## Page 002

Here is the extracted text from the document image, preserving the layout and structure as much as possible:

FROM THE FACTORY MANAGER

DEAR FELLOW EMPLOYEE:

Once again the United Givers of Naugatuck-Beacon

Falls is starting its Fall drive to raise funds for the oncom-

ing year.

As you know, these funds sup-

ply finances to a great many very

worthwhile activities carried out in

Naugatuck, Waterbury and sur-

rounding towns in which we live.

Each year the Factory has con-

tributed collectively a substantial

sum of money to help these worth-

while activities.

This year the drive will be con-

ducted with Jim Carroll as Chair-

man. Jim has formed his Committee and his canvassers will

be approaching you shortly for your contribution.

Uniroyal Chemical people have always shown a splendid

generosity in their pledges to support the work of these

Agencies. Last year, more than two thirds of the Chemical

people contributed $20,066. For an average contribution

of $20.

Our goal is $21,000. We can achieve this if we give

“where you work” and pledge through the payroll deduc-

tion plan.

If each person would contribute a minimum one hour’s

pay per month, we will readily raise the necessary money

to help continue these activities which in some way benefit

virtually every employee or some member of his family.

/s/ Del Dayo

3 Women Officers Named

Discussing plans for the Club’s activities are the newly elected offi-

cers from the Chemical Plant. From left, Marge Lasky, secretary;

Helen Lavery, vice-president; and Penny DiBenadictis, treasurer.

These Uniroyal Chemical

women were named officers in

the Uniroyal Girls’ Club at its

annual dinner meeting held at

the Waverly Inn.

Helen Lavery, EMIC, was

named Vice-President; Marge

Lasky, Research and Develop-

ment, was elected Secretary; and

Penny DiBenedictis, EMIC, was

made Treasurer.

53 Chemical people belong to

the organization which offers a

Scholarship each year and parti-

cipates in many community ac-

tivities.

