## Page 002

Here is the text extracted from the document image:

FROM THE FACTORY MANAGER

DEAR FELLOW EMPLOYEE:

The National Safety Council recently presented an Award of Merit to the Naughtuck Chemical plant in recognition of its notable safety achievement in 1970. The Award was based on the significant drop in our lost-time accident experience during the year: only 6 compared to 24 for each of the three previous years.

In helping to attain this performance, everyone in the plant deserves to be congratulated. Such an achievement is the result not only of individual effort and cooperation. With everyone’s increasing concern for safety and with the plant manager’s heightened emphasis on this aspect of our operations, we were able to realize a dramatic improvement in our safety experience.

During the past year, five employees were involved in near-serious eye accidents that would certainly have resulted in damage to their sight. Fortunately, all were wearing their safety glasses at the time of the accidents.

Although our on-the-job safety performance has improved, let’s not overlook safety when away from the job.

Off-the-job safety becomes especially important as the warm weather and vacation time approaches.

At this time there’s a tendency to take extra risks in working around the house–using lawnmowers, climbing ladders, or lifting heavy objects.

On vacation, there’s the urge to do everything fast–driving carelessly, exceeding the speed limit in sports cars.

Whether at work, at home, or on vacation–let’s continue to place a great deal of emphasis on good safety habits. Not only you, but your family and fellow employees will benefit from it.

Nystrom Gets $300 Grant

Harvey Nystrom receives Scholarship Award from Lee Bucciglia. From left are Bob Kaiser, Walt Nystrom, Harvey Nystrom, Bucciglia, and Harvey J. Nystrom, son of Walt Nystrom, a Millwright in the Chemical Mechanical Department. He received a Certificate from the Chemical Management Club’s $250 scholarship award, along with an additional $50 from the Larry Monroe Fund. Ranked first among 172 seniors at Southbury High School, Nystrom was selected as recipient of the Scholarship from 15 applicants. According to Joe Bucciglia, Chairman of the Scholarship Committee, “all of this year’s applicants were deserving of the scholarship. It was most difficult for the committee to select one person.”

Logic-Networks Plan Initiated For Liquid Waste Pretreatment Plant

To construct the new $3,000,000 Liquid Waste Pretreatment Plant on schedule, a coordinated, scientific plan for the complete pollution abatement project was initiated to achieve the target completion date in December, 1972. This major project involves a coordinated effort by many groups to identify the sources of pollution; to eliminate and reduce pollution; and to construct and put into actual operation the Waste Pretreatment Plant.

Logic-Networks Used

The Logic-Networks system is being used to plan, coordinate, and monitor and control the pollution abatement project. It is an easy-to-understand, graphical

$1,564 Lost

In GMF Fire

$1,564 was lost in a fire which occurred in the GMF grinding section of Bldg. 101. While grinding the chemical, used as an accelerator for curing butyl rubber, a flash fire broke out. The GMF operator on the second shift pulled the fire alarm and the heat from the fire turned on the overhead sprinkler system.

Quick action by the fire inspectors and chemical production operators prevented more serious damage. Because of GMF were destroyed, but a loss of over $500, mechanical and electrical equipment damage included more than $1,000 for clean-up and repair.

The fire was the first in the plant history which amounted to serious damage. The exact term of this loss is still undetermined.

Club Elects New Officers

New officers of the Uniroyal Chemical Management Club and the Executive Committee meet to plan activities for the year. Seated from left are Dan Simitis, Lou Azzero, president; Bill Boudin, vice president; and Doug Ritchie. Standing from left are Bob Smith, treasurer; Karl Roller, Stan Marui, Dick Kreman, secretary; and Bob Grum.

