## Page 002

Page 2

CHEM-TEXTS Vol. 13 1979

Professional Excellence

The Parcel Post Department is an example of a group of individuals who have demonstrated Professional Excellence in the performance of their jobs. Jessie DaSilva, Jim Harnett, Frank Rubia (Group Leader), and Joe Wojczak (Foreman) have a reputation of expertly preparing and shipping samples of our products to all parts of the U.S. and the world. This function is extremely important in obtaining new business since it is the first impression that our customers receive of our ability to service their needs.

The Group exercises responsibility and initiative and demonstrates a positive attitude in “helping others.” They have a professional expertise in packaging techniques that are unequaled.

They display a professional knowledge of Federal regulations regarding the shipping of hazardous materials and the regulations concerning the air shipment of hazardous materials.

Some of the innovations that the members of the Department introduced were: Jessie DaSilva instituted the use of cellular polyfoam pellets to be used as a cushion material in packaging samples for rough handling. The pellets, which are produced by Mechanical Stores, are made here at the Lab, replace the use of a polyethylene bubble film which was purchased to protect the samples in transit. Not only did this suggestion improve our package, but it eliminated the cost of the bubble film.

James Harnett instituted an inventory system of all materials handled by the Parcel Post Department. This system promptly enables him to know if he has approved material needed for the sample shipment.

Jim has also devised with the group a warehousing system for the storage of larger quantities of material that have to be replenished into smaller units for samples. Both of these systems display the progressiveness of the group by enabling the Parcel Post group to ship material on time and feed back information to the Customer Service group when needed.

Jim has also organized a tagging system to enable material to be sent from all points in the plant, including Bethany, to the Parcel Post Department with the necessary information attached to the package to expedite shipment of that package.

Francis P. Rubia set up a sample book of all necessary Parcel Post paperwork that is needed to go along with any shipment. This has become a learning tool for trainees, and also a guide in the handling of shipments by experienced employees.

Robert Clark, a former Department member, and Francis Rubia, set up a filing system on all orders shipped from the Parcel Post Department. It is arranged alphabetically by customer’s name for expediting and tracking samples.

It is this kind of professionalism and excellence in the performance of our responsibilities that has helped improve our plant’s performance and made it the flagship of the chemical division.

We all appreciate the professional expertise the Parcel Post Department and offer our thanks.

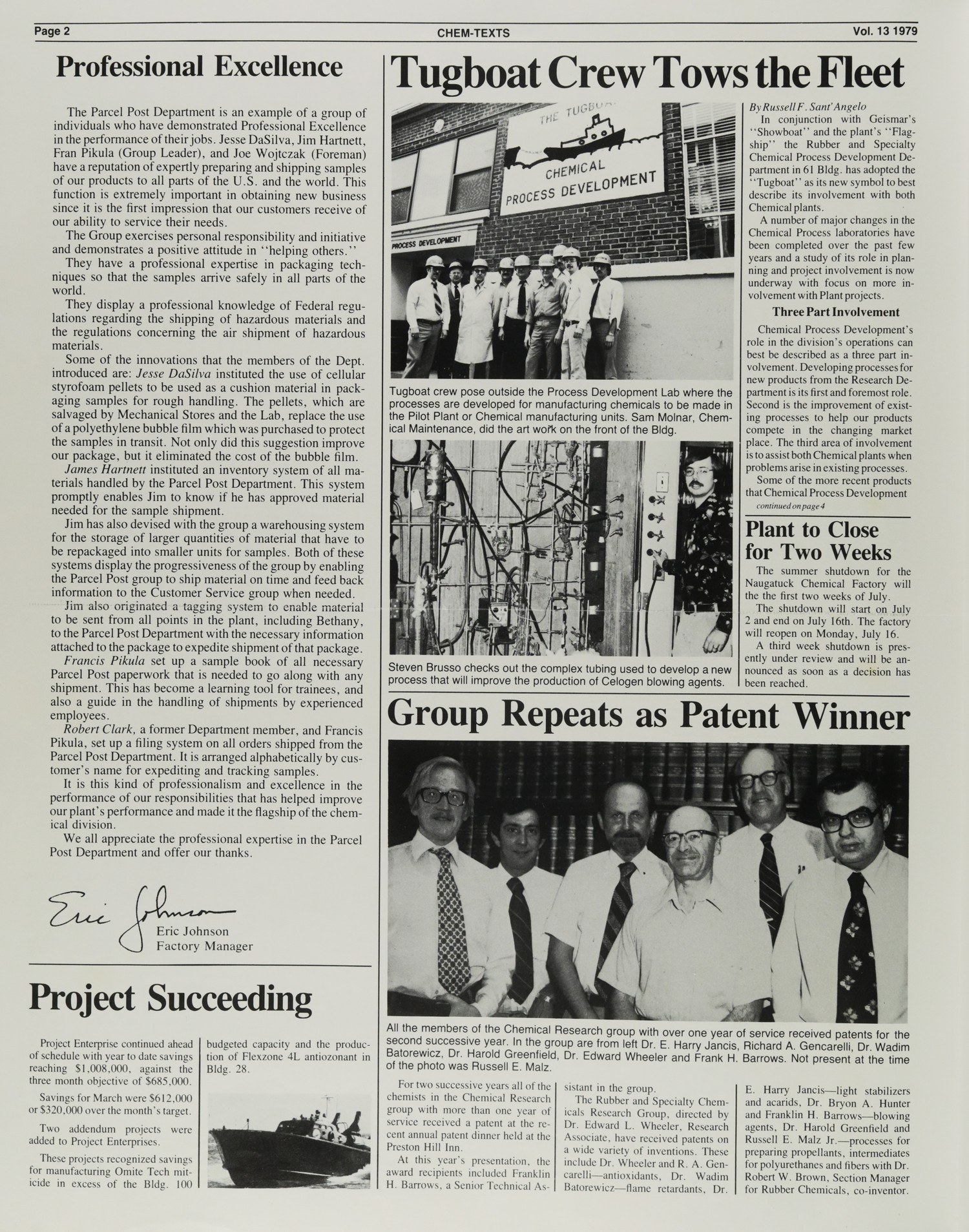

Tugboat Crew Tows the Fleet

In conjunction with Gesmar’s “Tugboat” and the plant’s “Fire ship” the Rubber and Specialty Chemicals Process Development Department on Bldg 28, has adopted the “Tugboat” as its new symbol to best describe its involvement with both Chemical Plants.

