## Page 002

FROM THE FACTORY MANAGER

DEAR FELLOW EMPLOYEE:

I’m sure that each of us with a home and family is well aware of how increasingly difficult it is to maintain the standard of living to which we are accustomed, in light of higher overall costs of products and services.

Each month we are faced with regular bills for rent or mortgage; food, fuel, telephone, electricity, gasoline, as well as emergency ones for the doctor, dentist, or automobile repairs. As these costs rise, we do our best to control them by avoiding wasteful use of electricity and water and, in general, by the careful spending of our dollars.

We, at the plant, are faced with similar problems. This year our fuel bill will increase over $600,000; and the cost of electricity will increase $33,000.

We will also have a bill similar to an emergency one for the doctor, of approximately $3,000,000 for the waste water treatment plant.

It will take the fullest cooperation of all employees in order to control and reduce these costs. We must strive to operate in a more efficient manner; prevent accidents and serious injuries; obtain more efficient quality production; avoid waste and off-specification material; and to make suggestions to improve the plant’s overall efficiency.

If each of us gives our time, knowledge, skills and ideas to our fullest capabilities. I’m sure that we will be able to maintain and improve the position of our plant in terms of employment and income.

NOW STUDENTS TOUR LAB.

[Image of students touring a lab facility]

Young high school students from the North End Opportunity Center in Waterbury saw demonstrations in action during a visit of the Research facilities in Bldg. 81, as part of a Boy Scout project to earn their Chemistry Merit Badge. With saved attention and enthusiasm the young chemists watched Dr. Byron Hunter perform miracles with chemical reactions that expanded rubber to twice its normal size. “They asked some sharp questions,” Dr. Hunter commented.

In the Analytical Control Lab, Anna Radovich demonstrated instruments and methods used to analyze products manufactured in the plant for quality to assure the customer.

Anna Radowich shows a group a sample of liquid asphalt. (AI. McBoski photo.)