Logic-Networks Plan Initiated For Liquid Waste Pretreatment Plant

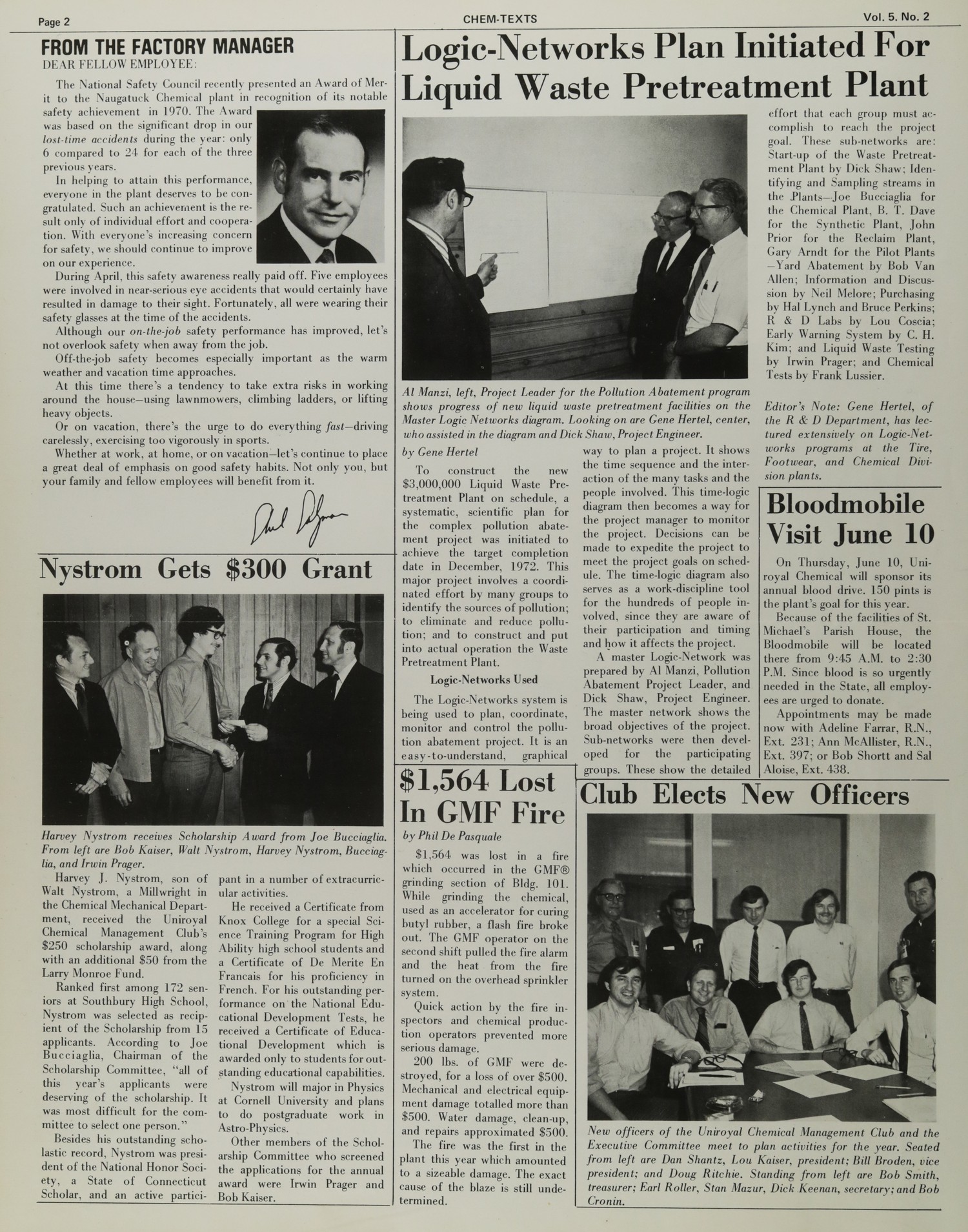

At left, Project Leader for the Pollution Abatement program shows sections of the new liquid waste pretreatment facilities on the Master Logic-Networks diagram. Looking on are Gene Hertel, center, the R & D Department, who has featured extensively on Logic-Networks programs at the Tire, Footwear, and Chemical Division plants.

To construct the new $3,000,000 Liquid Waste Pretreatment Plant on schedule, a coordinated, scientific plan for the complete pollution abatement project was initiated to achieve the target completion date in December, 1972. This major project involves a coordinated effort by many groups to identify the sources of pollution; to eliminate and reduce pollution; and to construct and put into actual operation the Waste Pretreatment Plant.

The Logic-Networks system is being used to plan, coordinate, and monitor and control the pollution abatement project. It is an easy-to-understand, graphical $1,564 Lost In GMF Fire

$1,564 was lost in a fire which occurred in the GMF grinding section of Bldg. 101. While grinding the chemical, used as an accelerator for curing butyl rubber, a flash fire broke out. The GMF operator on the second shift pulled the fire alarm and the heat from the fire turned on the overhead sprinkler system.

Quick action by the fire inspectors and chemical production operators prevented more serious damage. Because of GMF were destroyed, but a loss of over $500, mechanical and electrical equipment damage included more than $1,000 for clean-up and repair.

The fire was the first in the plant history which amounted to serious damage. The exact term of this loss is still undetermined.