Three Part Involvement

The Chemical Process Development’s role in the division’s operations can best be described as a three part involvement. Developing processes for new products from the Research Development Department is its first and foremost role. Second is the improvement of existing processes to compete in the changing market place. The third area of involvement is to assist both Chemical plants when problems arise in existing processes.

Some of the more recent products that Chemical Process Development has completed over the past few years and a study of its role in planning and project involvement is now underway with focus on more involvement with Plant projects.

Plant to Close for Two Weeks

The summer shutdown for the Niagara Chemical Factory will be the first two weeks of July. The shutdown will start on July 2 and end on July 16th. The Factory will reopen on Monday, July 16.

A third week shutdown is presently under review and will be announced as soon as a decision has been reached.

Group Repeats as Patent Winner

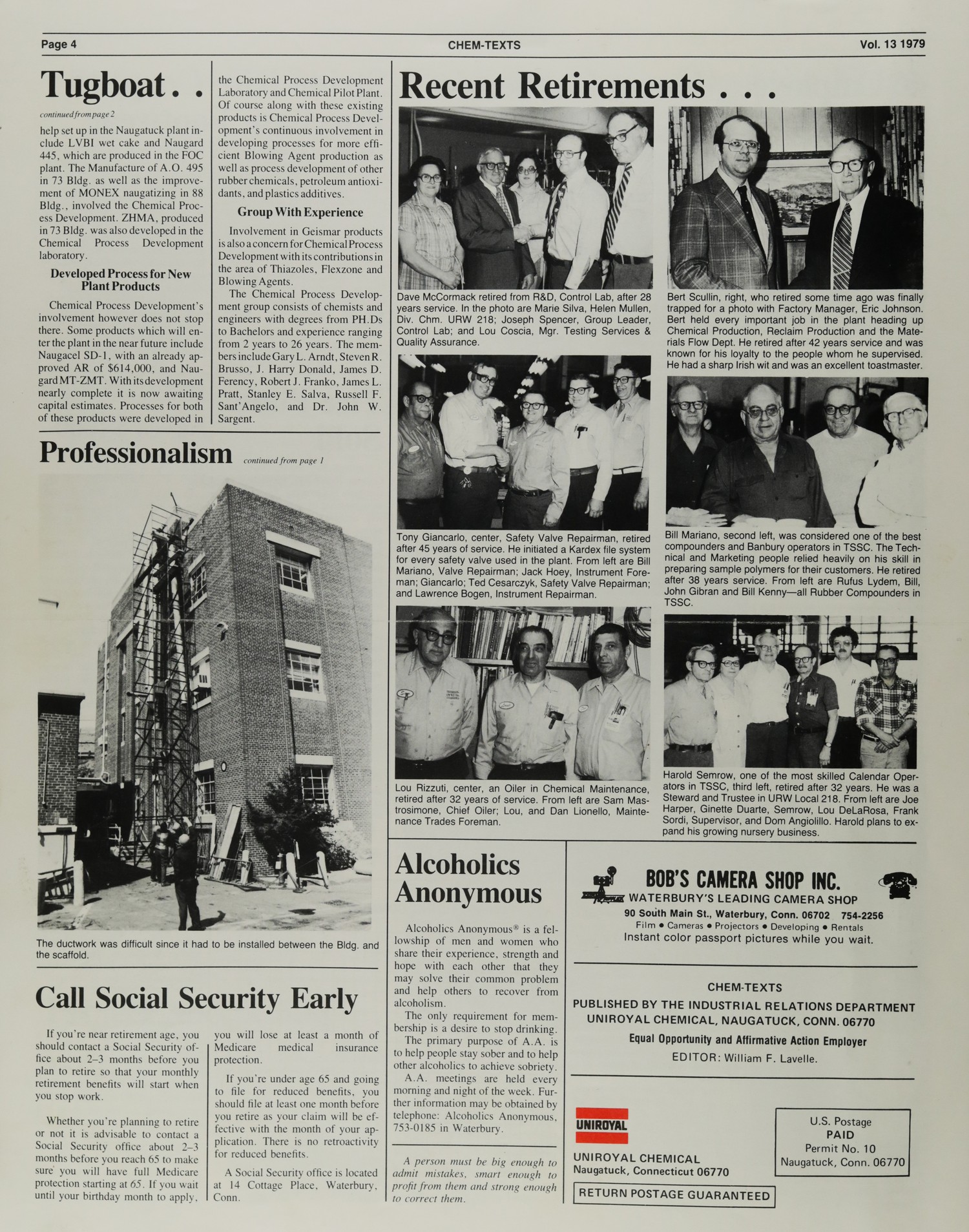

All the members of the Chemical Research group with over one year of service received patents for the second successive year. In the group are from left: Dr. E. Harry Jancis, Richard A. Gerraraidi, Dr. Wadim Raltkowich, Dr. Harold Greenfield, Dr. Edward L. Wheeler, Research Associates, have received patents on a wide variety of inventions. These include Dr. Wheeler and R. A. Gerraraidi–antioxidants, Dr. Wadim Raltkowich–flame retardants, Dr. Edward L. Wheeler, process for preparing propellants, intermediates for polyurethanes and others, with Robert W. Brown, Section Manager for Rubber Chemicals, co-inventor.

—

## Page 004

Tugboat . . .

the Chemical Process Development Laboratory and Chemical Pilot Plant. Of course, along with these existing products is Chemical Process Development’s continuous involvement in developing processes for more efficient Blowing Agent production as well as process development of other rubber chemicals, petroleum additives, and plastics additives.

Group With Experience

Involvement in Gessmar products is also a concern for Chemical Process Development with its contributions in the area of Thiazoles, Flexzone and Blowing Agents.

Developed Process for New Plant Products

Chemical Process Development’s involvement however does not stop there. Some notable projects for the plant in the near future include Naugatuck SH-1, with an already approved AW of $614,000, and Naugatuck MT-2MT with development nearly complete is now awaiting capital estimates. Processes for both of these products were developed in the Chemical Process Development laboratory.

