## Page 002

FROM THE FACTORY MANAGER

DEAR FELLOW EMPLOYEE:

The miracle of the U.S. economy’s continued growth in the post-World War II is something all Americans can be proud of. Much of it can be attributed to the technological leadership of U.S. industry and to the productivity of the American workers. Our standard of living in this country is better than any people in history.

This miracle didn’t just happen. It was brought about by the tremendous productivity of the people of this country. For twenty years every time wages increased, productivity also increased and our standard of living went up.

In the last five years, however, we have seen a change in this pattern. While wages have increased, productivity has not kept pace with them. This has helped cause inflation and has helped drive the cost of our products up.

In turn, foreign manufacturers have maintained their productivity and are now able to sell their goods in our markets at prices lower than ours. We can see this in Japanese electronics, German and Japanese automobiles, and textile and footwear products from all over the world.

On a smaller scale the same thing is happening at our factory.

We are in competition with both foreign and domestic producers. They are competing with us for the same customers, the same markets, oftentimes at lower prices. Besides this our markets are moving away from the northeast and the increasing cost of fuel and truck transportation add to our problem of doing business competitively.

All of us must realize this and remember that the chemicals we produce are in competition with these domestic and foreign manufacturers. We can only sell what we can produce economically. We can only produce economically with your help and cooperation.

Every job in the plant is important. Every person counts in this effort. We all must chip in.

Plant Joins JOBS ’70

By Milt Makosk1

The Chemical plant recently joined the JOBS ’70 consortium organized by the Greater Waterbury Chamber of Commerce. The consortium, or group of businesses, has 15 member in-dustries and a goal of 180 job slots to be filled this year. The Chamber organized the group under a grant from the National Alliance of Businessmen and the Federal Department of Labor.

The JOBS program is aimed at training poor people for meaningful employment. The trainees are given work orientation, counseling, total wage development, job related education and on-the-job training.

The program participants are grouped into clusters according to the type of training to be received. One cluster of 15 girls, who learned to be clerk-typists and transcriptionists, have already been placed in Uniroyal facilities. Four of the girls are now working at the Chemical plant, and 11 are at the Oxford Administrative and Research Center.

In charge of the Chamber’s portion of the program is Gus Makosky. The Chemical plant, representative with JOBS ’70 is Milt Makoski and the Uniroyal Corporate representative, Rita Garamone.