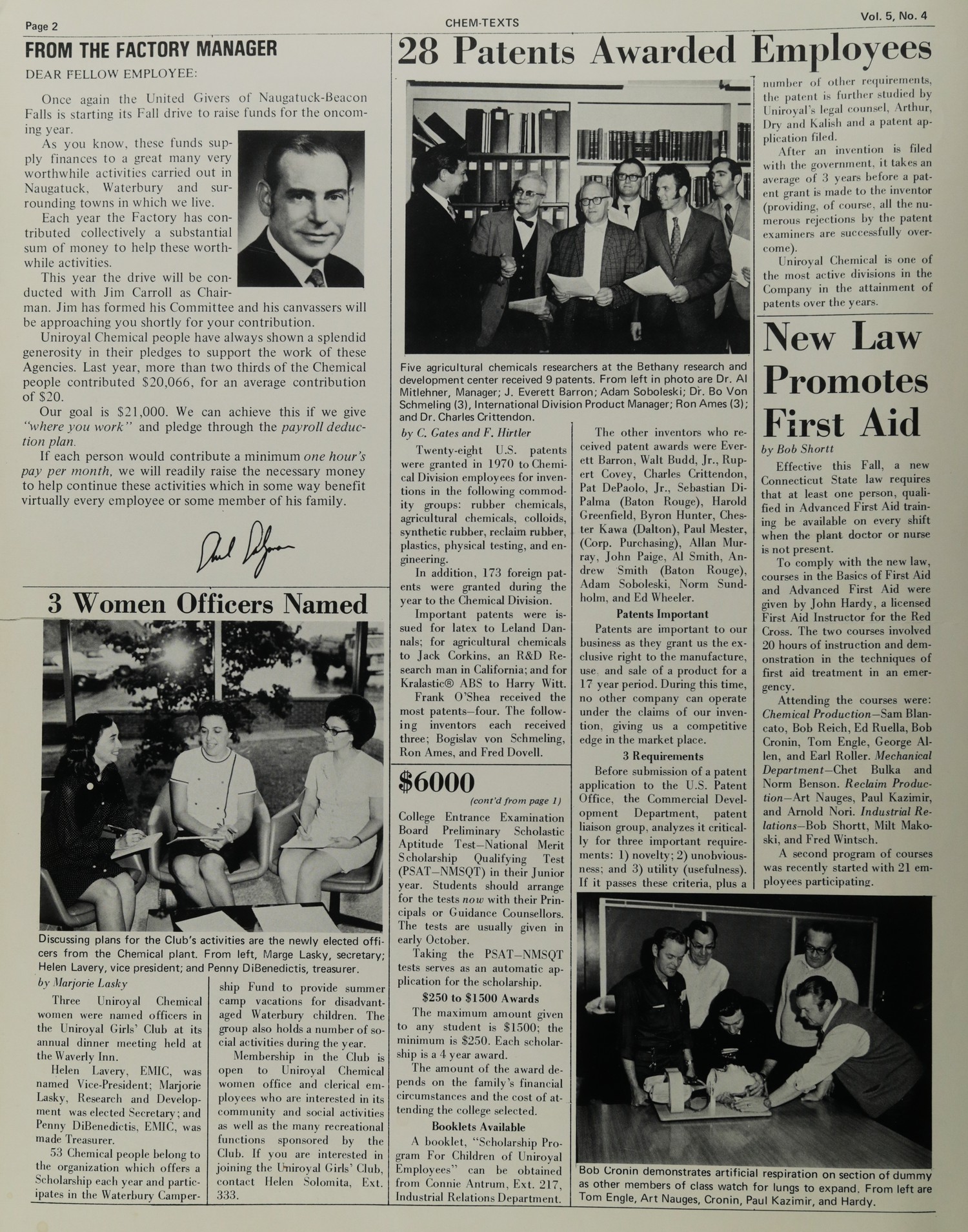

28 Patents Awarded Employees

Five agricultural chemicals researchers at the Bethany research and

development center received 9 patents. From left to right are Dr. Al

Mittlehner, Manager, J. Everett Barron, Adam Soboleski, Dr. Ira Von

Schneibing (J.), International Division Product Manager, Ron Ames (J.)

and Dr. Charles Garrison.

In C. Colvin and F. Handy,

Twenty-eight U.S. patents

were granted in 1970 to Chemi-

cal Division employees for inven-

tions in the following common-

ly groups: rubber chemicals,

agricultural chemicals, antidock-

ing agents, tire cord, synthetic

rubber, reclaim rubber,

plastics, physical testing, and en-

gineering.

In addition, 173 foreign pat-

ents were granted during the

year to the Chemical Division.

Important patents were is-

sued for Lites to Roland Dan-

nals, for agricultural chemicals

to Jack Gosline, an R&D Re-

search man in California, and for

Krakatox ABS to Harry Vin-

Frank O’Shea received the

most patents-four. The follow-

ing employees also received mul-

tiple patents: Bogelian von Schle-

ckenrider, Hal Fried Doehl,

and Fred Duvall.

$6000

(cont’d from page 1)

College Entrance Examination

Board Preliminary Scholastic

Aptitude Test National Merit

Scholarship Qualifying Test

(PSAT-NMSQT) in their Junior

year. Students should arrange

for the tests now with their Prin-

cipals or Guidance Counselors.

The tests are usually given in

early October.

Taking the PSAT-NMSQT

tests serves as an automatic ap-

plication for the scholarship.

$250 to $1500 Awards

The maximum amount given

to any student is $1500; the

minimum is $250. Each scholar-

ship is a 4-year award.

The amount of the award de-

pends on the family’s financial

circumstances and the cost of at-

tending the college selected.

Booklets Available

A booklet, “Scholarship Pro-

gram for Children of Uniroyal

Employees” can be obtained

from Connie Antrum, Ext. 217,

Industrial Relations Department.

number of other equipment.

the patents is further qualified by

Uniroyal’s legal counsel, Chief Pat-

ents and Trademark Attorney.

After an invention is filed

with the Patent Office, it takes an

average of 3 years before a pat-

ent is granted. (It is during this waiting period, of course, all the num-

erous corrections by the patent

examiners are successfully over-

come.)

Uniroyal Chemical is one of

the most active divisions in the

Company in the attainment of

patents over the years.

New Law

Promotes

First Aid

by Bob Shortt

Effective this Fall, a new

Connecticut State law requires

that at least one person, quali-

fied in Advanced First Aid train-

ing be available on every shift

when the plant doctor or nurse

is not present.

To comply with the new law,

courses in the Basics of First Aid

and Advanced First Aid were

given by John Hardy, a licensed

First Aid Instructor for the Red

Cross. The two courses involved

20 hours of instruction and dem-

onstration in the techniques of

first aid and treatment in an emer-

gency.

