## Page 002

Here is the extracted text from the document image, preserving the layout and structure as much as possible:

CHEM·TEXTS

Hydraulic Staging

Purchased For Plant

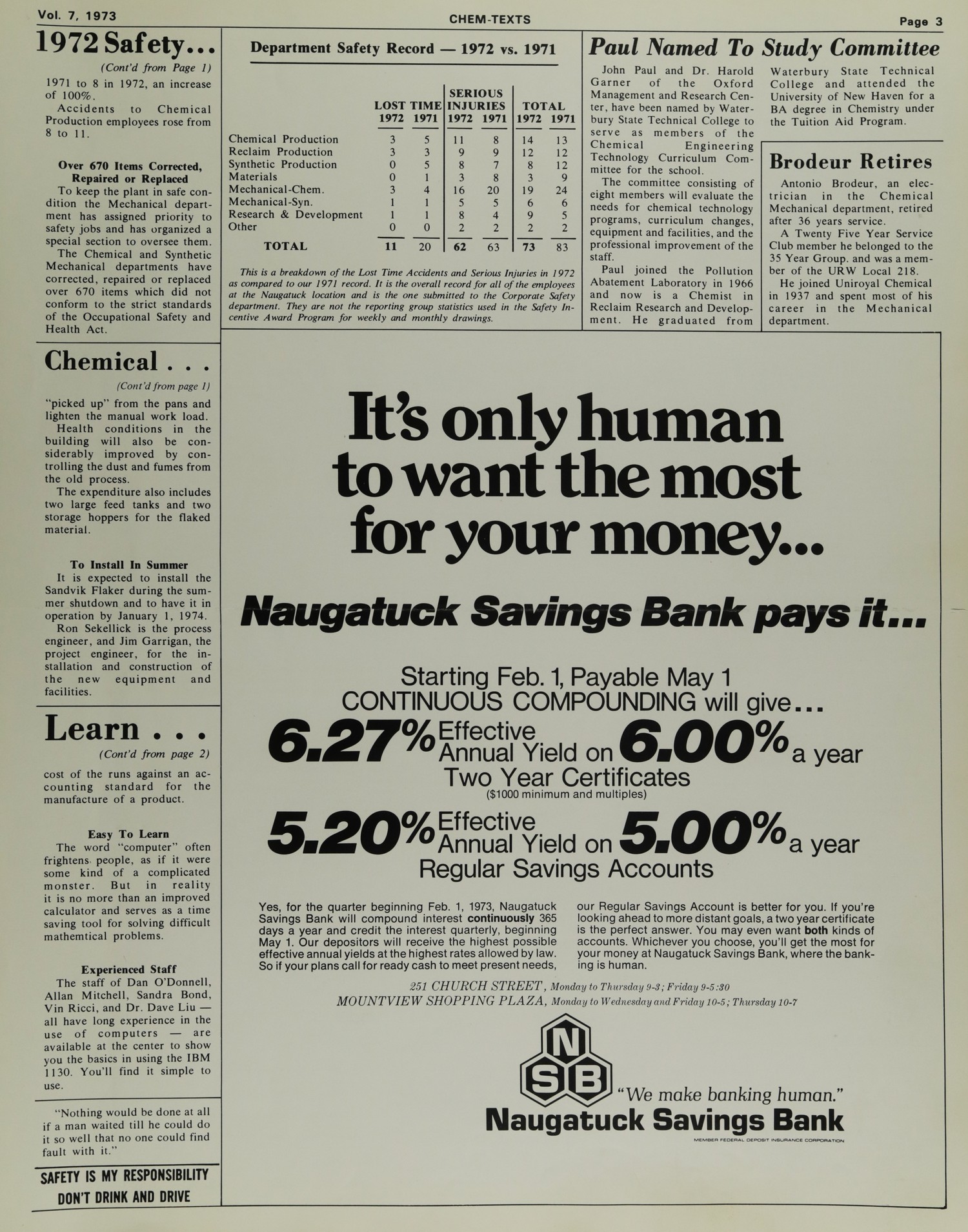

Jack McCarthy demonstrates the ease of operating the new hydraulic

staging as he inspects equipment in a chemical production building.

by Ian Kladowski

The sensor and platform

access in buildings of the

Chemical Mechanical depart

ment.

With the push of a button, the

new, semiautomatic, hydraulic

staging will lift a thousand

pounds of stage and equipment

to a height of 17 feet in a few

minutes.

It replaces the old pipe

staging that took over six

manhours to assemble and

disassemble and oftentimes

wobbled when installed at a job

site.

The portable staging can be

used practically anywhere in the

plant and set up in a few

minutes. It is safer, more of a

one-man operation, less than

staging for high places and is

part of a continuing program by

the Mechanical Department to

improve work methods and the

safety of people exposed to

hazardous situations.

Scholarship

Offered

Computer Easy To Use

by Kevin Kelley

The Uniroyal Chemical

Management Club will again of

fer a $300 scholarship ($250

from the Management Club and

$50 from Uniroyal Large-Montford) to a graduating high

school student who plans a

college education. To qualify

one of the student’s parents must

have worked for Uniroyal

Chemical at Naugatuck or

Bethany for two years or more.

The scholarship fund is sup

ported by the dues of members.

Applications can be obtained

from the Uniroyal Chemical

department, Bldg. 84 or by a

telephone call to Connie An

trum, Ext. 517.

The completed applications

must be returned to Irwin

Frager, Chairman of the

Scholarship Committee, on or

before April 1.

The last year’s scholarship was Maria Galante,

daughter of Mike Galante, a

research chemist in Reclaim

Production.