33 Employees Receive $1355

Mechanical Department Submits Most Ideas

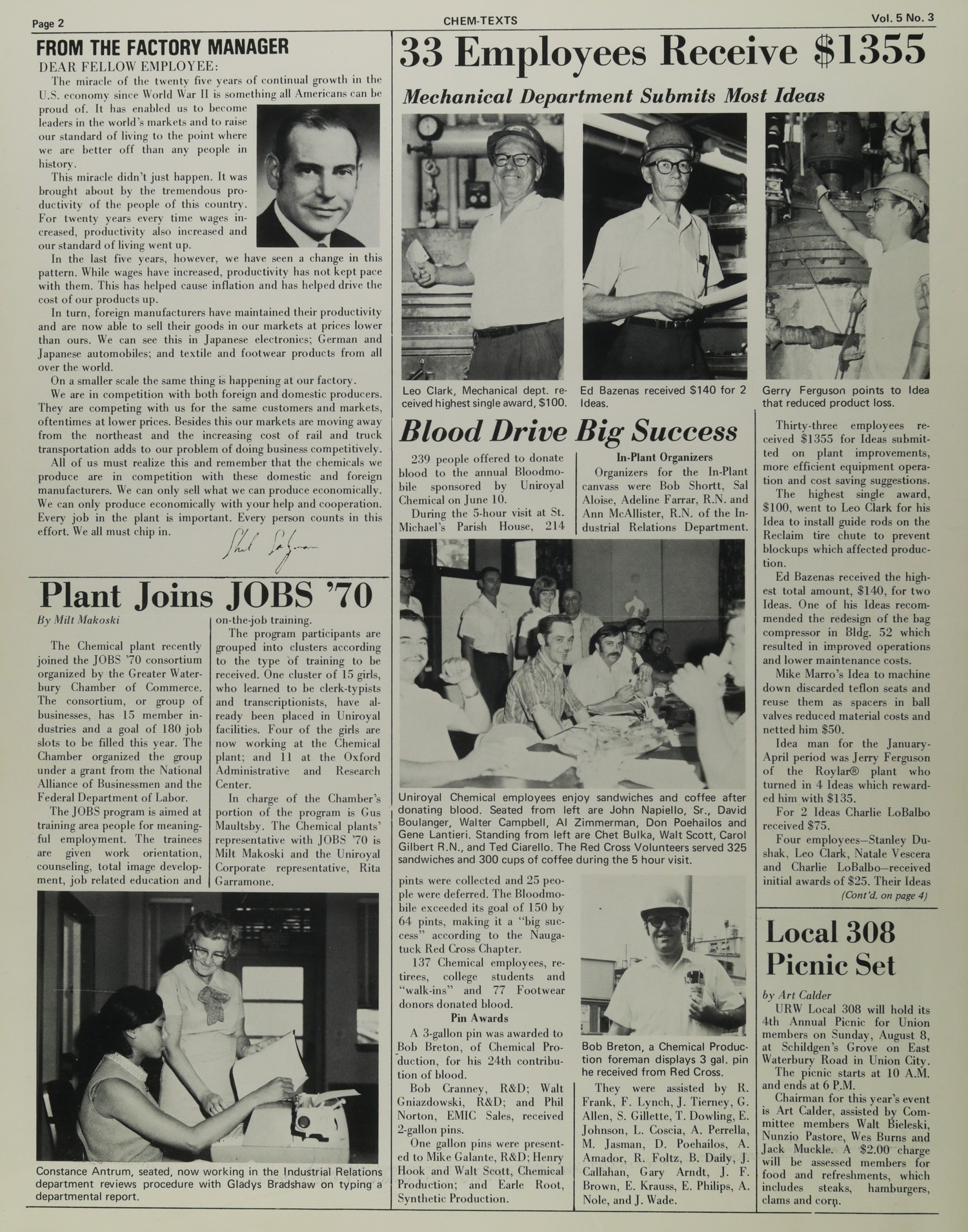

Leo Clark, Mechanical dept. received $100 for 2 ideas.

Blood Drive Big Success

230 people offered to donate blood to the annual Bloodmobile sponsored by Uniroyal

on June 10.

During the 5-hour visit at St. Michael’s Parish House, 214 pints were collected.

In-Plant Organizers

Organizers for the In-Plant Canvass were Bob Shortell, Sal Lanni, Adeline Barger, R.N. and Ann McMAlister, R.N. of the Industrial Relations Department.

Uniroyal Chemical employees enjoy sandwiches and coffee after donating blood. Seated from left are John Napellio, Jr., David Boultinghouse, Walter Gasparoni, Al Jarmuzewski, Carol Gilbert R.N., and Ted Giacclo. The Red Cross Volunteers served 325 cups of coffee during the 5 hour visit.

A certificate was awarded to Bob Breton, a Chemical Producer foreman, who displayed 3 gal. pin he received from Red Cross. There were assisted by R. Franks, F. Lynch, J. Tierney, G. Allen, S. Gilbert, J. Dowling, E. Johnson, L. Coscia, A. Perella, H. Assman, D. Pogliblo, A. Amador, B. Foltz, B. Daly, J. Callahan, G. Armit, L. F. Brown, E. Krauss, E. Philips, A. Nelis, and J. Wale.

Gerry Ferguson points to idea that reduced production costs and more efficient equipment operation and cost saving suggestions. The highest single award of $100, went to Leo Clark for his idea to install guide rolls on the Reclaim line to prevent blockings which affected production.

Ed Bazenas received $140 for 2 ideas of his ideas recommended on plant improvements, more efficient equipment operation and cost savings suggestions.

The highest single award of $100, went to Leo Clark for his idea to install guide rolls on the Reclaim line to prevent blockings which affected production.

Ed Bazenas received the highest total amount, $140, for two of his ideas recommended on the redesign of the bag compressor in Bldg. 52 which resulted in improved operations and lower maintenance costs.

Mike Marro’s Idea to machine down discarded teflon spacers for reuse as spacers in ball valves reduced material costs and netted him $50.

Idea man for the January-April period was Jerry Ferguson of the Roylands plant who turned in 4 ideas which reward ed him with $135.

Four employees – Stanley Daskal, Leo Clark, Natale Vesce, and Charlie Lobalbo – received initial awards of $25. Their ideas are continued on page 4.

Local 308

Picnic Set

By Art Calder

URW Local 308 will hold its 4th Annual Picnic for Union members on Sunday, August 8, at Schildgens Grove on East Waterbury Road, Middlebury.

The picnic starts at 10 A.M. and ends at 6 P.M.