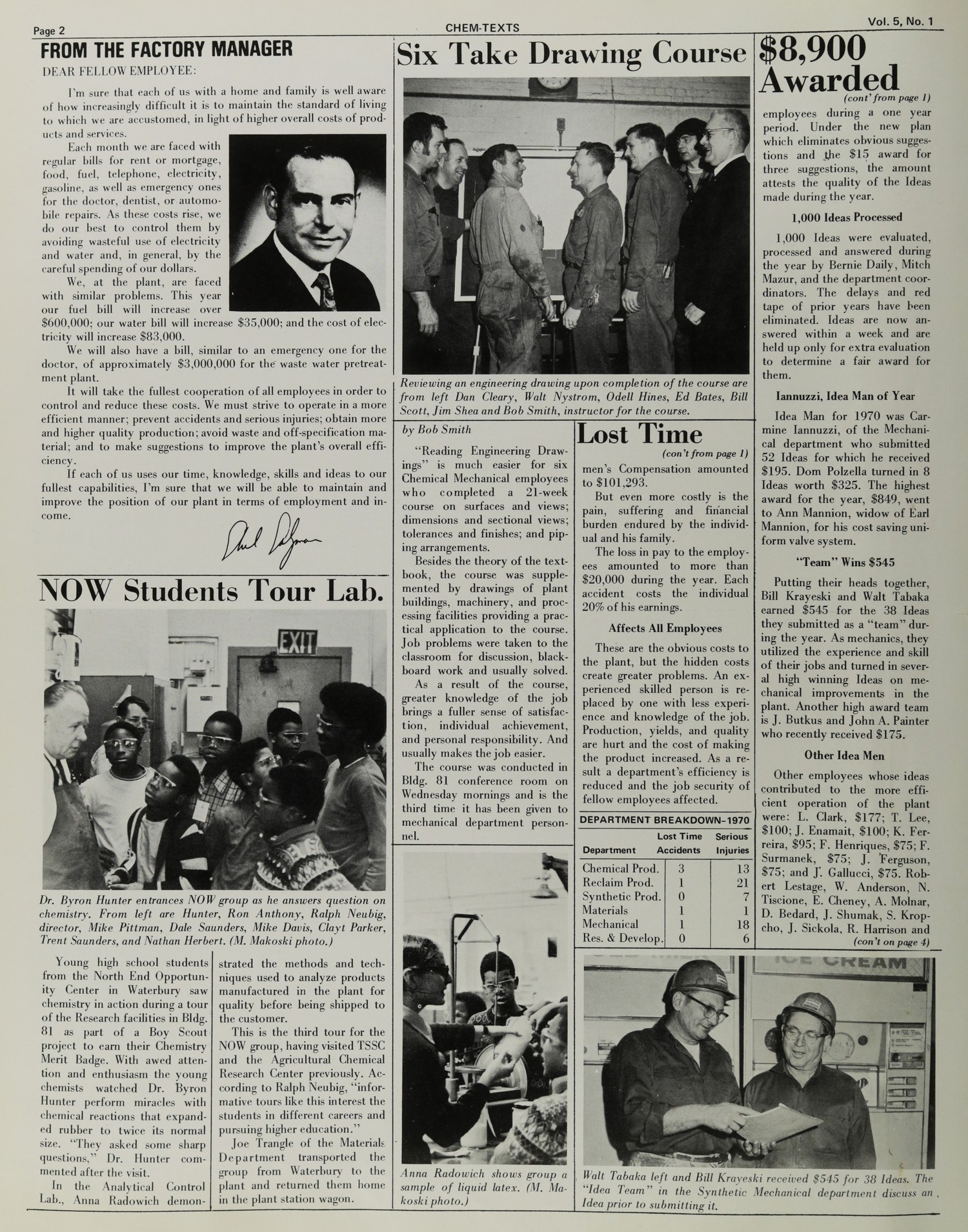

SIX TAKE DRAWING COURSE

Reviewing an engineering drawing upon completion of the course are from left Dan Cleary, Walt Nystrom, Odell Lines, Ed Bates, Bill Stahl, Jim Shona and Bob Wartha, instructors.

Lost Time

“Reading Engineering Drawings” is the much easier said than done course for Chemical and Mechanical employees who completed a 21-week course on surfaces and views; dimensions and sections; tolerances and finishes; and piping arrangements.

Besides the theory of the textbook, the course was supplemented by drawings of plant buildings, machinery, and processing facilities providing a practical application to the course.

Job problems were taken to the classroom for discussion, blackboard work and usually solved.

As a result of the course, greater knowledge of the job brings a fuller sense of satisfaction, individual achievement, and personal responsibility. And usually makes the job easier.

Bill Kreyeski, who conducts the Wednesday morning class, says the third time it is given, the mechanical department personnel did extremely well.

$8,900 AWARDED

(cont’d from page 1)

employees during a one year period. Under the new plan

which eliminates obvious suggestions and the $15 award for

three suggestions, the amount attests the quality of the ideas

made during the year.

1,000 Ideas were evaluated, processed and answered during

the year by Bernie Daily, Mich Mazur, and the department coordinators. The delays and red tape of prior years have been eliminated. Ideas are now answered within a week and are held up only for extra evaluation and calculation to determine a fair award for them.

Ianuzzi, Idea Man of Year

Idea Man for 1970 was Carmine Ianuzzi, of the Mechanical department who submitted 52 Ideas for which he received $195. The highest award for the year, $849, went to Ann Manning, widow of Earl Manning, for her cost-saving uniform valve system.

“Team” Wins $545

Putting their heads together,

Bill Krayeski and Walt Talaska

earned $545 for the 38 ideas

they submitted as a “team” during the year. As mechanics, they utilized the experience and skill

of their jobs and turned in several high winning Ideas on mechanical improvements in the

plant. Another high award team

is J. Butkus and John A. Patnter

who recently received $175.

Other Idea Men

Other employees whose ideas

contributed to the more efficient operation of the plant

were: L. Clark, $177; T. Lee,

$100; J. Emanuel, $100; K. Ferrara, $95; F. Henriques, $75; F.

Surmanek, $75; J. Ferguson,

$75; and J. Gallacci, $75. Roberta Carlston, W. Anderson, N.