Club Elects New Officers

New officers of the Uniroyal Chemical Management Club and the Executive Committee meet to plan activities for the year. Seated from left are Dan Simitis, Lou Azzero, president; Bill Boudin, vice president; and Doug Ritchie. Standing from left are Bob Smith, treasurer; Karl Roller, Stan Marui, Dick Kreman, secretary; and Bob Grum.

Editor’s Note: Gene Hertel, of the R & D Department, has featured extensively on Logic-Networks programs at the Tire, Footwear, and Chemical Division plants.

Bloodmobile Visit June 10

On Thursday, June 10, Uniroyal Chemical will sponsor its annual blood drive. 150 pints is the plant’s goal for this year. Because of the facilities of St. Michael’s Parish House, the Bloodmobile will be located there from 9:45 A.M. to 2:30 P.M. Since blood is so urgently needed in the State, all employees are urged to donate.

Appointments may be made now with Adeline Farrar, R.N., Ext. 231; Jan McAllister, R.N., Ext. 397; or Bob Short and Sal Aloise, Ext. 438.

—

## Page 003

Here is the text extracted from the document image, preserving the layout and structure as much as possible:

Safety Glasses Save Eyesight of Five Employees

Set Goals; Show Results

The Management By Objective program at the Chemical plant uses results as the major measurement criterion. The purpose of the program is to provide the challenge of individual responsibility; a sense of accomplishment; and personal involvement in the successful operation of the plant during the year.

In the program supervisory personnel and members of their departments mutually define specific goals, individual areas of responsibility, and the results that can be expected on the job.

The objectives for each department must fit into the overall objectives of the plant so that each group in the plant works as a unity toward the plant’s and Company’s objectives.

Emphasizes Results

Results, rather than activity, is the measurement by which each person is appraised. Since the individual helps set his own goals, he is accountable for his own achievements.

To be measurable, the objectives are set up as specific as possible in dollars, amounts, times, percentages, quality and other categories.

Four standards are used in the measurement guide which are reviewed quarterly and revised, or new standards and targets set as necessary: 1) Result Areas; 2) Objectives; 3) Commitments; and 4) Supervisory Action.

When properly carried out the program provides the individual the incentive to achieve results.

Savings Bond Drive Starts

On May 25 a U.S. Savings Bond drive was initiated in the plant to offer all employees an opportunity to purchase Savings Bonds.

In view of the new higher interest rate of 5 1/2%, more people are taking a new look at Savings Bonds as a safe, systematic investment.

For convenience, the Bonds can be purchased by regular payroll deductions.

Presently 35% of the plant’s employees are buying U.S. Savings Bonds through the Payroll Savings Plan.

Application forms for enrollment can be obtained from the Bond Drive Committee members, Foremen, Supervisors or from Gladys Bradshaw, Industrial Relations Department, ext. 517.

Completed forms should be returned to W. Lowdle, Industrial Relations Department.

Don’t drive after taking certain pills, such as tranquilizers or antihistamines. They may have side effects that affect judgment, cause dizziness, sleepiness, and confusion.

Safety is My Responsibility

Safety Award Received

An Award of Merit was presented to the Naugatuck Chemical plant for the “Outstanding safety performance” in 1970. The plant’s lost time accidents dropped from 24 to 6 days during this period.

Tony Galletta shows Gene Regan how a chipped punctured paint can exploded in his face.

Without warning, the reaction vessel exploded, and covered the entire room with glass.

A glass stopper shattered the right lens of safety glasses.

Glasses were covered with metallic particles from punctured can.

Instrument light fixtures were broken and the entire laboratory area was covered with glass particles.

“It is almost certain that both of us would have suffered severe eye damage or possible loss of sight without our safety glasses,” A few days prior to the accident, Dr. Tom Brett had held a 5-gallon safety meeting emphasizing the use of sodium HBP. A small amount of the chemical in the bottom of the drum splashed

Fashions In The Plant

Paris, Rome, or London may be the fashion centers of the world but the Naugatuck plant has some style fashions of its own.

Modeling the styles from left to right are Ann McAllister R.N., Marge Mayo, Steve Hawlickie, Doug Klima, Cynthia Martino, and Sandy Bond.

—

## Page 004

Here is the extracted text from the document image:

CHEM-TEXTS Vol. 5, No. 2

Know Your Products:

Rubber Chemical Accelerators

by Dr. Bob Brown

Virtually every tire on the road today contains one of the chemicals made by the Chemical Division to protect them against oxygen, ozone, heat, fatigue and sunlight. Without these chemicals the rubber would deteriorate rapidly.