Professionalism (continued from page 1)

The clockwork was difficult since it had to be installed between the Bldg. and the scaffold.

Call Social Security Early

If you’re near retirement age, you should contact a Social Security office about 2-3 months before your birthday to discuss your plan to retire so that your monthly retirement benefits will start when you stop work.

Whether you’re planning to retire or not it is advisable to contact a Social Security office about 2-3 months before your 65th birthday. Medicaid protection is also starting at 65. If you wait until your birthday month to apply, there is no guarantee your Medicaid protection will start then.

Recent Retirements . . .

Dave McCormack retired from R&D, Control Lab, after 28 years service. In the photo are Marie Sailo, Helen Mullen, Dr. Chin, LSOV 215, Joseph Sosnicki, Group Leader, Factory, Quality Assurance.

Tony Giancarlo, center, Safety Valve Repairman, retired after 35 years of service. He initiated a Kardex file system for every safety valve used in the plant. From left are Bill Marino, Valve Repairman; Jack Hoey, Instrument Foreman; and Lawrence Bogen, Instrument Repairman.

Lou Rizzuti, center, an Oiler in Chemical Maintenance, retired after 32 years of service. From left are Sam Mastroianni, Operator; Chief Oiler Lou; and Dan Lionello, Maintenance Trade Foreman.

Alcoholics Anonymous

Alcoholics Anonymous* is a fellowship of men and women who share their experience, strength and hope with each other that they may solve their common problem and help others to recover from alcoholism.

The only requirement for membership is a desire to stop drinking.

The primary purpose of A.A. is to help problem drinkers sober and to help other alcoholics to achieve sobriety. A.A. meetings are held every morning and night of the week. For information you can telephone: Alcoholics Anonymous, 753-0185, in Waterbury.

A person must be sober enough to attend meetings, smart enough to profit from them and strong enough to contribute to the group.

BOB’S CAMERA SHOP INC.

WATERBURY’S LEADING CAMERA SHOP

60 South Main St., Waterbury, Conn. 06702 754-2256

Film • Cameras • Projectors • Developing • Rentals

Instant color passport pictures while you wait.

PUBLISHED BY THE INDUSTRIAL RELATIONS DEPARTMENT

UNIROYAL CHEMICAL, NAUGATUCK, CONN. 06770

Equal Opportunity and Affirmative Action Employer

EDITOR: William E. Lavelle

U.S. Postage

PAID

Naugatuck, Conn. 06770

Permit No. 10

UNIROYAL CHEMICAL

NAUGATUCK, CONNECTICUT 06770

RETURN POSTAGE GUARANTEED

—

## Page 013

Omite Tops Goal by 40%

by Norm Boisseau

Because of the cooperation, expertise and diligent efforts of the Bldg. 100 OMITE operators, the plant achieved an exceptionally challenging goal of producing 3.9 million lbs. of OMITE for the 1979 season which ended on 8.1.79.

The diligent efforts of the Technical, Maintenance and Material Handling personnel who manufacture the CMO intermediate also contributed greatly to this record. The whole plant in reality should be recognized for this accomplishment.

This was accomplished by exceeding the 1979 Productivity Standard by OVER 40% on a Y-T-D basis.

Gov. Grasso . . .

After the brief addresses by the guests Gov. Grasso cut the Flag-ship case. Coffec and cake was served in a huge 30 ft. x 90 ft. tent which contained displays of directives, and chemical products manufactured in the plant.

The entire event was telcast on Channel 13 TV News and broadcast on WCCO, WATR, and WNVR.

75 Years…

In August of 1955 the Naugatuck River devastated the plant. The flood waters covered the first floor of Bldg. 7.

Flagship of Division

In spite of its geographic distance from the source of raw materials it has maintained a competitive edge by the resourcefulness and professionalism of its people. Today the Chemical plant is recognized as the flagship of the Naugatuck Division. This is a tribute to the skills and efforts of its people.

10 Uniroyal Scholarships Offered

Ten Uniroyal Merit Scholarships will be offered to children of Uniroyal employees who have more than 5 years of continuous service as of the date of the award. All children of Uniroyal employees, who have more than 5 years of continuous service as of the date of the award, are eligible for the scholarships.

Application Must Be Filed for Scholarships

Applications for the 1981 scholarships must be submitted by November 30, 1979. They can be obtained from the Industrial Relations Dept. along with a folder which gives complete details on the scholarships. Call Constance Antman, Ext. 3217.

Students who wish to apply for a scholarship must do so during a senior high school year by taking the Preliminary Scholastic Aptitude and National Merit Scholarship Qualifying Tests which are usually given in October by the high school. Students should check the school office for the dates of the tests.

Awards Up To $1500 Yearly

The maximum amount of the award is $1500 each year during the four years of college. The amount depends on the family’s financial circumstances and the cost of the school. The minimum amount of $250.

This was the main entrance “lobby” to the plant in 1945.

—

## Page 273

Here is the text extracted from the document image, preserving the layout and structure as much as possible:

Editorial . . .

As many of you already know, this is our 75th year as a Chemical Plant as well as a Chemical Company. Today we can be proud of the fact that virtually every automobile and truck tire on the road contains one of the rubber chemicals manufactured in our plant. Our Agricultural Chemicals are used throughout the U.S. and the world to protect cotton, fruit, and other valuable food crops against disease and devastating insects. This enables farmers and growers to increase the yields of their land.

We are very grateful to both present and past employees who made this occasion possible through their achievements. We now have an even greater responsibility in performing our jobs. Your dedication and efforts must make our jobs more meaningful, secure, and safe not only for ourselves but also for those who will follow us.

Through the skills, spirit, and professional excellence that you demonstrated in 1979, the foundation has been built for even greater achievements in the future.

I wish to thank each and every one of you for making the celebration of our 75th Anniversary such a memorable and successful day. It was evidence of the good spirit that makes our plant an excellent place to be.