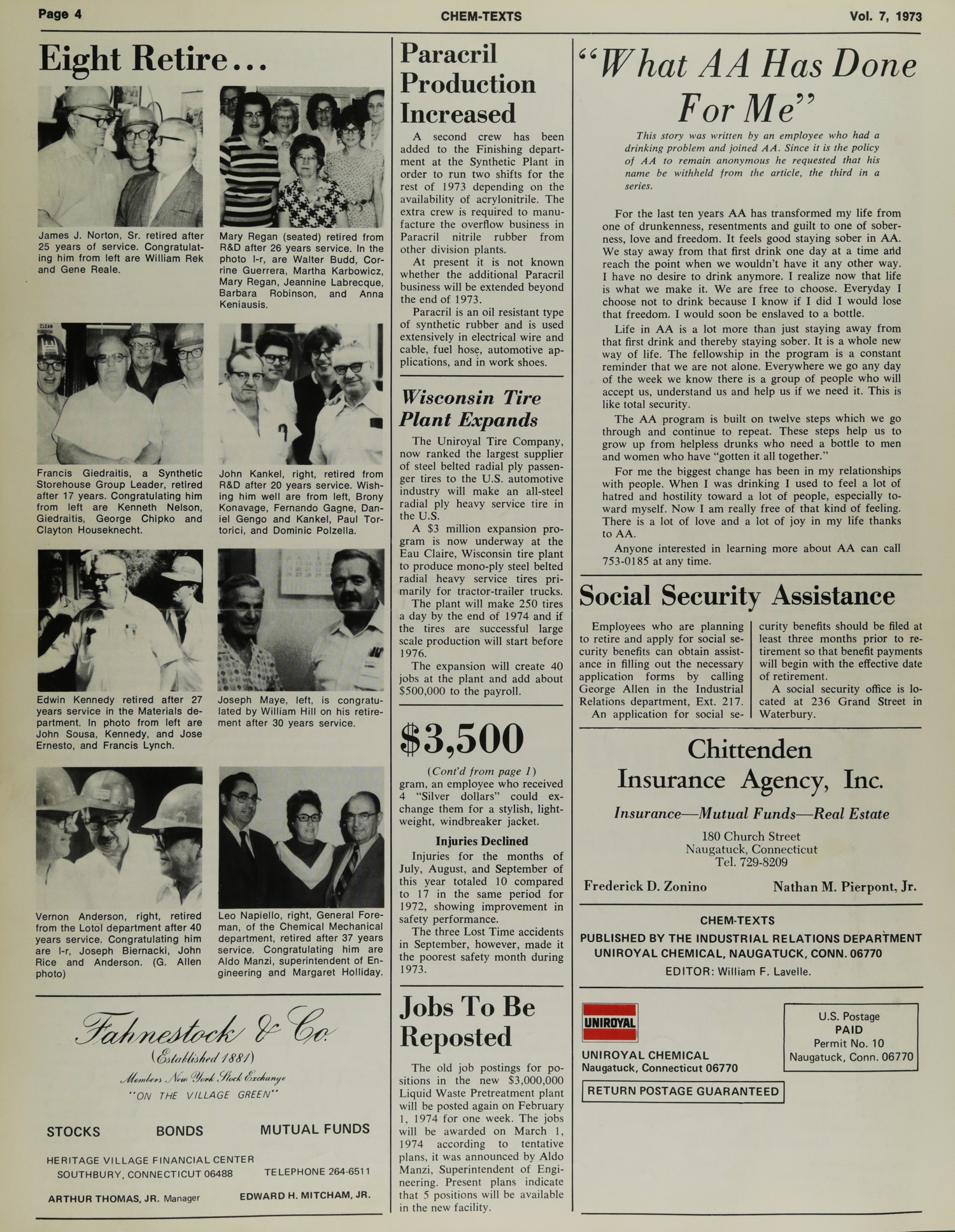

Dan O’Donnell and Alan Mitchell, rear, check the output as Vin Ricci

and Sandra Bonn prepare the input for a agricultural research

project.

Appointments

Announced

Garrett Sullivan has been

named Marketing Manager of

Chemicals and Synthetic Rubber.

Henry Smith has been ap

pointed Production Manager

for the Northeast area.

Robert Swallow has been

assigned to the position of

Material Troop Manager.

Robert Mazaika has been

named Marketing Manager for

Colloids.

Although it is not generally

known, the Research and

Development department main

tains a Math and Computer Ser

vices group and a small IBM

“1130” computer, both located

in Bldg. 11 adjoining the Syn

thetic Plant Fire House.

Eight commodity groups are

now using the IBM “1130” for

simulation studies, polymer

development, process ability,

information systems, and

statistical analysis.

The

group

provides

mathematical and computer ser

vices in the areas of technical

sales, research and develop

ment, accounting, or referrant

areas where statistical com

putations are involved. The ser

vices can be broadly divided

into two basic categories: com

mercial and scientific.

Develops Programs

An information reporting

system is now under complet

ion for use at the Naugatuck

Plant. The report monitors

month-to-date and year-to-date

production of the Synthetic on a

monthly basis. The computer

generated report also compares

actual production rates and the

$5096

(cont’d from page 1)

Idea Team of John Bukus and

John Planter of the Synthetic

Mechanical department, for the

several improvements they

suggested during the year.

Not far behind in the total

amount awards was Carmine

Lannuzzi, who received $415 for

the suggestions he proposed on

the Hydraulic single stage

crane. The plan, submitted by

the individual, went to Archie

Civiello of the Synthetic

Quality Control Lab.

Mechanical Department,

Most Prolific

Most ideas come from the

Mechanical departments, both

Chemical and Synthetic, where

imagination and creativity seem

to run high. Over the year they

received not only the highest

single cash awards but more

suggestions and improvements

for the year.