Attending the courses were:

Chemical Production – Sam Bia-

lato, Bob Reitch, Ed Reidla, Bob

Groom, Tom Eagan, George At-

toun, and Earl Roller. Mechanical

Department – Chet Bulka and

Norm Benson. Reclaim Produc-

tion – Art Nunes, Paul Kazimir,

and Arnold Dziadik. Industrial Re-

lations – Bob Shortt, Milt Mako-

ski, and Fred Winsch.

A second program of courses

was recently started with 21 em-

ployees participating.

Bob Cronin demonstrates artificial respiration on section of dummy

as other members of class watch for proper form. From left are

Tom Eagan, Art Nunes, Cronin, Paul Kazimir, and Hardy.

—

## Page 003

Here is the text extracted from the document image:

New Research Laboratory Studies Pollution Causes

Dr. Jim Brown, left, discusses results of Microbiology Sensitivity Test with, from left, Dr. Dave Liu, Irwin Prager, Suren Semonian, and Dr. Charles MacCleary, Director of Research and Development.

The test assigns the sensitivity levels of the microorganisms used in the biological secondary treatment process.

If chemistry can cause pollution, the chemical industry should be able to solve the problems of pollution. This is the philosophy behind the new Pollution Abatement Laboratory recently opened by the Research & Development department near the Tire Gate entrance.

The $70,000 structure, which will cost approximately $100,000 a year to operate, is equipped with all the necessary equipment for performing water and waste stream analyses in support of our more concentrated work in all aspects of pollution abatement for the Chemical Division plants. The laboratory will be the center of all division activities in water and air pollution control, ranging from pilot scale biological treatment systems and toxicological evaluations of the effects of various materials on aquatic life to developing specialized chemical engineering unit operations techniques for pretreating difficult-to-handle liquid wastes.

Oliveira, The Music Man

As a hobby, Joe Oliveira, one of the plant’s carpenters, makes violins and is also an accomplished musician. Joe uses spruce wood which are worth $500 to $600 each.

Two of the violins he has made over the years are used by his twin sons, One plays in the Houston, Texas Symphony and the other is a concert violinist in New York.

It takes Joe about 10 hours to make a violin.

Group Tops 750,000 lbs. No Rejects

On January 1, Strong Scott operators, Henriques Marques, Tony Rebelo, and Harry Searl started a production run of BIK and BIK-OT which resulted in over 750,000 lbs. of the chemicals without a reject for quality. The long run ended on June 10 when the first batch in 5 1/2 months was off-spec.

Both chemicals have presented serious quality problems over the years because of their reaction to humidity changes which affected the grinding operation. Previously, it was not rare for a batch to be off-spec and the chemicals had to be reprocessed which greatly increased the cost of the products and reduced or eliminated their profit.

According to Jim Gravo, Foreman of T3 Bldg., it turned up to 10 hours per man and our efforts wasted. One day we lost our leader together and he called in technical assistance from the Process Engineers on the job we could not lick, and they were able to come up with new approaches to the problem and advised us on new turnabout in quality improvement. Our goal challenge now is to top the 1,000,000 mark.

Profits (cont’d from page 1) compared with the previous record of $817,538,000, last year.

Net income for the six month period was $26,100,000, equivalent to 88 cents a common share, and represented a gain of 15% compared with the $22,700,000, or 73 cents a share, reported last year.

Division Sales Off

Sales and earnings for the Chemical division were down for the first six months of the year, still materially below last year’s figures.

Sales in chemicals were below budget and face severe price competition from domestic and foreign products.

Recently we lost one of our major customers which took this product, generally the profits of this unit. Cellulose and Naugahyde are not in a good position.

Quiet Summer For Residents

A new silencer controls noise of compressor in power plant. The loud vibration from the compressor caused noise pollution for employees and neighbors. Checking operation of silencer at power plant from N-Gugure, George Aradi, and Jose Marine.

“noise problem locations” such as hospital areas.

A complete revision of the present facility, changes in the building and discharge piping, and improvements in the compressor installation is recommended Engineering, Inc.

Since the installation, no complaints from the Naugatuck residents on the East Side of the town.

Jim Gatling performs an analysis test for mixed liquor suspended solids and mixed liquor volatile suspended solids to determine the total solid content and the determination of the number of organisms in the sludge.

Jack Paul examines the activated sludge under the microscope to identify the microorganisms present in the material.

The Chemical plant is contributing $1,500,000 to the construction of this facility. The Chemical plant is also building a $3,000,000 liquid waste pre-treatment (primary) plant in the south reclaim yard, which is scheduled for completion in December 1972.