Eric Johnson

Factory Manager

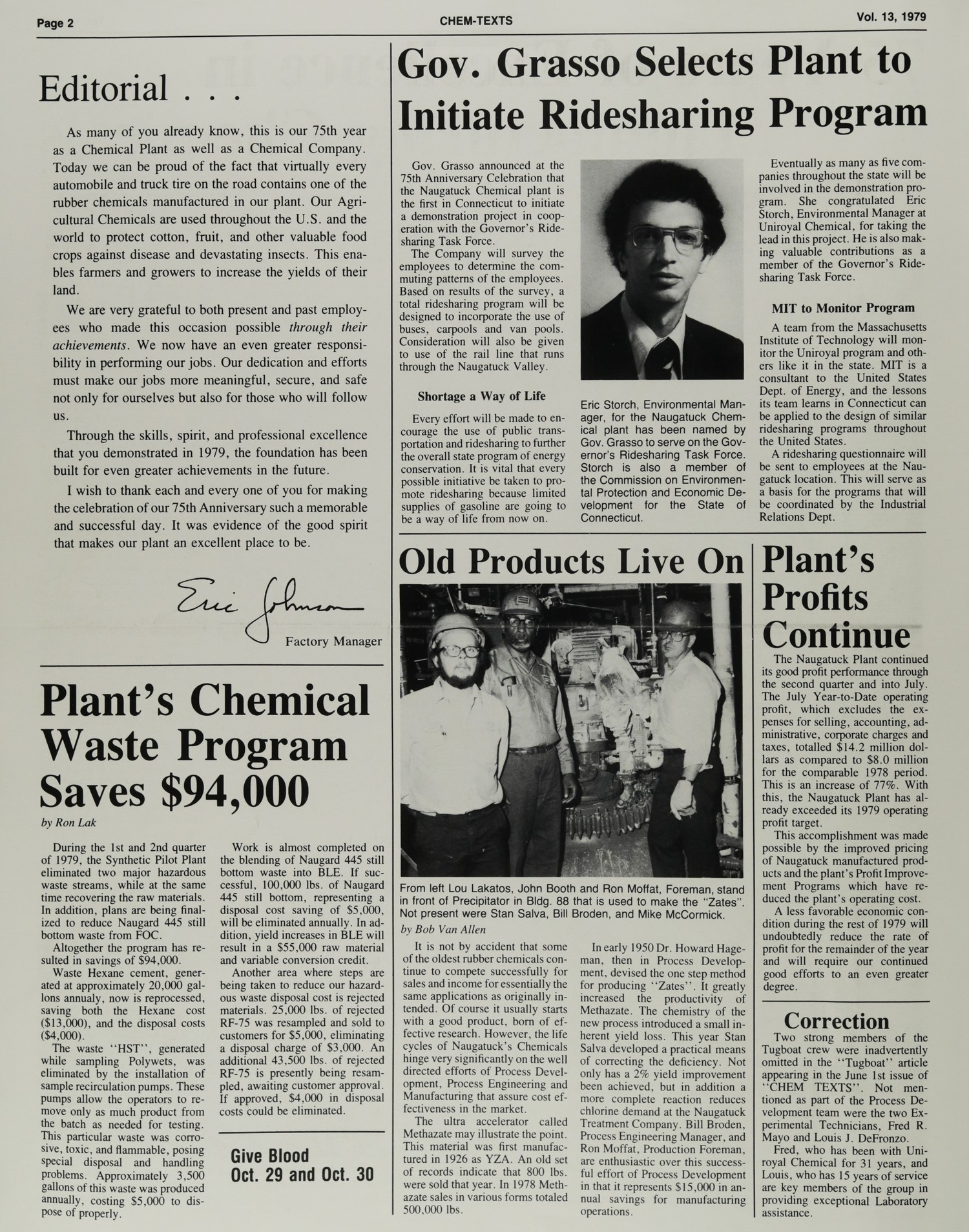

Gov. Grasso Selects Plant to Initiate Ridesharing Program

Gov. Grasso announced at the 75th Anniversary Celebration that the Naugatuck Chemical Plant is to be the first in Connecticut to initiate a demonstration project in cooperation with the Governor’s Ridesharing Task Force.

The Company will survey the employees to determine the commuting patterns of the employees. Based on results of the survey, a system will be designed to incorporate the use of buses, carpools and van pools. Consideration will also be given to use of the rail line that runs through the Naugatuck Valley.

Shortage a Way of Life

Every effort will be made to encourage the use of public transportation. This is vital that every possible initiative be taken to promote ridesharing because limited supplies of gasoline are going to be a way of life from now on.

Old Products Live On Plant’s

Profits Continue

The Naugatuck Plant continued its good profit performance through the second quarter and into July. Profit for the quarter was $4.2 million, excluding the expenses for selling, accounting, administrative, corporate charges and taxes, totaled $14.2 million dollars as compared to $8.0 million for the comparable 1978 period.

This is an increase of 77%. With this, the Naugatuck Plant has already exceeded its 1979 operating profit targets. These profits were made possible by the improved pricing of Naugatuck manufactured products and the plant’s Profit Improvement Programs which have reduced the plant’s operating cost.

A less favorable economic condition during the rest of 1979 will undoubtedly reduce the profit trend, but improved operating efficiencies and cost control will continue to some degree.

Plant’s Chemical

Waste Program

Saves $94,000

by Ron Lak

During the 1st and 2nd quarter of 1979, the Synthetic Pilot Plant eliminated two major hazardous waste streams, while at the same time recovering the raw materials.

In addition, plans are being finalized to reduce Naugatuck 445 still bottom waste from BLE to $35,000 annually. This will be eliminated annually. In addition, yield increases in BLE will reduce the 515,000 lbs. of hazardous and variable conversion credit.

Another major steps are being taken to reduce our hazardous waste disposal cost is expected to materials. 25,000 lbs. of rejected R-75 are reconditioned and sold to customers for $5,000, eliminating the disposal of $3,000. An additional 15,000 lbs. of R-75 is presently being reclaimed, awaiting customer approval. If approved, $4,000 in disposal costs could be eliminated.

The work so far, “HST”, generated an estimated Polyelene recovery, has eliminated 25% of the original samples tests. These pumps allow the operators to recover only as much product from the batch as needed for testing.