The Plan is completely

dominated by the wage per

sonnel with only about a third

coming from salaried personnel

who submit no ideas.

Some radicals seek needed

changes of voice legitimate

grievances. Others, with no

reasonable basis, file petitions

of anger, hate and destruction, using tac

tics that infringe on the

legitimate rights of their neigh

bors.

The decision to support or

oppose a radical position

requires careful examination of

the ends intended and the means

chosen.

—

## Page 210

Vol. 7, 1973

CHEM-TEXTS

Page 3

1972 Safety…

(Cont’d from Page 1)

1971 to 8 in 1972, an increase

of 100%.

Over 370 Items Corrected,

Repaired or 3 Replaced

To keep the mechanical equipment in safety, a Mechanical department has been organized a

special section to correct, repair

or replace items which did not

meet the Occupational Safety and

Health Act.

Department Safety Record — 1972 vs. 1971

Chemical Production

Reclaim Production

Maintenance Production

Materials

Mechanical-Chem.

Mechanical-Syn.

Research & Development

Other

TOTAL

LOST TIME

1972 1971

3

5

0

0

3

4

0

1

1

1

1

1

3

0

0

0

11

20

SERIOUS

INJURIES

1972 1971

11

8

9

4

3

8

3

8

5

5

5

4

8

4

2

2

62

63

TOTAL

1972 1971

14

13

12

12

19

21

5

9

11

11

6

5

11

4

2

2

73

83

This is a breakdown of the Lost Time Accidents and Serious Injuries in 1972

as compared to 1971 record. It is the overall record for all of the employees

of the Naugatuck division and is the one submitted to the Corporate Safety

department. They are not the reporting group statistics used in the Safety forward group. They are weekly and monthly drawings.

Paul Named To Study Committee

John Paul and Dr. Harold Waterbury State Technical

Garner of the Oxford College and attended the

Management and Research Cen- University of New Haven for a

ter of the New York Wester- BS degree in Chemistry, joined

bury State Technical College to the Turco Air Program.

serve as members of the

Chemical

Engineering Brodeur Retires

Technology Curriculum ComAntonio Brodeur, an elecmittee for the school.

The committee consisting of trician in the Chemical

eight members will evaluate the Mechanical department, retired

needs for chemical technology after 35 Years Service.

equipment and facilities, and the

A Twenty Five Year Service

instructional improvement of the Awards citation belongs to the

staff. 35 Year Group, and was a memPaul joined the Pollution ber of the URW Local 218.

Abatement Laboratory in 1966 He joined Uniroyal Chemical

and now is a Chemist in in 1937 and spent most of his

Reclaim Research and Develop- career in the Mechanical

ment. He graduated from department.

Chemical . . .

(Cont’d from page 1)

“picked up” from the pans and

tighten the manual work load.

Health conditions in the

building will also be considerably improved by controlling the dust and fumes from

the old process.

The expenditure also includes

two large feed tanks and two

storage hoppers for the flaked

material.

It’s only human

to want the most

for your money…

To Install In Summer

It is expected to install the

Sandvik Flaker during the summer shutdown and to have it in

operation by January 1, 1974.

Ron Sidelick is the process

engineer and Jim Gargan, installation and construction of

the new equipment and

facilities.

Naugatuck Savings Bank pays it…

Learn . . .

(Cont’d from page 2)

cost of the runs against the

counting standard for the

manufacture of a product.

Easy To Learn

The word “computer” often

frightens people, as if it were

some kind of a complicated

monster. But in reality

it is no more than an improved

calculator and serves as a time

saving tool for solving difficult

mathematical problems.

Experienced Staff

The staff of Dan O’Donnell,

Allan Mitchell, Sandra Bond,

Vin Ricci, and Dr. Dave Liu —

all have long experience in

use of computers and are

available at the center to show

you the basics in using the IBM

1130. You’ll find it is simple to

use.

“Nothing would be done at all

if a man waited till he could do

it so well that no one could find

fault with it.”

SAFETY IS MY RESPONSIBILITY

DON’T DRINK AND DRIVE

Starting Feb. 1, Payable May 1

CONTINUOUS COMPOUNDING will give…

6.27%

Effective

Annual Yield on

6.00% a year

Two Year Certificates

($1000 minimum and multiples)

5.20%

Effective

Annual Yield on

5.00% a year

Regular Savings Accounts

Yes, for the quarter beginning Feb. 1, 1973, Naugatuck

Savings Bank will compound interest continuously 365

days a year and credit the interest quarterly, beginning

May 1. Our depositors will receive the highest possible

effective annual yields at the rates allowed by law.

So if your plans call for ready cash to meet present needs,

our Regular Savings Account is better for you. If you’re

looking ahead to more distant goals, a two year certificate

is the perfect answer. You may even want both kinds of

accounts. Whichever you choose, you’ll get the most for

your money at Naugatuck Savings Bank, where the banking is human.

151 CHURCH STREET., Monday to Thursday 9-3, Friday 9-5:30

MOUNTVIEW SHOPPING PLAZA,, Monday to Wednesday and Friday 10-7, Thursday 10-7

“We make banking human.”

Naugatuck Savings Bank

—

## Page 212

Salesman Set ’73 Goal Free X-Ray CHEM-PROD JOTTINGS

Offered Employees

by 7 BUILDING CREW

These jottings on what is going on in Chemical Production is an attempt to get more information to the people in the department. Hopefully, with the ideas and suggestions of the Chemical Production Operators, we will get information on what the people in the plant want to know. So, next time you see the “7 Building Crew” give them your suggestions to improve this column.