Chairman for this year’s event is Art Calder, assisted by Committee members Walt Belski, Nunzio Pastore, Wes Dynis and Jack Muckle. A $2.00 charge will be assessed members for food and refreshments, which includes salads, hamburgers, clams and corn.

—

## Page 003

Drug Plan Starts

The new Prescription Drug Plan, the most recent of Uniroyal’s employee benefits, becomes effective July 1. The Plan will be carried by the Metropolitan Life Insurance Co.-Metropolitan.

Included in the Plan are the employee and eligible dependents-a spouse, any unmarried children under 19 years of age including step-children or other children who live with you and are dependent upon you for support and maintenance. All unmarried children over 19 years of age are also covered if they are either full time students or mentally or physically incapable of self-support.

ID Cards have been issued to participating employees. An employee with a family should have 2 cards-one for the employee and one for a spouse.

If you have not received an ID card or a Prescription Drug Plan booklet ask the Foreman or Supervisor of the department for them, or call Marion Butt Ext. 557.

“Keep Plant Beautiful”

New Corporate Concept

The Center has been described as a new “plant-ranch concept” as a “modern Oxford University”; and as a “skyscraper sideways.” It utilizes open office landscaping and has a minimum of individual offices. Privacy is attained through the strategic placement of plants and colorful screen dividers.

New Stock…

When George Pla, Uniroyal’s president and chairman, toured the Chemical plant a few years ago, one of the more impressive features he found in the plant was the flower boxes of petunias, zinnas and marigolds. In the photo above he waters the flowers which add a distinct color to the south end of the Chemical yard.

“With our new heart is laden” is the inscription on the faces of the 340 pure bred Polled Hereford calves being raised for prize showings and choice table beef at New Oxford…

Uniroyal Farms where 340 pure bred Polled Hereford calves and prize bulls are being raised for prize showings, commercial breeding and choice table beef.

Airport Facilities

Uniroyal also operates the nearby Oxford Airport and is renting hangar space, selling fuel to aircraft, and providing maintenance and repair services. A new Main Terminal is now open with 6 scheduled airline flights daily offered by Pilgrim Airlines.

Grounds Open To Employees

The Oxford grounds are open 7 days a week to Uniroyal employees, their families and friends but the buildings are closed during weekends.

The Cafeteria serves breakfast, lunch, and dinner Mondays-Fridays and is also open for dining on weekends: 6:30-8:30 P.M. however, reservations should be made in advance.

Guest House, Cocktail Lounge & 18 room guest house, cocktail lounge, and public dining room are also open to employees, their families and friends. The lounge is open from 5 P.M.-12 P.M. on weekdays; from noon to midnight on Saturdays; and from noon to 10 P.M. on Sundays.

Kralastic® ABS, a tough plastic product of the Chemical division, is being used for the drain, waste and vent plumbing system in the Research center.

Outdoor patio covers underground 250,000 gallon water storage tank which supplies water for facilities.

Plant’s Chemicals Protect Float

In a pool, on a beach or the buoyancy or usefulness. Especially against oxygen, ozone, heat and sunlight, several Naugatuck chemicals made at the plant are used. Without them, the rubber would deteriorate in a short time and the product have little value to the consumer.

SAFETY IS MY RESPONSIBILITY

—

## Page 004

Here is the text extracted from the document image, preserving the layout and structure as much as possible:

Know Your Products:

Rubber Chemical Accelerators

by Dr. Bob Brown

(This issue continues the article in Vol. 5, No. 2 on Accelerators made or marketed by the Naugatuck Chemical plant.)

Rubber chemical accelerators are used primarily to speed up, or control the vulcanization process which turns rubber from a useless, gummy substance into a strong resilient and elastic material. Vulcanization, in simple terms, is a chemical reaction between rubber and sulfur, usually brought about by heat.

Faster Accelerators

Where there is increasing or mixing involved, very fast accelerators with little or no delayed action can be used to give more rapid vulcanization.

The Zates (Arazate®, Butacite®, Ethazate®) and the Thiurams (Methazate®, Tetrone®, Tuex®, and Accelerator 100) are used here. They are also used in latex mixing where processing is usually not a problem.

Customers use these accelerators for rubber goods, wire insulation, hot water bottles, conveyor belts, hospital sheeting, and household items and in such items products as balloons and carpet backing.

Late Accelerators are antidegradants and can be used in colored rubber products.

Some of the newer synthetic rubbers (Royalene® – the “crackless rubber”) in tire and other applications are more demanding and require faster vulcanization than the older types and their mixes necessitates accelerators such as Naugazol® and Parrex® synthetic rubbers made at the Naugatuck and Painesville, Ohio plants.