Cafeteria Remodeled

Remodeling of the Synthetic Cafeteria was recently completed. Attractively redecorated with new floral design drapery, bright ceiling lights, and colorful chair coverings, the dining room matches eating places in the area.

The cafeteria is in Bldg. 1.

—

## Page 004

Page 4

Know Your Products:

Naugatuck® Chemical Antioxidants

by Dr. Ralph Brown

(This is the third in a series of

articles on the chemicals manufactured in Chemical Production

as sold by the Chemical Division.)

If we didn’t have antioxidants

and antiozonants, rubber products would fall apart, before we

could wear them out.

In fact, most kinds of synthetic rubber can’t even be manufactured without some type of

a protective chemical to get

them through the drying and

storage stages.

Polyguard®, for example, is

used extensively by the synthetic rubber plants as a stabilizer

(or antioxidant) during processing and manufacture. It is not

only an excellent antioxidant

but it does not discolor or stain

the rubber, therefore it can be

used for white and light colored

rubber articles.

If the rubber is to be manufactured into a black or dark

colored product (tires, etc.) then

the customer may prefer to use

Poly-Gard which discolors the rubber, but also carries the protection over into the finished

product to a greater extent than

Polyguard.

New Chemicals Developed

For Synthetic Rubbers

The newer types of synthetic

rubber required new types of antioxidants to protect them

against oxygen and heat deterioration.

Antioxidant 451 was especially

Plant Safety

(continued from page 1)

and is still in the Intensive Care

unit of St. Mary’s Hospital.

Disaster Plan Operates

A few minutes after the explosion members of the Disaster

Plan arrived at the plant and assumed their responsibilities during the emergency. One evidence

of the Plan’s effectiveness was

the swift medical attention provided the injured employee-he

was receiving medical care by a

team of specialists at St. Mary’s

Hospital ten minutes after the

accident.

The cause of the explosion is

still under investigation.

Other Accidents In Period

Other injuries during the 8

week period were: one employee

suffered partial loss of a finger;

an employee cut his hand with a

knife requiring ten stitches; another employee dropped a valve

on his foot and broke a toe; and

an employee injured his eye when

a flying chip struck his eyeball;

two employees suffered severe

burns from steaming hot water

and a steam hose; and another

employee broke an ankle when a

ladder slipped and he fell off it

backwards.

Where Accidents Occurred,

July 10 to Sept. 4

Dept.

Lost

Serious

Time

Injuries

Chem. Prod.

4

1

Reclaim. Prod. 3

2

Syn. Prod.

3

1

Materials

0

1

Mechanical

1

0

Res. & Devel.

1

0

TOTAL

12

9

Tutors Needed

For Program

Two Employees Retire

Bill Pearson, third left, retired from the Industrial Engineering dept.

after 21 years. Congratulating him from left are Don DeSalange,

Harry Francolini, and Jim Sullivan were transferred to Baton Rouge, La.

Vladas Vaicainis, Materials Department, retired after 20 years service. In photo from left are Joe Cozanski, Paul Guerra, Sam

Korpusik, Vaicainis, Bud Biddall, Frank Lynch, and Bill Bachunas.

Golf League

End Season

Vol. 5 No. 4

Ennami Family

Thanks Employees

by Hank Butkoski

The Uniroyal Synthetic Golf

League ended the season with

Hank Drummer and Dan Petru

taking first place honors with

John Mocke and Jack Painter

runners-up.

Suffering a sudden death playoff last summer, Drununer

and Petru showed fine short iron

play, classic drive shots and good

putting to take this year’s title.

Bob and Jean Ennami extend their sincere thanks to

employees for the $1,271

which was presented to the

Ennami family recently.

Bob Ennami was seriously

injured in the Chemical Pilot

plant when a 20 gallon reactor

exploded. He has been hospitalized with third degree burns

since Aug. 17 at St. Mary’s

Hospital.

by Len Lombardi

The Uniroyal Tutoring Program, now in its second year,

needs additional tutors to expand its activities to the Puerto

Rican young people in Waterbury.

The program provides personal instruction to youngsters to

help them become better achievers in school, obtain a High

School diploma and continue

their education.

Every eight Uniroyal Chemical employees tutor on Monday

evening from 7 to 9 P.M. at the

Sisters of Charity’s tenant

house on Gilbert St.; and at the

Woodrow Wilson School on

Tuesdays.

If you are interested in helping these young people, contact

Len Lombardi Ext. 296.