SAFETY: We ended the year with 3 lost timers and 11 serious injuries, a total of 14 which is one more than last year. Not so good.

PRODUCTION: Business is running heavier, with most buildings on 6 days. On C-70 & 79 Building we’re working getting Polygrad and rolling in 109 Building so stations are up again.

QUALITY: The rejection rate for 1972 of 2.1% is really great. For a long time we thought 3.5% of production was good. Good Job by all.

PALLETS: We need the help of all operators. If we can do a good job separating all broken and empty pallets from the good ones (stacked up side down) the lift drivers can get them out of the way quicker to the side of the plant for repairs. We need your cooperation, otherwise these pallets just keep going round and around the buildings.

100 Building: We recently had funds approved to get rid of the old office header on the second floor and to renovate a new one for the first floor.

This should improve the housekeeping and reduce drum handling.

BIK-OT: Sales have jumped substantially in the last six months. 73 and D&G did a good job in meeting a 90,000 pound back order.

AMINOFENETANOX EXPANSION:

Recently a $375,510 was approved to expand the production of Aminox and Bretnol in 79 Building. A continuous belt Slater (known as a Sandvik Belt Flaker) will be installed to eliminate the Aminox and Bretnol granulating operation. The Sandvik Belt Flaker will greatly reduce the amount of material “picked up” from fans. Reduce manual labor, dust & fumes, a safety problem.

It is expected to install the Sandvik Flaker during the 1973 Summer Shutdown and have it operating by January 1, 1974. General Building Fume Control equipment will also be installed to improve the environment.

500 Fire Units Checked

TSSC and the Bethany Greenhouse were completely replaced to have fire extinguishers hydro statically tested for safety. The new OSHA law requires that the extinguishers be checked every five years, but the Plant Protection department goes a big step further than the federal requirements and checks them every six months for pressure, weight, seals, and if necessary, refill them with dry powder or other special material according to their contents. “Checking the extinguishers in the photo from left are Prof Sergeants, Dick Ortelle, and Ricardo Esteverribia.

Chem-Texts Page 5

Green’s

The Biggest Little Store In The Country

Visit our four floors of famous brands for him and her

Ladies’ Dept.

Costume Coats

Tanner Dresses

Vanity Fair Lingerie

Joyce-Naturlizer Shoes

Men’s Shop

Manhattan Shirts

Botany Suits-Sport Coats

H. Freeman Suits

London Fog Rainwear

Florshein Shoes

Jaymar Slacks

Lingerie Shop

Vanity Fair

Olga-Barbizoa

Schrank Robes

Shadowline

Jr. Sportswear

Georgetown Sweaters

White Stag-Skirts, Slacks

Davis Coats

Peerless Sportswear

Ski Boutique

Ski Jackets

Warm-Up Slacks

Ski Pants

Ski Sweaters

Gloves & Sweaters

Cosmetic & Jewelry Dept.