Coincidentally, it was one of our rubber chemicals that established us in the agricultural chemical business when it was discovered that the chemical had fungicidal properties. Twenty-five years later, the Division ranks as a major manufacturer of herbicides, growth regulants, miticides and fungicides.

The chemicals that we make at Naugatuck for the rubber industry do a wide variety of jobs; but two are by far the most important. These are: 1) Accelerators for vulcanization and 2) Antioxidants and Antiozonants for protection against aging. A third group – others – include Blowing Agents for rubber and latex sponge; bonding rubber to fabric, metal and plastic.

Safety Glasses

(cont’d. from page 1)

in his face and would have injured his eyes if he had not been wearing his safety glasses. Tony DeSalva, an operator in Chemical Production, was sprayed with sodium MBT when a plugged line broke. The chemical covered his face, arms and chest. His safety glasses averted serious injury to his eyes.

During the first four months of the year, 57 eye injuries took place. Fortunately most employees were wearing safety glasses at the time of the accidents, preventing serious damage to their eyes.

Profits

(cont’d. from page 1)

quarter. But replacement tires

lagged behind the same period

last year. Replacement sales are

expected to improve sharply

during the year.

The Footwear business also

showed progress during the first

quarter.

Chemical Sales Down

“A major trouble spot at the

present time,” according to Mr.

Vila, President and Chairman of

the Board of Directors, “is in

our domestic chemical operations where severe price erosion

in many product lines has resulted in a sharp drop in earnings.

This has been caused, in part, by

competition from foreign

sources, in part by the expiration of certain patents and, in

part, by a drop in demand for

chemical products generally.”

A Worldwide Competitive

Manufacturing Complex

The heavy capital investment

made by the Company in recent

years now gives it a worldwide

manufacturing complex which,

for the most part, is modern and

fully comparable with competition.

Present manufacturing facilities are sufficient to give the

Company sales of about $2.50 billion, an increase of approximately 20% over present sales levels.

This processing has to be done

at a high temperature to make

the rubber soft enough to handle, and there is always the danger that it will start to vulcanize

before it is finished. For this reason, chemicals want the accelerators that have some “delayed

action”. MBT has a little delayed

action; MBS has more; and

DELAC’S has the most.

(To be continued in the next issue of CHEM-TEXTS.)

Hats, Glasses

URW Master Agreement which

emphasizes a cooperative effort

to prevent accidents among employees and to utilize the proper

protective equipment as prescribed by local management.

$150,507 Lost in 1970

In 1970 there were 69 lost time

accidents and 65 serious injuries.

The cost of medical bills and

Workmen’s Compensation for

the year totaled $150,507, an

amount equivalent to $100 per

employee.

225 employees suffered eye

and head injuries in the same

year. Of these, 170 were eye injuries and 53 were head injuries.

For your personal safety and

your fellow employees, and for

your family’s sake, make sure

your safety glasses and hard hats on

the job are not lost, it can never be replaced.

Phase I

(cont’d. from page 1)

ent materials, which results in a

complex waste mixture, difficult

to adequately treat.

As State environmental laws

and regulations become more

strict, it will be essential to control and contain the flow of materials into the plant drains.

$4,000,000 Spent. Committee

The new facilities, including

the financial commitment to the

Borough and the action model product

test, will cost

$4,000,000, exclusive of the operating costs.

Little of the costs expended

to date have been absorbed by

increased product prices to customers. These costs have been

mainly by the plant.

The completion of the facilities is scheduled for December

1972 in compliance with orders

from the State Water Resources

Commission.

Six Retire Recently

John Hickson, (third left), retired from Reckam after 25 years service.

Congratulating him are from left: Pablo Guzman, Lee Thompson,

Hickson and Bernie Dann.

Bruno Rossi, left, and George Pohorylak with each other a happy

retirement as Mrs. Makowski, center, watches. Bruno had 39 years

service, George, 30 years.

While Fortier, center, retiring after 26 years, receives gift from fellow

employees. From left: Tony Galietta, Gene Reale, Fortier, Sol pal

Caccaro and Lou Marottolo.

Retiring after 40 years service Andy Smey, center, is congratulated

by Harry Witt, and Joe Johnson.

Congratulating John Quint on his retirement after 29 years service

are from left: Joe Alee, John Pointer, Quint, Tim Carr and Ted

Dematteo of the Synthetic Mechanical department.

PUBLISHED BY THE INDUSTRIAL RELATIONS DEPARTMENT

UNIROYAL CHEMICAL, NAUGATUCK, CONN. 06770

EDITOR: William F. Lavelle.

U.S Postage

PAID

Naugatuck, Conn. 06770

RETURN POSTAGE GUARANTEED

—