CHEM-TEXTS

PUBLISHED BY THE INDUSTRIAL RELATIONS DEPARTMENT

UNIROYAL CHEMICAL, NAUGATUCK, CONN. 06770

EDITOR: William F. Lavelle.

GIVE “WHERE YOU WORK”

Smoking Expensive

The average smoker smokes 1

package of cigarettes a day. He

pays 37 cents a pack. At the end

of a year he or she will have

spent $208.

U.S. Postage

PAID

Permit No. 10

Naugatuck, Conn. 06770

RETURN POSTAGE GUARANTEED

UNIROYAL CHEMICAL

Naugatuck, Connecticut 06770

George Lewis, seated center, who recently retired, listens to Flavio

Martinello, former Local 218 President and a retiree, reminiscing about

the “good old days”. Others in the photo are standing from left: Joe

Harper (vice general), Walt Anderson, Jack Hoey, Sam Massaro, Joe

Simone, and Mario Inello. Seated from left are Jim Shea, John Holland,

Lewis, and John Siensky.

The URW Local 218 of the

Chemical plant held its fourth

annual picnic at Lake Quassapaug, sponsored by the Union

during the summer. The picnic

gave members in different departments of the plant an opportunity to meet new members,

people on different shifts and

brings back a number of retirees

to reminisce about the “good

old days”. The success of the

affair was attributed to the

months of planning by Frank

Conommelle, Chairman, and

members of the Picnic Committee: Frank Wasilewski and John

Lengvel.

Activities started at 1 P.M.

with charcoal-broiled hamburgers

and cold refreshments. Steaks

and corn were served at 5 P.M.

—

## Page 195

UNIROYAL CHEM-TEXTS

Vol. 5, 1971 PUBLISHED FOR THE PEOPLE OF UNIROYAL CHEMICAL No. 4

$6000 Awards Offered

10 Uniroyal scholarships will be awarded to children of employees with five or more years of service – who attain the highest finalist qualification in the annual scholarship competition conducted by the National Merit Scholarship Corporation. Scholars are chosen on the basis of scholastic aptitude, leadership and good citizenship. The Company plays no part in the selection of the scholars.

No Application Required

Eligible high school students must take the new combined PSAT/NMSQT test (see page 2)

Profits; Sales Up

Chemical Sales for the quarter increased 18.1% for the second quarter of 1971 compared with the second quarter of 1970.

Sales for the quarter set a new record of $104,101,000, a gain of 6.3% compared with the previous record of $97,714,000 set last year.

Net income for the Company increased 18.1% for the second quarter of 1971 compared with the second quarter of 1970.

Plant Safety Record Marred By Injuries

Explosion ripped interior walls of Pilot Plant; shattered windows; and tore hole in roof. The structural steel framework of the building was not affected.

Since July 10, 6 accidents occurred in the plant when 21 employees were injured in an 8 week period. Twelve were lost time accidents in which employees required hospital treatment; the others were serious injuries requiring treatment by the plant nurses.

The explosion of the Chemical Pilot Plant, Aug. 22, was the most significant accident for the Company in several years. A 20 gallon explosion causing a flash fire in the building and extensive damage to the piping and equipment.

The heat of the fire spread up the sprinkler system flooding the area with water. It was the alert action of Chris Owens, who narrowly escaped injury from the blast, and Al Grella, that was greatly responsible for extinguishing the fire and preventing greater damage to the area.

The employees of the Chemical Department were seriously burned with the explosion. The incident caused over 20% of his face and chest to be burned.

Dividend Declared

Uniroyal declared a dividend of 17 1/2¢ a share on the Company’s common stock. The dividend was payable Sept. 25 to stockholders of record Aug. 25.

The Company also declared a dividend of $2 a share on the 8 percent first preferred stock. It was payable Sept. 25 to holders of record Aug. 25.

Employees Clean-Up River

Materials department group points to discarded tires recovered from the Naugatuck River. From left are Stan Korpsuk, Joe Trangle, Vladas Krakauskas, and Frank Lynch. Not present was Adolf Lee.

By Bob Van Allen

Five Uniroyal Chemical Employees recovered 75 discarded tires from the Naugatuck River during “Clean Up” week.

The Clean-Up started when Stan Korpsuk and Frank Lynch of the Materials Department toured the river’s banks from Beacon Falls to locate the tires thrown into the river.

For three days Joe Trangle, Vladas Krakauskas and Adolf Lee covered a 20 mile area to pick up the tires and truck them to the Reclaim plant.

GIVE “WHERE YOU WORK”

—