Guerlain

Elizabeth Arden

Nina-Ricci

Chanel

Yves Saint Laurent

Trifari

Napier

Tiarella Pearls

—

## Page 217

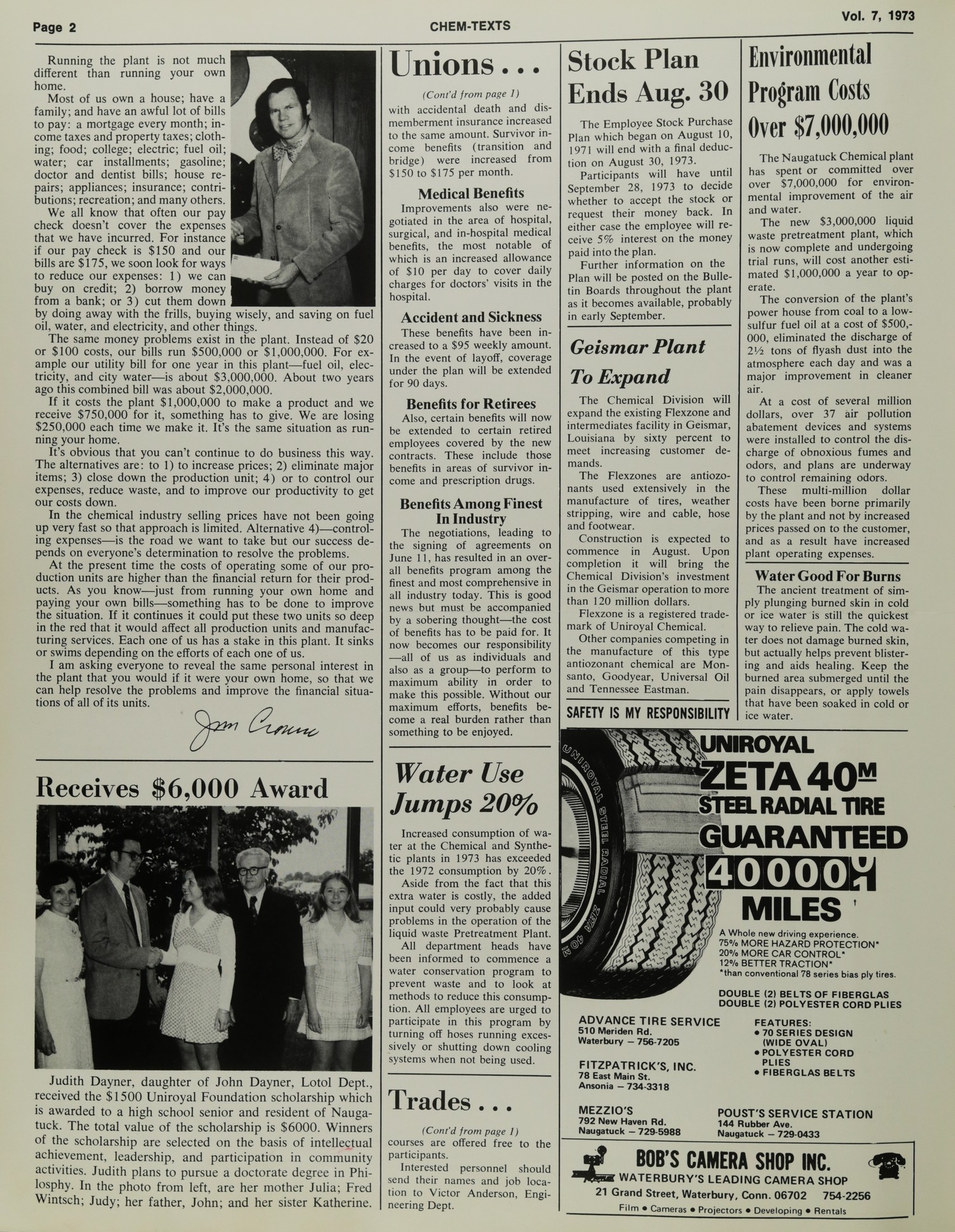

Eight Retire…

James J. Norton, Sr. retired after 35 years of service. Congratulating him here are William Rek and Gene Reale.

Mary Regan (seated) retired from R&D after 38 years service. In the photo lr-are Walter Budd, Carolyn Guerra, Martha Rawinski, Mary Regan, Jeanine Lebrecque, Barbara Robinson, and Anna Kavalukas.

Francis Giedraitis, a Synthetic Storehouse Group Leader, retired after 17 years. Congratulating him here are Kenneth Nelson, Gertrude, George Chipko and Clayton Housenecht.

John Kankel (right), retired from the Materials & Quality Control department after 26 years service. With him are (lr) Fernando Gagne, Daniel Gengo and Kenneth Paul Torricelli, and Dominic Polzella.

Vernon Anderson, right, retired from the Industrial department after 40 years service. Congratulating him are W. Joseph Beredski, John Cella and Anderson (G. Allen photo).

Paracril Production Increased

A second crew has been added to the Finishing department at the Synthetic Plant in order to run two shifts for the rest of 1973 depending on the availability of acrylonitrile. The extra crew is required to manufacture the overflow business in Paracril which rather other division plants.

At present it is not known if this increased Paracril business will be extended beyond the end of 1973.

Paracril is an oil resistant type of synthetic rubber and is used extensively in electrical wire and cable, fuel hose, automotive applications, and in work shoes.

Wisconsin Tire Plant Expands

The Uniroyal Tire Company, now ranked the largest supplier of steel belted radial ply passenger tires to the U.S. automotive industry, will make an all-steel radial ply heavy service tire in the U.S.

A $24 million expansion program is now underway at the East Claire, Wisconsin tire plant to produce mono-ply steel belted radial heavy service tires primarily for tractor-trailer trucks. The plant will make 250 tires a day by the end of 1974 and if the tires are successful large scale production will start before 1976.

The expansion will create 40 jobs at the plant and add about $500,000 to the payroll.

Joseph Mays, left, is congratulated by William Hill on his retirement after 30 years service.

“What AA Has Done For Me”

This story was written by an employee who had a drinking problem and joined AA. Since it is the policy of AA to remain anonymous he requested that his name be withheld from the article, the third in a series.

For the last ten years AA has transformed my life from one of drunkeness, resentments and guilt to one of sobriety, new found freedom. It feels good saying good-bye to that first drink one day at a time and reaching the point where we wouldn’t have it any other way. There is so much more to life than what we make of it. We are free to choose. Everyday I choose not to drink because I know if I did I would lose that freedom. I would go be enslaved to a bottle. Life in AA is a lot more than just staying away from that first drink and thereby staying sober. It is a whole new way of life. The fellowship in the program is a constant reminder that we are not alone. Everywhere we go any day of the week we know there is a group of people who will accept us, understand us and help us if we need it. This is like total security.

The AA program is built on core steps which we go through and continue to repeat. These steps help us to grow spiritually as a group and also the homeless drunks, men and women who have “gotten it all together.”

For the the biggest change has been in my relationships with people. When I was drinking I used to feel a lot of anger and hostility toward a lot of people, especially toward myself. Now I am really free from all of that kind of feeling. There is a lot of love and a lot of joy in my life thanks to AA.

Anyone interested in learning more about AA can call 753-0185 at any time.

Social Security Assistance

Employees who are planning to retire and apply for social security benefits can obtain assistance in filing out the necessary application forms by calling George Allen in the Industrial Relations department, Ext. 217.

An application for social security benefits should be filed at least three months prior to retirement so that benefit payments will begin with the effective date of retirement.

A social security office is located at 232 Grand Street in Waterbury.

Chittenden Insurance Agency, Inc.

Insurance–Mutual Funds–Real Estate

180 Church Street

Naugatuck, Connecticut

Tel. 729-8209

Frederick D. Zonino Nathan M. Pierpont, Jr.

PUBLISHED BY THE INDUSTRIAL RELATIONS DEPARTMENT

UNIROYAL CHEMICAL, NAUGATUCK, CONN. 06770

EDITOR: William F. Lavelle.

Jobs To Be Reposted

The old job postings for positions in the new $1,000,000 Liquid Waste Pretreatment plant will be posted again on March 1, 1974 for one week. The jobs will be awarded on March 1, 1974, according to tentative plans. It was announced by Aldo Manzi, Superintendent of Engineering. Present plans indicate that 5 positions will be available in the new facility.