This particular waste was corrosive, toxic, and flammable, posing special disposal and handling problems. Approximately 3,500 gallons of this waste was produced annually at a disposal cost of $3,000 to dispose of properly.

Give Blood

Oct. 29 and Oct. 30

Plant to

Initiate Ridesharing Program

Eric Slorch, Environmental Manager, for the Naugatuck Chemical Plant, has been named by the Governor to serve on the Governor’s Ridesharing Task Force.

Slorch is also a member of the Commission on Environmental Protection and Economic De-velopment for the State of Connecticut.

A team from the Massachusetts Institute of Technology will monitor the Naugatuck Plant to determine the feasibility and cost effectiveness of ridesharing programs throughout the United States.

A ridesharing questionnaire will be sent to employees at the Naugatuck location. This will serve as a basis for the programs that will be coordinated by the Industrial Relations Dept.

Correction

Two strong members of the Upkeep crew were inadvertently omitted from the “Upkeep” article appearing in the June 14 issue of Chem-Texts. Fred R. Mayo and Louis J. DeFranco, Fred, who has been with Uniroyal Chemical for 15 years, and Louis, who has 15 years of service in the group, also made exceptional contributions as Experimental Technicians. Fred R. Mayo and Louis J. DeFranco provided outstanding assistance.

—

## Page 278

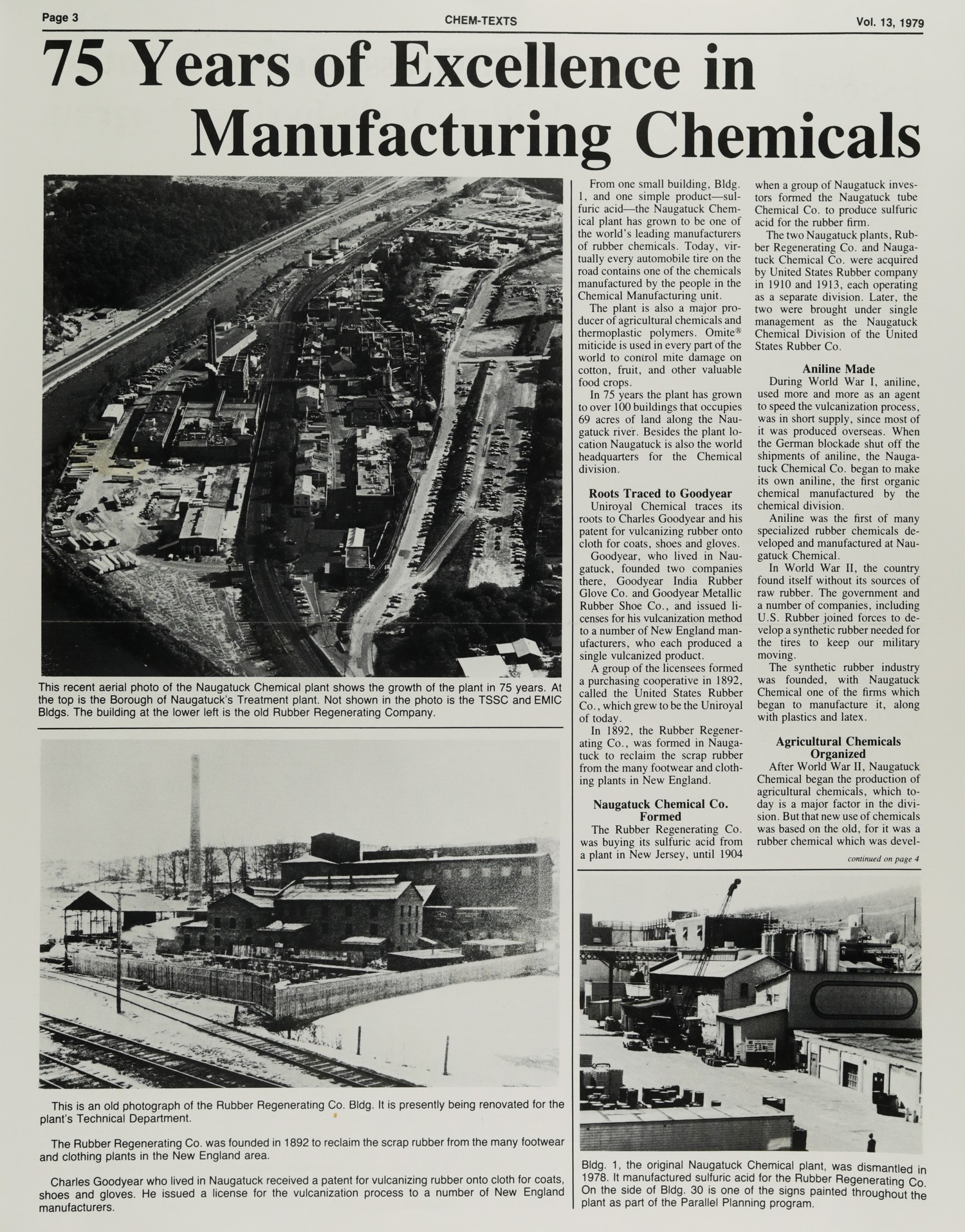

75 Years of Excellence in Manufacturing Chemicals

From one small building, Bldg. 1, and one simple product—sulfuric acid—the Naugatuck Chemical Co. has grown to become one of the world’s leading manufacturers of rubber chemicals. Today, virtually every automobile tire on the road contains one of the chemicals manufactured by the people in the Chemical Manufacturing unit.

The plant is also a major producer of agricultural chemicals and other industrial chemicals. Oxine, a herbicide used in every part of the world to control mite damage on cotton, fruit, and other valuable food crops.

In 75 years the plant has grown to cover 100 buildings that occupy 69 acres of land along the Naugatuck river. Besides the plant itself, the 69 acres also houses the world headquarters for the Chemical division.

Roots Traced to Goodyear

Uniroyal Chemical traces its roots to Charles Goodyear and his patent for vulcanizing rubber onto cloth for coats, shoes and gloves. He issued a license in Naugatuck, founded two companies there, Goodyear India Rubber Glove Co. and Goodyear Metallic Rubber Shoe Co., and issued licenses for his vulcanization method to a number of New England manufacturers, who each produced a single vulcanized product.

