High School

you must be: 1) a former member of a school class which has

graduated from high school; 2)

at least 18 years old; 3) a Connecticut resident for 6 months

just prior to the examination; 4)

out of full-time day high school

one academic year.

Subjects to Test

In the tests, emphasis is

placed on your intellectual

power rather than detail content

and on your ability to understand, evaluate, and to think

clearly. Five subject areas are

covered in the tests: Grammar,

Social Studies, Natural Science,

Literature, and Mathematics.

Exam Blows Up

Many, out of school for

several years, are overly concerned about being prepared to

take the examination. For an

individual who needs only a

“slight brushup,” several books

are available in bookstores.

Many schools have adult education courses to prepare you for

the exam.

How To Apply

An application must be

filled out in person before a

designated official in your local

school system.

The exam is given every

month (except July or August)

on the 2nd and 3rd Saturday of

the month at Waterbury State

Technical College for people in

this area.

A $5 fee is charged applicants. No fee is required for

veterans with an honorable discharge, for either the exam or

the diploma.

Employees To Take Tests

Union members passed tests

in June with high marks

after several years in the service

and a little homework.

Jesse Silva will take the test

in September. Clarence Jackson

plans to take it after a short

review of the subjects.

For further information on

how to get a high school diploma, talk to your foreman or

supervisor, or call Bill Lavelle,

Ext. 624.

PUBLISHED BY THE INDUSTRIAL RELATIONS DEPARTMENT

UNIROYAL CHEMICAL, NAUGATUCK, CONN. 06770

EDITOR: William F. Lavelle.

U.S. Postage

PAID

Permit No. 10

Naugatuck, Conn. 06770

UNIROYAL CHEMICAL

Naugatuck, Connecticut 06770

RETURN POSTAGE GUARANTEED

The startled expression is the result of Bill being told he could have a

vacation just like everybody else. He was so anxious to go, he left

this issue at the mercy of others; so, this is the result. Bill does an

outstanding job with Chem-Texts–have a restful three weeks, Bill!

Vol. 4 No. 8

Editor Lavelle Makes It

—