Fast accelerators are needed to speed up the vulcanization process for these types of rubber, otherwise it would be economically impossible to make a product at a reasonable selling price to the consumer.

33 Employees Three Retire In Month

(continued from page 2)

are under further evaluation for higher amounts dependent on the amount of the savings for the plant.

Other employees who received cash awards for Ideas were P. Riskie, F. Malfin, M. Jannely, D. Stevenson, E. Griskas, R. Graci, B. Robinson, A. Urban, S. Kropcho, J. Harper, J. Gilbert, A. Haggy, J. Rask, H. Garhau, P. Surmanak (2), L. DeLetros (2), P. Beardsly, S. Palone, H. Hernandez, A. Gresh, J. Needham, D. Boyd, E. Root, Sr., A. Molnar, D. Pinto and J. Cohen.

Letters of Commendation were presented to C. Smith, L. Fortier, F. Gagne, Carol Gale, J. Gallucci, R. Lockwood, D. Donato, L. Carr, Preciosa Gravo, D. Nelson, A. Navuge, W. Krayski, A. Wislaski and D. Pottorff.

Of the 33 employees awarded for Ideas, 10 were salary employees and the highest sumer submitted by Mechanical Department personnel.

No Limit to Cash Awards

There is no maximum limit to the amount of a cash award for an Idea. If the value of the Idea exceeds $1,000, this amount is paid under the Plant Idea Plan – if it is submitted for further consideration for a higher award to a special management committee. The minimum award for an Idea is $25.

Ideas to Conserve Water Needed

With the construction of the new liquid waste pretreatment plant in progress, ideas to conserve water are needed now as the facilities are designed to treat 3,600,000 gallons a day.