In 1892, the Rubber Regenerating Co., was formed in Naugatuck to reclaim the scrap rubber from the many footwear and clothing plants in the New England area.

Naugatuck Chemical Co. Formed

The Rubber Regenerating Co. was buying its sulfuric acid from a plant in New Jersey, until 1904 when a group of Naugatuck investors formed the Naugatuck Chemical Co. to produce sulfuric acid for the rubber firm.

The two Naugatuck plants, Rubber Regenerating Co. and Naugatuck Chemical Co. were acquired by United States Rubber company in 1910 and 1913, each operating as a separate division. Later, the two were brought under single management as the Naugatuck Chemical Division of the United States Rubber Co.

Aniline Made

During World War I, aniline, used more and more as an agent to speed the vulcanization process, was in short supply, since most of it was produced overseas. When the Naugatuck Chemical Co. began to make its own aniline, the first organic chemical manufactured by the Chemical division.

Aniline was the first of many specialized rubber chemicals developed and manufactured at Naugatuck.

In World War II, the country found itself without its sources of raw rubber. The Government and a number of companies, including U.S. Rubber joined forces to develop a synthetic rubber needed for the tires to keep our military moving.

Agricultural Chemicals Originated

After World War II, Naugatuck Chemical began the production of agricultural chemicals, which today is a major factor in the division. But that new use of chemicals was based on the old, for it was a rubber chemical which was developed.

This recent aerial photo of the Naugatuck Chemical plant shows the growth of the plant in 75 years. At the top is the Borough of Naugatuck’s Treatment plant. Not shown in the photo is the TSSC and EMIC Bldg. The building at the lower left is the old Rubber Regenerating Company.

This is an old photograph of the Rubber Regenerating Co. Bldg. It is presently being renovated for the plant’s Technical Department.

The Rubber Regenerating Co. was founded in 1892 to reclaim the scrap rubber from the many footwear and clothing plants in the New England area.

Charles Goodyear who lived in Naugatuck received a patent for vulcanizing rubber onto cloth for coats, shoes and gloves. He issued a license for the vulcanization process to a number of New England manufacturers, who each produced a single vulcanized product.

Bldg. 1, the original Naugatuck Chemical plant, was dismantled in 1978. It manufactured sulfuric acid for the Rubber Regenerating Co. On the side of Bldg. 30 is one of the signs painted throughout the plant as part of the Parallel Planning program.

—

## Page 282

Vol. 13, 1979

CHEM-TEXTS

Page 3

46 Employees Honored for Service

Forty six people were recently honored for their twenty five years or more service with the Uniroyal Chemical division. Seventeen who attained twenty five years of service were inducted into the Uniroyal Chemical Twenty Five Years Service Club, eight were made members of the Thirty Year Service Club, and seven were named to the Forty Year group.

The forty year members were presented with Grandfather Atmos Perpetual Motion clocks which are powered by the earth’s rotational movement. The clocks have a value of over $425.

Uniroyal Chemical Company’s 46 employees honored in the Chemical division represent close to 70% of the present personnel.

40 Years Service

James S. Carroll, Edna C. Cryderman, Harold R. Dibble, John J. Dunn, Julius V. Grabowski, Donald R. Nelson, Martin F. O’Brien, Joseph D. Rourk–(U.S. Steel) and Adele A. Schwenk.

35 Years Service

Vivian G. Abel, William E. Delfsen, Deolinda V. Fernandes, Chester E. Janicki, Edmund J. Levandauskas, George LaRosa, Samuel Mastoropoulos, Hilda L. Munn, Dr. Valdo C. McClarin, James J. Nolan, Paul E. Reed and Frank S. Seninka.

30 Years Service

Dr. Roger W. Amidon, Theodore Cesarczyk, Edward J. Chrostowski, Joseph L. Frlke, William H. Lenkhard Jr., Gordon H. Madge, William H. Schneickle and Otto E. Wenger.

25 Years Service

Miquel Aroyo, Louis M. DeLaRosa, Edward A. Gundlach, Marcel H. Hebert, Giuseppe Iannuzzi, Victor J. Kennedy, Sophie Kuzminskas, Helen S. Lavery, William J. Milevich, Frank M. Morgan, Arnold E. Neri, Walter F. Nystrom, Norman C. Ovens, Irwin A. Prager, Matthew T. Ryan, Theodore J. Shary and James B. Whitten.

New 25 Year Club members, Arnold Neri, left, and Guiseppe Iannuzzi, right, are welcomed into the Twenty-Five Year Club by Eric Johnson, center.

Home Health Care

Under Medicare

One of the least known benefits covered by Medicare, but one potentially available to many people, is home health care.

Home health care can be covered under either Medicare hospital insurance or Medicare medical insurance, depending on the circumstances of a particular case.

Home health care is for people who do not need full-time skilled care as inpatients of a medical facility, but rather who do have an illness or injury that prevents them from leaving home to receive the health care they need.

For further information on Home Health Care call the Social Security office in Waterbury, 756-475.

Theodore Cesarczyk is honored for his advancement into the 30 year group.

Stride Rite Corp. to

Purchase Footwear

Uniroyal, Inc. and The Stride Rite

Corporation have agreed in principle

to the sale of a substantial portion

of the assets of Uniroyal’s domestic

footwear business including certain

brand names, accounts receivable,

manufacturing facilities and goodwill

which will be newly formed by Stride Rite.

The purchase price and other terms

of the agreement have not been disclosed but it is anticipated that a definitive agreement will be executed

in the near future and the transaction

will be consummated shortly

thereafter.

Uniroyal will continue to produce

shoes for the purchaser in Dublin

and Thomson, Ga. plants.

Uniroyal will retain its U.S. industrial waterproof footwear and

clothing business at its Ball Maine

Ball line of hunting and fishing

clothing and waterproof footwear.

The Company also will continue to

operate its footwear businesses in Europe, Latin America and Asia.

Stride Rite currently markets footwear nationally and, through its

newly formed organization, plans

vigorous promotion of the footwear

brands to increase their market share.