Tisclone, E. Cheney, A. Molnar,

D. Bedard, J. Shimovic, S. Tagliareni, J. Sikora, H. Harrison and

(cont’d on page 4)

DEPARTMENT BREAKDOWN-1970

Lost Time Serious

Department Accidents Injuries

Chemical Prod. 3 13

Reclaim Prod. 1 21

Synthetic Prod. 0 1

Materials 1 18

Mechanical 1 6

Bldg. & Develop. 0 6

Walt Talaska left and Bill Krayeski received $545 for 38 Ideas. The

“Team” won the Synthetic Mechanical Department contest on an

Idea prior to submitting it.

—

## Page 003

Here is the extracted text from the document image, preserving the layout and structure as much as possible:

New Duster Cleans Air $20,050 Pledged To United Givers

Reviewing the final results of the United Givers drive which resulted in pledges of $20,050 from 965 employees are seated from left: Joe Rozeski, Sam Gillette, chairman, and Dick Edwards. From left standing are Mill Makoski, Bob Van Allen, and Roger Amidon.

Scholarship Offered

by Lou Kaiser

The Universal Chemical Management Club is again offering a $250 scholarship, which is available to a son or daughter of a Chemical division employee with two or more years of service.

The scholarship is open to students in the graduating class of a high school or preparatory school who plan a college education. Application can be obtained from the Industrial Relations department.

This year the scholarship will again be augmented by a $50 cash endowment from Larry Monroe, a retired Chemical division employee.

Joe Boccaglio is Chairman of the Scholarship committee and all applications must be mailed or returned to him on or before April 1, 1971.

Plumes Not Pollutants

On clear cold days the white plumes from the plant’s production operations are more prominent. Most of the “white stuff” is harmless water vapor resulting from the condensation of steam after it has performed its necessary function in providing the heat for the buildings.

Ed Leiner applies tale to bale of Naugatoll rubber as Ed Curly watches. Equipment, recently installed, eliminates the dust in the area and provides protection to employees’ health, according to Lou Kaiser.

The production of various types of Naugatoll rubber re-quires tale to be applied to the rubber bale before it is packaged. To eliminate the dust problem, a tale station was redesigned and a larger hood was installed to provide greater air flow across the tale station. The dust laden air then lead to a cyclone where it is collected and clean air returns to the atmosphere.

With the improved ventilation, it is no longer required to wear a mask when the tale is applied to the rubber. However, it was decided that an improved mask was still applied to the rubber.

Hoist Taken From TSSC

A quarter-ton electric hoist valued at $500 was recently taken from the Plastics Compounding Lab in TSSC (Bldg. 112). The hoist, attached to an overhead rail, required a ladder and two men to remove.

Thefts of electric drills, wrenches and small tools have also been reported in the same building.

Besides the extra cost to the plant, the thefts cast suspicion on all employees in the building, and new rules are effected to restrict their actions because of the individual’s actions.

The loss imposes harder work conditions on the men who now have to use a hoist from another section of the building.

DO PEOPLE REALLY UNDERSTAND YOU?

On clear cold days the white plumes from the plant are more prominent. Most of the “white stuff” is harmless water vapor resulting from the condensation of steam after it has performed its necessary function in providing the heat for the buildings.

“Let the man with two coats give to him who has none; the man who has food should do the same.”

Generous concern for people by Universal Chemical employees was again shown with a pledge of $20,050 to the United Givers which benefits the physically handicapped, mentally retarded, broken homes, the young and the old in the communities around us.

The amount represents one-sixth of the total pledges for the Naugatuck-Beacon Falls 1971 Drive. 965 out of 1,500 employees contributed with 662 using the payroll deduction plan.

The highest pledges were $240: $225: $105: with several in the $120 range.

Department Pledges

EMC pledged $4,140 for the highest department contributions last year’s goal was $1,000. Several departments dropped below their contributions of 1970 which accounted for attaining only 93% of the $22,000 plant goal.

1971 Amount

Dept. Pledged Dept. Pledged

Chem. Prod… . 3,325 3,707

Syn. Prod. . . . 2,200 2,151

Engr. . . . . . . 1,700 1,801

Lab., & Mech.