SAFETY IS MY RESPONSIBILITY

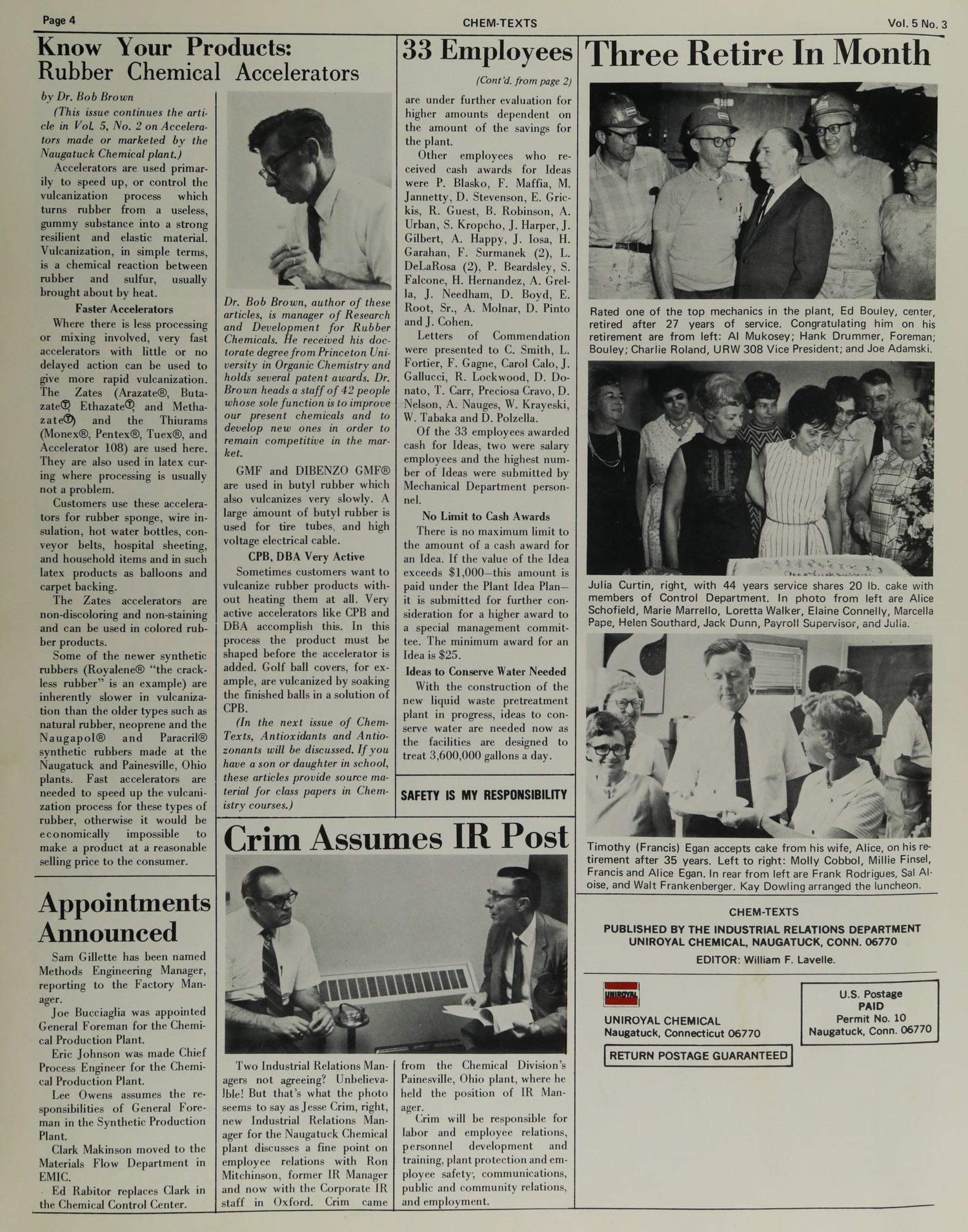

Crim Assumes IR Post

Two Industrial Relations Men not agreeing? (Unbelievable! But that’s what the photo seems to say as Crim, right, new Industrial Relations Manager for the Naugatuck Chemical plant discusses a fine point on employee relations with Ron Mitchinson, former IR Manager and now with the Corporate IR staff in Oxford. Crim came from the Chemical Division’s Painesville, Ohio plant where he held the position of IR Manager.

Crim will be responsible for labor and employee relations, personnel development and training, plant protection and employee safety, communications, public and community relations, and employment.

Timothy (Francis) Egan accepts cake from his wife, Alice, on his retirement after 35 years. Left to right: Molly Gobbel, Millie Finsel, Francis and Alice Egan. In rear from left are Frank Rodriguez, Sal Aloise, and Walt Frankenberger. Kay Dowling arranged the luncheon.

PUBLISHED BY THE INDUSTRIAL RELATIONS DEPARTMENT

UNIROYAL CHEMICAL, NAUGATUCK, CONN. 06770

EDITOR: William F. Lavelle.

U.S. Postage

Paid

Permit No. 10

Naugatuck, Conn. 06770

RETURN POSTAGE GUARANTEED

—

## Page 191

CHEM-TEXTS

Vol. 5, 1971 PUBLISHED FOR THE PEOPLE OF UNIROYAL CHEMICAL No. 3

New Oxford Center Opens

New Stock

Plan Offer To Employees

Uniroyal’s new Management and Research Center officially opened on July 12 after nearly 3 years of construction.

Some 400 people moved into the granite and bronze-tinted glass structure that is fully air-conditioned, sound-proof, and set securely on 118 acres of woodlands and farmland.

The option price will be the median market price of Uniroyal common stock on August 10, 1971.

No later than Sept. 8, 1971, an eligible employee may elect to purchase all or part of the Common Stock Purchase Plan.

35 Enroll; 22 Increase Bonds

35 additional employees enrolled and 22 increased their participation in the purchase of U-Bonds during the campaign recently conducted at the Chemical plant. 50% of employees, or 33%, now purchase E Bonds through the U.S. Payroll deduction plan. The E Bonds pay a guaranteed 5% interest rate to maturity, 5 years and 10 months.

Bond purchases can be made any time through the payroll savings plan by contacting Molly DeCicco, Ext. 218.

Polled Herefords

THE BIG BOLD BREED

UNIROYAL, INC.

The Administrative Center, a glass and granite structure set in scenic woodlands, is one of industry’s most modern corporate headquarters. It houses a vast computer system and other corporate functions. These groups will continue to operate from 1230 in New York City. The other facility is the combined Cafeteria, Guest House, and Corporate Conference Center.

The Research Center, the largest of the buildings, will open about June 1972 and will consolidate the Corporate Research and Development facilities of the Consumer, Industrial, and Plastic products divisions. The laboratories will have the most modern equipment and facilities available in the industry.

Ultimately 1500 employees will be located at the Complex. Near the site are the two Uniroyal Farms.

The Research Center, which will be completed in 1972, will consolidate Corporate, Consumer, Industrial, and Plastic products research and development.

Training sessions for employees will be conducted at the Corporate Conference Center. It features a cafeteria, guest house, cocktail lounge and dining facilities which are open to employees and their families.

—