STOCKS BONDS MUTUAL FUNDS

HERITAGE VILLAGE FINANCIAL CENTER

SOUTHBURY, CONNECTICUT 06488

ARTHUR THOMAS, JR. Manager

TELEPHONE 264-6511

EDWARD H. MITCHAM, JR.

—

## Page 219

Running the plant is not much different than running your own home. Most of us own a house; have a family; and have an awful lot of bills to pay: a mortgage every month; insurance; taxes; telephone; food; college; electric; fuel oil; water; car installments; appliance repairs; doctor and dentist bills; house repairs; appliances; institutions; contributions; recreation; and many others. We all know that our pay check doesn’t cover the expenses that we have incurred. For instance if our pay check is $150 and our bills are $175, we soon look for ways to supplement that pay check: 1) buy on credit; 2) borrow money from a bank; or 3) cut them down by doing away with the frills, buying wisely, and saving on fuel oil, water, and electricity, and other things.

The same money problems exist in the plant. Instead of $20 or $100 costs, our bills run $50,000.00 or $1,000,000. For example our utility bill for one year in this plant—fuel oil, electricity, and water—is about $5,000,000. About two years ago it was about $2,000,000.

If it costs the plant $1,000,000 to make a product and we receive $250,000 each time we make it. It’s the same situation as running your own home.

It’s obvious that you can’t continue to do business this way. The alternatives are: 1) to increase sales, 2) eliminate major items; 3) close down the production unit; 4) or to control our expenses, reduce waste, and to improve our productivity to get our costs down.

In the chemical industry selling prices have not been going up as rapidly as our costs of manufacturing have been. To maintain our industry selling prices is limited, the alternative is to control the expenses—is the road we want to take but our success depends on everyone’s determination to resolve the problems.

At the present time the costs of operating some of our production units are higher than the financial return for their products. As you know—just from running your own home and paying your own bills—something has to be done to improve the situation. If it continues it could put these two units so deep in the red that it would affect all production units and manufacture throughout the country. The future of the plant and of the industry hangs in the balance, is up to us, either to win or to lose depending on the efforts of each one of us.

I am asking everyone to reveal the same personal interest in the plant that you would if it were your own home, so that we can help resolve the problems and improve the financial situations of all of its units.

Unions… Stock Plan Ends Aug. 30

(Cont’d from page 1)

with accidental death and dismemberment insurance increased from $10,000 to $15,000. Survivor insurance benefits (transition and bridge) increased from $150 to $175 per month.

Medical Benefits

Improvements also were medical, surgical, and in-hospital medical benefits, the most notable of which is an increased allowance of $10 per day to cover daily charges for doctors’ visits in the hospital.

Accident and Sickness

These benefits have been increased to a $95.00 weekly amount. In the event of longer coverage under the plan will be extended to 42 days.

Benefits for Retirees

Also, certain benefits will now be extended to certain retired employees in accordance with the terms of their contracts. These include those benefits in force at the time of retirement, including life and prescription drugs.

Benefits Among Finest

The negotiations, leading to the signing of agreements on June 11, 1973 resulted in an excellent benefit package for the Naugatuck Division employees. This is good news but must be accompanied by a sobering thought—the cost of benefits has risen to the point that no company can afford to make this a responsibility of all of us as individuals and also as a group to perform to maximum performance to make this possible. With our maximum efforts, benefits become a real burden rather than something to be enjoyed.

Environmental Program Costs Over $7,000,000

The Naugatuck Chemical plant has spent or committed over $7,000,000 for environmental improvement of the air and water.

The new $3,600,000 plant, which is a major investment in eliminating stack emissions and final runs, will cost another estimated $1,000,000 a year to operate.

The conversion of the plant’s power house from coal to a lower sulfur fuel oil at a cost of $500,000, eliminated the discharge of 215 tons of flyash dust into the atmosphere each day and was a major improvement in cleaning the air.

At a cost of several million dollars, over 27% of pollution abatement devices and systems were installed to control the discharge of obnoxious fumes and odors, and pans are underway to control remaining odors. These million dollar expenditures have been borne primarily by the plant and not by increase in product costs to consumers.

Water Good For Burns

The ancient treatment of simply plunging burned skin in cold or ice water is still the quickest way to relieve pain. The cold water actually helps prevent blistering and aids healing. Keep the burned area submerged until the pain disappears, or apply towels that have been soaked in cold or ice water.