Chem. . . . . . . 1,550 1,350

Traffic . . . . .1,100 803

Sales . . . . . . 1,450 1,209

Factors Service. 1,400 1,209

Rec & Develop . 5,000 5,530

Accounting . . . 900 363

EMC. . . . . . . 3,100 4,410

Sam Gillette was Chairman of the drive with Dick Edwards, Roger Amidon, Joe Raskauskas, Jack Vergosen, Bob Van Allen, Eric Johnson, Don Pesaratti, Mill Makoski and Bill Lavelle serving on the executive committee for the drive.

Chairmen organizing the campaign in plant departments were Vic Alves, Frank Lynch, Bill Lundhart, Ernest Krause, Clark Makison, Jack Prior, Colin Walker, Julius Reb, Benis Zukaitis, Walt Miller, John Davidson, Rod Lanius, Paul Murray, Bob Dexter, Larry Gallurn, Dan Shaughnessy, Stan Mann, Carl Byers, Gene Peagles, and Alex Zonas.

Finance records for the campaign were kept by Ed Levanduskas of the Accounting Department.

You can protect your heart and health. Flu vaccines, by having a small routine of daily exercise and by proper diet, especially avoiding being over-weight.

FREE X-RAY MARCH 25 PROTECT YOUR HEALTH

—

## Page 004

Four Employees Retire

X-Ray Unit Group Tutors Young

Visits Plant

by Bob Shortt

On Thursday, March 25, a

mobile X-ray unit will visit the

plant for chest X-rays of all employees. This service is free and is

part of an improved medical service program for employees recommended by Dr. Edward Jelley, plant physician.

The unit will be open from 6

A.M. until 6 P.M. and can X-ray

125 people an hour.

Employees will be provided a

form to complete prior to the

visit. Results of the X-ray will be

returned to Dr. Jelley, who will

file it in the employee’s medical

record.

Details are posted on departmental bulletin boards.

Fuel Costs

Save Steam Program

The program to save steam

will concentrate on giving maintenance priorities to steam leaks,

faulty steam traps, valves, heaters, controls and broken insulation. A large amount of heat loss

is caused by open doors and

windows which are also a major

factor in frozen pipelines and

damage to equipment.

10-20% Of Steam Lost

It is estimated that 10-20% of

the steam produced is being wasted through leaks, open doors, and

windows, or by excessive use.

$35,000 is spent a month

for an average of 18,000 lbs.

of steam, and for a

total yearly cost of $8,000.

CHIF Offers

(con’t from page 3)

limit to be eligible for CHIF assistance.

It must be a minority employee, or one who believes to be,

and who is actively participating.

The services of CHIF

are primarily involved in assisting members of minority groups

in the purchase of their own

homes.

If you are interested in obtaining more information about

CHIF, call Bill Makoski, Industrial Relations Department, Ext.

217, or contact CHIF directly in

the Steel Building, 51 West Main

Street, Waterbury – phone

754-1071.

Safety

(con’t from page 1)

son has been instructed to require all employees to wear new

hardhats in designated areas in

the plant.

Part of the recommendation

will be the wearing of hard hats

and safety glasses throughout

areas of the plant as designated

on maps to be distributed to all

employees.

Program Timetable Set

The following timetable has

been set for the hard hat and

“No School Today” was John

McCarthy’s philosophy. Wishing

him good luck after 21 years as a

millwright are from left Mary

O’Brien, McCarthy, Bill Rock, who

shared his beard, and Jim Norton.

Helping Rose Deardsley cut a

cake on her retirement after 24

years service in Accounting are

left to right Earl Mooney, Larry

Montembault, Rose Deardsley.

$8,900

Awarded

(con’t from page 2)

J. Chase received $500 each. A

$25 award went to A. Cross and

a $30 award to J. Ardahaskas.

$25 was given to J. Ramos, J.

Hanley, H. Needham, O. Grabinski, J. Martino, Jr., J. Shalrnan,

A. Gaffney, J. Lawton, J. Kazemkas, S. Diebilis, H. Hernandez, M. Rosa, I. Ritchie, F.

Simonds, K. Nelson, E. Casey, N.