Tire Plants Bldg. 28 Plan

Sold Saves $4000

in Steam

Uniroyal, Inc. and the Continental

Gummi Werke AG, the largest tire

company in Germany, have reached

agreement in which Continental

will acquire Uniroyal’s tire businesses in Europe. Included in the

transaction are Uniroyal’s tire plants

in Germany, France, Belgium and

the United Kingdom and a textile

plant in Luxembourg. The sale is

subject to the approvals of the Boards

of Directors of both companies.

In March, Bldg. 28 personnel

made a major change in plant operating policy that resulted in significant energy and cost savings.

The change in the plant has been to turn steam

onto vessels and tracer lines and to

leave the steam on. The reason was

simple: with literally hundreds of

steam lines in each building, it was

impossible to determine what steam

could be shut off in any given situation.

Continental, which has been a licensee of Uniroyal tire technology

for many years, will under a trademark license from Uniroyal and

Continental continue to produce,

manufacture and sell Uniroyal brand

tires in Europe and will aggressively

market them through Uniroyal’s

present distribution system, providing the same high level of quality

and service to Uniroyal’s customers.

In Bldg. 28, the decision was made

to change this. All the steam lines

and traps were tagged and the operating procedures are being written

that will instruct the operators just

what steam lines are needed for each

product. If steam is not needed, it

is shut off. This change requires participation by everyone involved.

The sale will provide funds for

Uniroyal’s redeployment of assets

program which increases reinvestment

in better growth and profit potential

areas.

The savings incurred in Bldg. 28

for the month of March show how

successful this policy can be. In

March of 1976 over 5,000,000 lbs.

of steam were used compared to only

1,500,000 lbs. in March 1979. This

dramatic drop in steam consumption

resulted in savings of $4,000 for

that month.

“A committee is a group that

keeps minutes and loses hours.”

– Milton Berle

Contributing to this effort were:

John Gilbert, Process Engineer; Frank

Commodaro, Foreman; Dick

Valentine; Department Manager,

John Pearson, Pipex; and Bldg. Operators: Dominic Perutti, Angelo

Taylor, Walt Scott, Henry Hook,

Frank Miller, Lee Repass, and Sal

Commodaro.

One Step at a Time

A journey of a thousand miles

begins with one step. If you face a

task today that is so long or so hard

that it seems overwhelming, remember that it

still begins with one step. Take that

one step, and the next, and then the

next. Don’t look too far ahead if it

is a poor view. Look at it now, and

meet only day as it comes; without

borrowing trouble from tomorrow.

Remember, the journey of a thousand

miles will be completed, one step at a time,

you keep taking one step at a time,

you can get through even a journey

of a thousand miles.

UNIROYAL, INC. COMMON STOCK PRICES

May–1979

—

## Page 285

Here is the text extracted from the document image, preserving the layout and structure as much as possible:

Page 2

CHEM-TEXTS

1978 was a Good Year…

You and I know our Company is starting to generate

an upward momentum as illustrated by the outstanding

performance of the Naugatuck Plant and the Chemical

Company in 1978. The Chemical Company profits exceeded all expectations last year and our Plant’s 1978

operating profit increased 58%.

This outstanding achievement is the result of your efforts

whether you are in Manufacturing, Research and Development, Accounting, D&S, the Service Departments, or

elsewhere.

Our plant’s goal is to have a 30% plant operating profit

that would result in a 9% return on sales. This year our

objective is to increase the return on sales from 3 to 4.5%.

How do we expect to achieve our profitability objective?

The answer to this question is reflected in the achievements

of last year.

In the Maintenance Department an outstanding job was

performed in reducing equipment downtime from 8.9 to

6.2%. Our year-end goal is 6% and January was an excellent

start with downtime averaging 4.5%.

Manufacturing productivity records in the production of Rubber Chemicals, Agricultural Chemicals, and

Thermoplastics. Omite, LVBI, Tenox, and TPR productivities increased between 20 and 30% while PANA and

Naugatuck 445 improved by 66%. Also a reduction in

Keylar changeovers was achieved through better coordination and communications. In addition, Corden, Harris,

P. Colden RA, and Polyard I. were successfully produced

in the Plant. All these achievements resulted in increasing

our Plant’s profitability by 58%.

Our Industrial Relations Department was reorganized

and is more effective in serving our needs. Safety Goals

were far exceeded with 1.2 incidence rate and Workmen’s

Compensation costs were reduced by $165,000. A new

performance appraisal system was initiated and a training

session held to help managers conduct performance ap-

praisals with their people.

A Controllers Department was established to perform

financial reporting, budgeting, forecasting, and economic

analysis; to conduct approvals of Appropriation Requests;

and to identify opportunities for cost improvement.

The Technical Department now includes all engineering

functions: process, project, environmental, and industrial

engineering. 2.3 million dollars of profit improvement was

realized through developing a team effort with the plant,

R & D, and marketing. This year a similar amount is expected through Project Enterprise, the name of our 1979

Profit Improvement Program. Over $300,000 was saved

through the work of the Plant’s Energy Committee. Other

savings were realized by the Environmental Department

in productivity records in Rubber Chemicals and Omite

as well as the successful production of Comtic, Octamine

P. Colden RA, and Polyard I.

In the Material Flow Department transportation credits

exceeded budget by $13,000. An additional $532,000 was

saved through improved transportation of our finished

goods. Shipping and receiving increased productivity by

7% and improved the service on export shipments. The

Purchasing Department and Control Center reduced our

inventory levels thereby increasing our return on assets.

In cost saving measures, our energy conservation programs

exceeded our expectations by $400,000 dollars.

A major objective is to improve the utilization of our

plant by introducing new products in our existing facilities

or attracting new manufacturing facilities because our

resources are underutilized. For example, we are using

only 50% of our steam generation and waste water treatment capacities while Rubber Chemicals is budgeted to

operate only between 60-65% of capacity this year. If

our plant’s operating profit would increase to approximately 27%. On some recent data it appears that a 10%

selling price increase would have the same impact as a

30% cost reduction.

1978 was a year of change and accomplishment.

We have the reputation of managing our business. Naugatuck seeks change. We are determined to overcome

our geographical raw material disadvantage through

PROFESSIONAL EXCELLENCE in every assignment

and job that is performed.