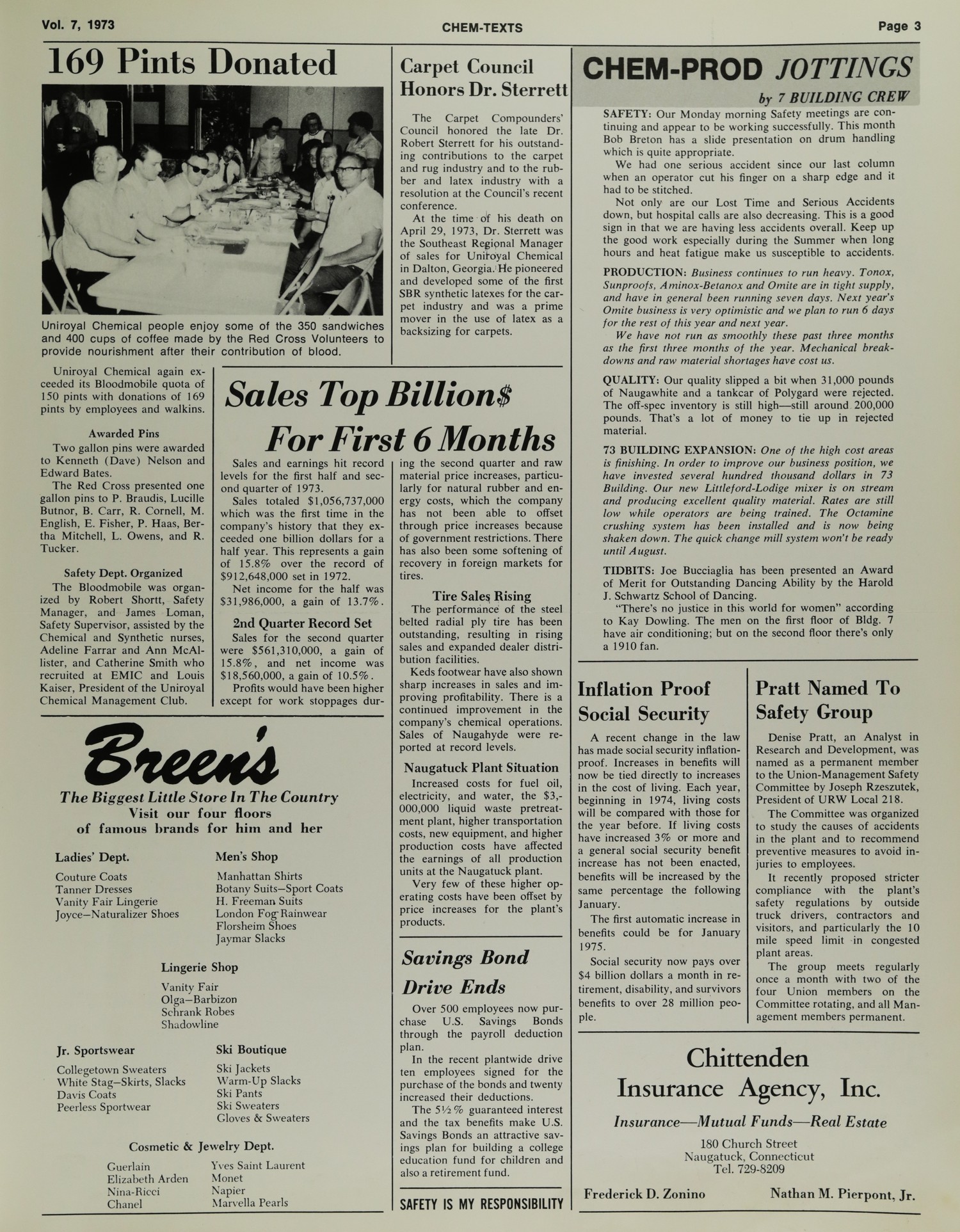

Receives $6,000 Award

Judith Dayner, daughter of John Dayner, Lold Dept., received the $1,500 Uniroyal Foundation scholarship which is awarded to a high school senior and resident of Naugatuck. The total value of the scholarship is $6,000. Winners of the scholarship are selected on the basis of intellectual achievement, leadership, and participation in community activities. Judith plans to pursue a doctorate degree in Philosophy. In the photo from left, are her mother Judith; Judy; her father, John; and her sister Katherine.

Geismar Plant To Expand

The Chemical Division will expand existing Flexzone and intermediates facility in Geismar, Louisiana to study planned to meet increasing customer demands.

The Flexzones are antioxidants used extensively in the manufacture of automobile tires, weatherstripping, wire and cable, hose and footwear.

Construction is expected to commence in August. Upon completion it will bring the Chemical Division’s investment in the Geismar operation to more than $12 million dollars.

SAFETY IS MY RESPONSIBILITY

UNIROYAL ZETA 40M STEEL RADIAL TIRE GUARANTEED 40,000 MILES

A Whole new driving experience. 75% MORE HAZARD PROTECTION*. 20% MORE CORNERING AND BRAKING TRACTION* than conventional tires.

DOUBLE (1) BELTS OF FIBERGLAS DOUBLE (2) POLYESTER CORD PLIES

ADVANCE TIRE SERVICE

510 Meriden Rd. – Waterbury – 756-7205

FITZPATRICK’S, INC.

6 East Main St., Waterbury – 734-3318

MEZZIO’S POUST’S SERVICE STATION

792 New Haven Rd. 144 Rubber Ave.,

Naugatuck – 729-0888 Naugatuck – 729-0433

BOB’S CAMERA SHOP INC.

WATERBURY’S LEADING CAMERA SHOP

69 Grand Street, Waterbury, Conn. 06702 – 754-5256

Film • Cameras • Projectors • Developing • Rentals

Trades…

(Cont’d from page 1)

courses are offered free to the participants.

Interested personnel should send their names and job location to Victor Anderson, Engineering Dept.

Water Use Jumps 20%

Increased consumption of water at the Chemical and Synthetic plants in 1973 has exceeded the 1972 consumption by 20%. Aside from the fact that the extra water is costly, the added input could very probably cause overload and reduce the effectiveness of the Liquid Waste Pretreatment Plant. All departments have been informed to commence a water conservation program to prevent waste and to look at methods to reduce this consumption. All employees are urged to participate in this program by turning off hoses running excessively or shutting down cooling towers when not being used.

—

## Page 220

Vol. 7, 1973

CHEM-TEXTS Page 3

169 Pints Donated

Carpet Council

Honors Dr. Sterrett

The Carpet Compounders’

Council honored the late Dr.

Robert Sterrett for his outstanding contributions to the carpet

and rug industry and to the rubber and latex industry with a

memorial conference.

At the time of his death on

April 29, 1973, Dr. Sterrett was

the Southeast Regional Manager

of sales for Uniroyal Chemical

in Dalton, Georgia. He pioneered

and developed some of the first

SBR synthetic latices for the carpet industry and was a prime

mover in the use of latex as

backings for carpets.