Owens, S. Mazarski, R. Lockwood, L. Raskauskis, J. Iori, G.

Monahan and F. Kasheimer.

A $15 award went to R.

Jennings, a carryover from the

old Suggestion System.

Thirty-two employees received

letters of Commendation: P.

Blako, J. Jakabaska, J. Morris,

L. Marl, J. Dobrindt, F. Phillips,

J. Brown, G. Perkins, E. Ates,

F. Miller, A. Hapey, J. Napello,

D. Menillo, R. Guest, A. Gedrites, L. Roocha, A. Gridello, C.

Stefflo. J. Sullivan, F. Bender,

W. Lavelle, C. Moniska, C. Zawacki, J. F. Brown, E. St. John,

J. Owens, J. Salitorski, J. DeSilva, F. Surmanek, W. Parks,

and J. Musho.

SAFETY IS MY RESPONSIBILITY

Dr. Frank O’Shea and Sister Irene of the Sisters of Charity greet the

two pretty Carron sisters, Maribel and Myra as they arrive for a onehour busy session. Not in the photo is Sister Margaret Sprague, who

was busy involved in organizing the session.

Leach, a vice principal of the

Forty-eight Uniroyal Chemical employees tutor young high

Bernard School. In this group,

school students from the Waterwhich meets Mondays and Tuesford Parochial School. They are

days at the Woodrow Wilson

R. Bay Allen, Steve

R. Alger, Bill Brodin, Joe Buczak,

School, are

Bob Cassarino, Lou Costa,

ing, Bob Cassarino,

Bob Flores, Jim Gulling, John

Gilbert, Paul Hinckley, Keith

Hughes, Russell Mazur, Jr., Dr.

Bob Niedermeyer, Fred Sheclov,

Sandra Wearing, Dr. Roger Anderson, Sandra Bond, Dr. Jim

Brown, Jr., Dr. Bob Broun, Dr.

Breaults, Dave DaVia, Brendan

Kerrins, Dr. Van Land, Clark

Kellison, John O’Donnell, Evere

Perkins, and Dan Shantz.

The tutors are

Mike Jusman, Lindo McDonald,

Ernest Lussier, Bob Lombardi,

Bob Swallow, Ed Dunn, Neil

Moore and Peter Bosnyak.

Go Greco volunteers for service.

CHEM-TEXTS

PUBLISHED BY THE INDUSTRIAL RELATIONS DEPARTMENT

UNIROYAL CHEMICAL, NAUGATUCK, CONN. 06770

EDITOR: William F. Lavelle.

U.S. Postage

PAID

Permit No. 15

Naugatuck, Conn. 06770

RETURN POSTAGE GUARANTEED

safety glasses throughout

areas of the plant as designated

on maps to be distributed to all

employees.

UNIROYAL CHEMICAL

Naugatuck, Connecticut 06770

Employee’s Safety

The basic purpose of the new

program is to protect employees against accidents and serious

injuries. Since 1967, seventy-one

employees suffered lost-time accidents and 246 had serious injuries.

With every employee’s cooperation, this new program will

help prevent the occurrence of

accidents and make the Naugatuck plant a safer and better

place to work.

SAFETY IS MY RESPONSIBILITY

—

## Page 183

CHEM-TEXTS

Vol. 5, 1971 PUBLISHED FOR THE PEOPLE OF UNIROYAL CHEMICAL No. 1

$8,900 Awarded For Ideas

Fuel Costs Safety

Doubled Equipments Program

For 1971

Save Steam Plan

Started In Plant

by Al Matza

Total fuel costs for 1971 will

be approximately double over

1970. $555,000 has been

budgeted to operate the plant

during the year against actual

costs of $638,000 for last year.

The $555,000 increased cost

of fuel is primarily due to escalation residual oil prices which

are a result of the Mid-East

crisis, rather shortages and pol-

lution abatement conversions to

oil. As added cost is the pre-

mium we will pay for low sulfur

oil after Sept. 1, 1971.

Profits Off

$4,100,000

Uniroyal showed a $4,100,000

loss for the 4th quarter of 1970

compared to a profit of

$8,400,000 in 1969.