In 1979 Naugatuck seeks a Better Place To Be and

soon the Best Place To Be.

Eric Johnson

Factory Manager

Vol. 13, 1979

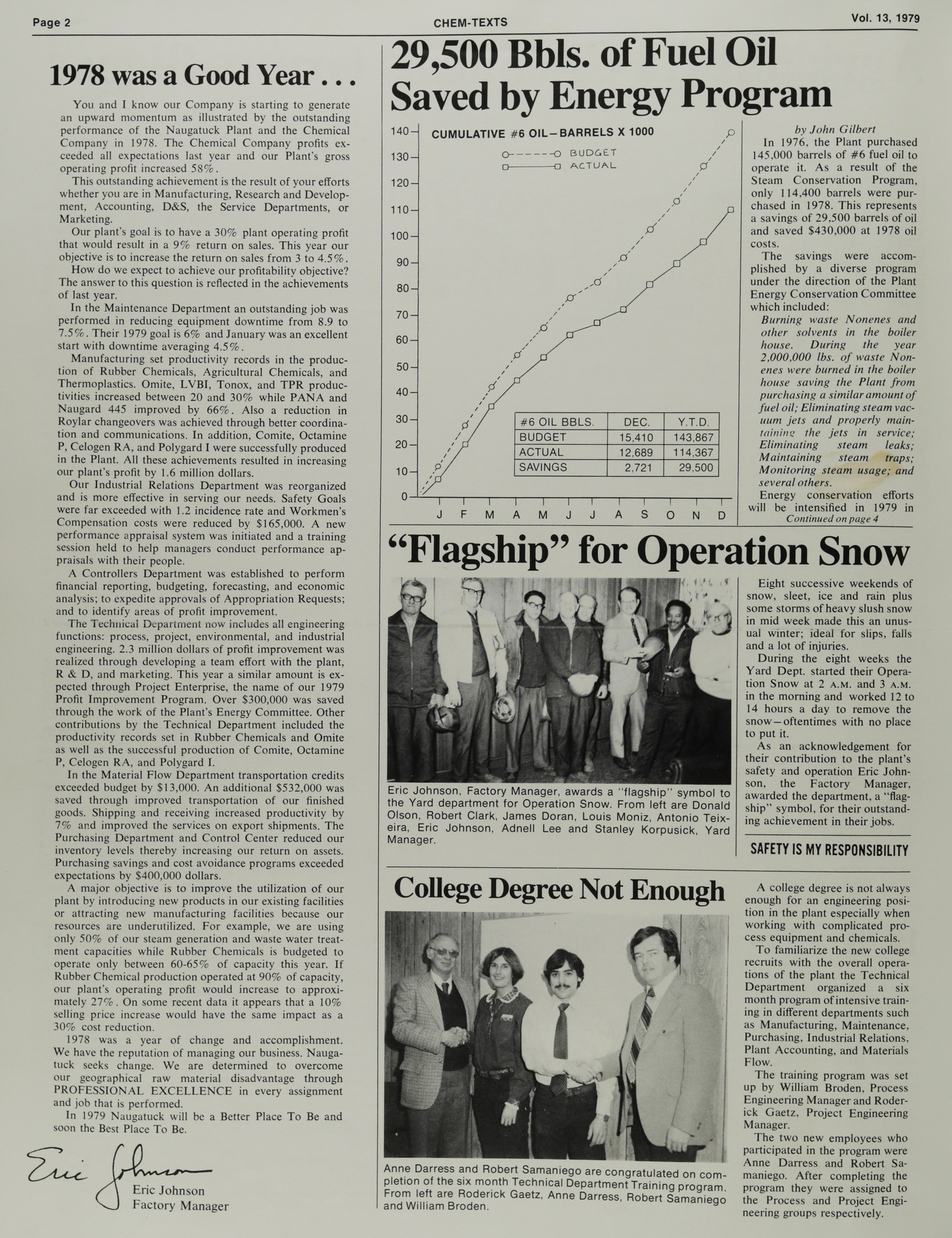

29,500 Bbls. of Fuel Oil

Saved by Energy Program

CUMULATIVE # OIL-BARRELS X 1000

BUDGET

ACTUAL

SAVINGS

6 OIL BBLS

BUDGET

ACTUAL

SAVINGS

DEC

15,110

12,689

2,721

Y.T.D.

143,867

114,367

29,500

“Flagship” for Operation Snow

Eric Johnson, Factory Manager, awards a “flagship” symbol to

the Yard department for Operation Snow. From left are Donald

Olson, Robert Clark, James Doran, Louis Moniz, Antonio Teixeira, Eric Johnson, Ardell Lee and Stanley Korpusicek, Yard

Manager.

College Degree Not Enough

Anne Darress and Robert Samaniego are congratulated on completion of the six month Technical Department Training program.

From left are Roderick Gaetz, Anne Darress, Robert Samaniego

and William Broden.

Eight successive weekends of

snow, sleet, ice and rain plus

some storms of heavy slush snow

in mid week made this an unusual winter; ideal for slips, falls

and a lot of injuries.

During the eight weeks the

Yard Dept. started their Operation Snow at 2 A.M. and 3 A.M.

and continuously worked up to

14 hours a day to remove the

snow—sometimes with no place

to put it.

As an acknowledgement for

their contribution to the plant’s

safety and operation, Eric Johnson, the Factory Manager,

awarded the department a “flagship” symbol for their outstanding achievement in their jobs.

SAFETY IS MY RESPONSIBILITY

A college degree is not always

enough for an engineering position in the plant especially when

working with complicated process equipment and chemicals.

To familiarize the new college

recruits with the overall operations of the Technical

Department, a six

month program of intensive train-

ing in different departments such

as Manufacturing, Maintenance,

Purchasing, Industrial Relations,

Plant Accounting, and Materials

Flow.

The training program was set

up the William Broden, Process

Engineering Manager and Roderick Gaetz, Project Engineering

Manager.

The two new employees who

participated in the program were

Anne Darress and Robert Samaniego. After completing the

program they were assigned to

the Process Engineering groups respectively.

—