Uniroyal Chemical people enjoy some of the 350 sandwiches

and 400 cups of coffee made by the Red Cross Volunteers to

provide nourishment after their contribution of blood.

Uniroyal Chemical again exceeded its Bloodmobile quota of

150 pints with donations of 169

pints by employees and visitors.

Awarded Pins

Two gallon pins were awarded

to Kenneth (Dave) Nelson and

Glenna Gannon.

The Red Cross presented one

gallon pins to B. Brattin, Lucille

Buthor, B. Carr, E. Cornell, M.

Fitcher, L. Fisher, B. Harris, Barbara Mitchell, L. Owens, and R.

Tucker.

Safety Dept. Organized

The Bloodmobile was organized by Robert Sterrett, Safety

Supervisor, assisted by the

Chemical and Synthetic nurses:

Adeline Farrar and Ann McAllister, and Catherine Smith who

recruited at EMC and Louis

Graper, President of the Uniroyal

Chemical Management Club.

CHEM-PROD JOTTINGS

by 7 BUILDING CREW

SAFETY: On Monday morning Safety meetings are continuing and appear to be working successfully. This month

Bob Breton has a slide presentation on drum handling

which is quite appropriate since we have had a serious accident this month when an operator had his finger cut when

he had to be stitched.

Not only are our Lost Time and Serious Accidents

down, but hospital calls are also decreasing. This is a good

sign in that we are having less accidents overall. Keep up

the good work especially during the Summer when long

hours and heat fatigue make us susceptible to accidents.

PRODUCTION: Business continues to run heavy. Tonox,

Suprapol’s, Aminox-Bellnox and Omite are in tight supply,

and have in general been running seven days. Next year

Omite business is very optimistic and we plan to run 6 days

for the rest of this year and next year.

We have not run as smoothly these past three months

as in the first three months of the year. Mechanical breakdowns and process material shortages are the major problems.

QUALITY: Our quality shipped is also up when 31,000 pounds

of Naugawhite and a tanker of Polygrad were rejected.

The off-spec inventory is still high—still around 400,000

pounds. That’s a lot of money to tie up in rejected

material.

73 BUILDING EXPANSION: One of the high cost areas

is Building 73, in order to improve our position, we

have invested several hundred thousand dollars in 73

Building. Our new Linear-Low-Density unit is on stream,

and the new packaging system has been installed. Our quality is

low while operators are being trained. The Oeniniline

cracking system has been installed and is now being

shaken down. The quick change mill system won’t be ready

until August.

Sales Top Billions$

For First 6 Months

Sales and earnings for record

levels for the half and second quarter of 1973.

Net income for the half was

$31,986,000, a gain of 13.7%.

2nd Quarter Record Set

Sales for the second quarter

were $561,310,000, a gain of

15.8%, and net income was

$18,560,000, a gain of 10.5%.

Profits would have been higher

except for work stoppages dur-

$912,648,000 an all time record for 1972.

Net income for the half was

$31,986,000, a gain of 13.7%.

The performance of the steel

belted radial ply tire has been

outstanding, resulting in rising

sales and expanded dealer distribution facilities.

Keds footwear have also shown

sharp increases in sales and improvement in the company’s

combined chemical operations.

Sales of Naugalyde were reported at record levels.

Naugatuok Plant Situation

Increased costs for fuel oil,

electricity, and water, the 5%

payroll increase, and an equipment plant, higher transportation

costs, and equipment, and higher

production costs have affected

the earnings of all production

units at the Naugatuok plant.

Very few of these higher operating costs have been offset by

price increases for the plant’s

products.

Savings Bond

Drive Ends

Over 500 employees now purchase U.S. Savings Bonds

through the payroll deduction

plan.

In the recent plantwide drive

ten employees signed for the

purchase of the bonds and thereby

increased their deductions.

The 5½% guaranteed interest

and the tax benefits make U.S.

Savings Bonds an attractive savings plan for building a college

education fund for children and

also a retirement fund.

SAFETY IS MY RESPONSIBILITY

TIDBITS: Joe Buccigalia has been presented an Award

of Merit for Outstanding Dancing Ability by the Harold

J. Schwartz School of Dancing.

“There’s no justice in this world for women” according

to Kay Dowling. The men on the first floor of Bldg. 4

have air conditioning; but on the second floor there’s only

a 1910 fan.

Inflation Proof

Social Security

A recent change in the law

has made social security inflationproof. Increases in benefits will

now be tied directly to increases

in the cost of living. Each year,

beginning in 1974, living costs

will be compared with those for

the year before. If living costs

have increased 3% or more and

a general social security benefit

increase has been enacted, the

benefits will be increased by the

same percentage the following

January.

The first automatic increase in

benefits could be for January

1975.

Social security now pays over

$4 billion dollars a month in retirement, disability, and survivors

benefits to over 28 million people.

Chittenden

Insurance Agency, Inc.

Insurance—Mutual Funds—Real Estate

180 Church Street

Naugatuck, Connecticut

Tel. 729-8209

Frederick D. Zonino Nathan M. Pierpont, Jr.

Pratt Named To

Safety Group

Denise Pratt, an Analyst in

Research and Development, was

named as a permanent member

to the Union-Management Safety

Committee by Joseph Reszutek,

President of URW Local 218.

The Committee was organized

to study the causes of accidents

in the plant and to recommend

preventive measures to avoid injuries.

It recently proposed stricter

compliance with the plant’s

safety regulations by outside

truck drivers, contractors and

visitors, and particularly the 10

mile speed limit in congested

plant areas.

The group meets regularly

once a month with two of the

four Union members on the

Committee relating, and the Management members permanent.

—