Sales for the same quarter

were $371,000,000, a decrease

of $17,000,000 from the same

period last year.

1970 sales of the company

were $1.551 billion, almost the

exact amount as the prior year.

Earnings in 1970 were only

$23,800,000 compared to a net

income of $46,600,000 in the

year of 1969.

The decrease in 1970 profits

was said to be attributed to the

GM strike, the general softness

in the economy, high interest

charges, sharply higher employ-

ment costs, higher transporta-

tion charges and other costs not

fully absorbed by price increases

or productivity improvements.

Plant Business Down

During the year production of

reclaimed rubber, lates and rub-

ber chemicals was affected by

the dislocation in the automotive

industry, home construction and

the shutdown of several Uni-

royal tire plants.

The plant’s business shows

scarcely any improvement

according to the present sales fore-

casts for the first quarter of

1971.

Every effort needs to be made

at this critical time in our econ-

omy to prevent off grade pro-

duction, improve productivity

and quality, and to keep cus-

tomers satisfied.

Dividend Declared

Uniroyal declared a quarterly

dividend of 17¢ cents a share on

the company’s common stock.

The dividend is payable March

25 to shareholders of record on

Feb. 24.

The Company also declared

a quarterly dividend of 32¢ each on

Uniroyal’s preferred stock. One

will be paid March 20 to stock-

holders of record February 22,

and the other payable June 22

to stockholders of record

May 24.

Lost Time

Accidents

Drop To 6

By Sol Morse

The incidence of lost time

accidents showed a major im-

provement in 1970. The plant

had only 6 compared to the 23

in 1969. Two of the accidents

occurred in an odd

situation.

An employee fell on ice and

fractured two ribs. A few days

later he visited Dr. Jelley at the

Chemical plant hospital prior to

his return to work. After his

checkup, Tom Doran, a plant

driver, drove him home. When

Doran stopped for a stop sign, a

trailer truck skidded into the

station wagon, injuring Doran

who suffered a severe neck

strain. One of the safest, most

experienced drivers in the plant,

Tom lost a month of work when

the “unexpected” happened.

Accidents Cost $150,507

The 6 lost time accidents and

66 serious injuries cost the plant

$150,507 in 1970. The outside

medical bills for hospitalization,

X-rays, specialists, medicines and

doctors’ visits were $49,214.

The money paid out for Work-

(con’t on page 2)

Elephant Tests Chair

Elsie, a 5,000 pound elephant,

torture tests a molded urethane

plastic chair made by a new

process developed by Rohcon

Chemical Company and owned

by Uniroyal Chemical and Imperi-

al Chemical Indus-

tries, Ltd. The liquid urethane

chemicals were poured into special

chair molds and react into a rigid

foam to create furniture that has

fantastic strength, is lightweight

and easily movable. The chairs

are then filled with flexible foams

for deep seating comfort and

upholstered with “Naugahyde”

vinyl.

Research work on the new

process was done in Bldg. 75 by

John Haggerty, Group Leader,

John Chapman, Don Zalewa-

ski, Ken Ferriere and Jim McGinn.

Al Urban, center, a fixture operator in Reclaim Production, receives

a $50 Award for his suggestion to the Safety Profit Program. At right,

Art Neugass, area foreman, recommended the safety ideas, previously

discussed, and is all in favor of such incentive plans.

Lost Time

Accidents

Drop To 6

(con’t from page 1)

men’s Compensation and other

costs and scrap haulag e charges.

It took six months to evaluate

the idea for which Urban re-

ceived an initial award of $50

and a subsequent award of $426.

The $8,900 was one of the

highest amounts ever awarded to

(con’t on page 2)

257 employees received

$8,900 for ideas in 1970. A higher

award of $426 was made to Al

Urban for his idea to reuse bayl

tuber heads which were previ-

ously discarded after short use.

The bayl is now reclaimed; fin-

ished; and sold, saving materials

cost and scrap haulag e charges.

It took six months to evaluate

the idea for which Urban re-

ceived an initial award of $50

and a subsequent award of $426.

The $8,900 was one of the

highest amounts ever awarded to

—