## Page 001

Chem World

Published by Uniroyal Chemical Co. for its Employees and Retirees January 1991

Contents

Cotton Aid For U.S.S.R. . . . . . . . 2

A Talk With Walter J. Cook . . . 3

Recycling Is Good Business . . . . 4

Annual Quality Award Winners 5

Supplier Awards For Quality . . . 6

ChemWorld Briefs . . . . . . . . . . . 8

Uniroyal Chemical Expands Internationally

To help strengthen the company’s position in the international chemical arenas, Uniroyal Chemical recently established new offices in Langley, England and Tokyo, Japan. These offices enhance Uniroyal Chemical’s global capabilities by enabling the company to provide premier chemical products and services to customers in any area of the world.

Consolidation of European Office

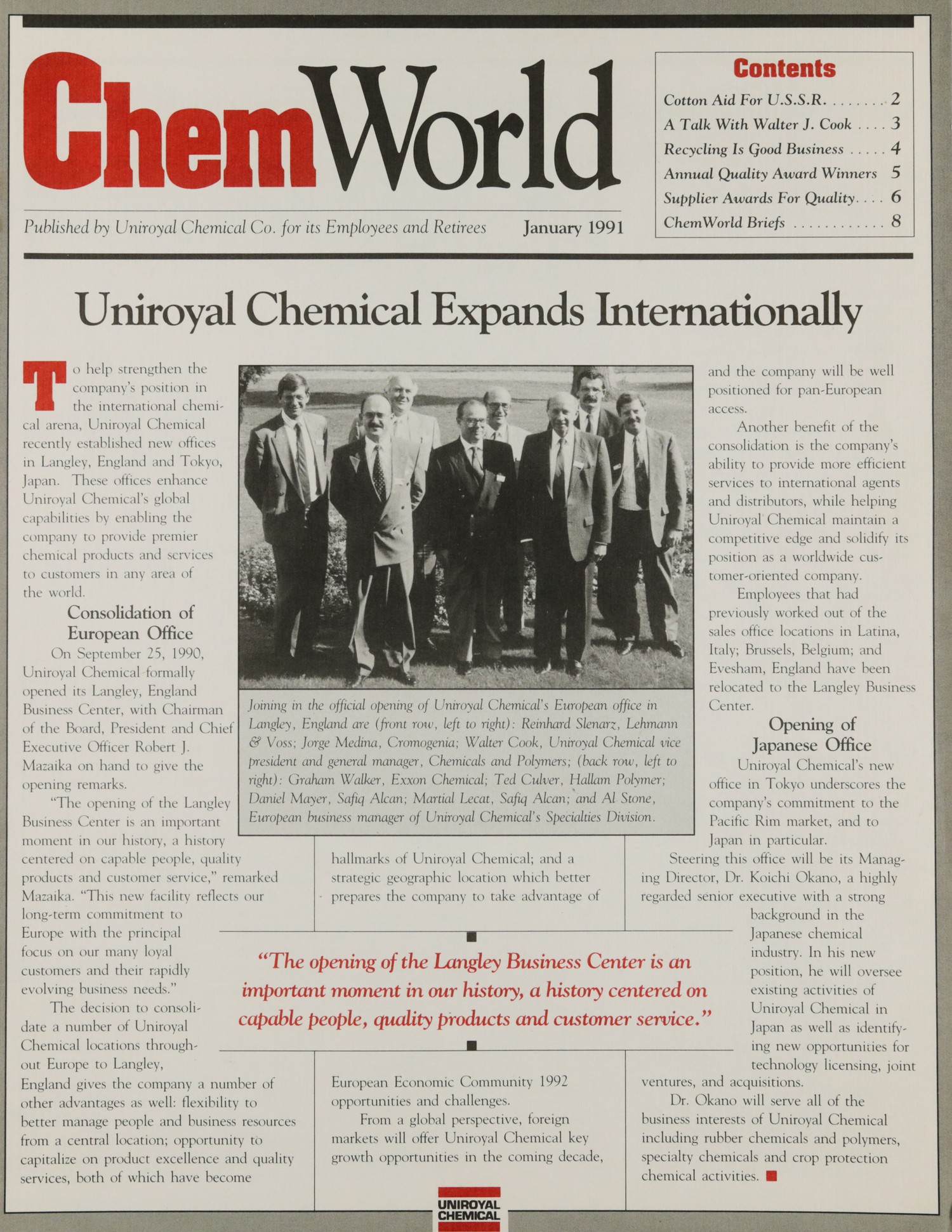

On September 25, 1990, Uniroyal Chemical formally opened its Langley, England Business Center, with Chairman of the Board, President and Chief Executive Officer Robert J. Masaika on hand to give the opening remarks.

“The opening of the Langley Business Center is an important moment in our history, a history centered on capable people, quality products and customer service,” remarked Masaika. “This new facility reflects our long-term commitment to Europe with the principal focus on our many loyal customers and their rapidly evolving business needs.”

The decision to consolidate a number of Uniroyal Chemical locations throughout Europe to Langley, England gives the company a number of other advantages as well: flexibility to better manage people and business resources from a central location; opportunity to capitalize on product excellence and quality services, both of which have become hallmarks of Uniroyal Chemical; and a strategic geographic location which better prepares the company to take advantage of European Economic Community 1992 opportunities and challenges.

From a global perspective, foreign markets will offer Uniroyal Chemical key growth opportunities in the coming decade; and the company will be well positioned for pan-European access.

Another benefit of the consolidation is the company’s ability to provide more efficient services to international agents and distributors, while helping Uniroyal Chemical maintain a competitive edge and solidify its position as a worldwide customer-oriented company.

Employees that had previously worked out of the sales office locations in Latina, Italy; Brussels, Belgium; and Evesham, England have been relocated to the Langley Business Center.

Opening of Japanese Office

Uniroyal Chemical’s new office in Tokyo underscores the company’s commitment to the Pacific Rim market, and to Japan in particular. Steering this office will be its Managing Director, Dr. Koichi Okano, a highly regarded senior executive with a strong background in the Japanese chemical industry. In his new position, he will oversee existing activities of Uniroyal Chemical in Japan as well as identifying new opportunities for technology licensing, joint ventures, and acquisitions.

Dr. Okano will serve all the business interests of Uniroyal Chemical including rubber chemicals and polymers, specialty chemicals and crop protection chemical activities.

Joining in the official opening of Uniroyal Chemical’s European office in Langley, England are (from left to right): Voss: Jorge Medina, Cromogenic; Walter Cook, Uniroyal Chemical vice president and general manager, Chemicals and Polymers; (back row, left to right): Grolman, Salley; Effron Charney, Technical Director, William Polaner, Daniel Mayer, Saliq Alem; Martial Lecat, Saliq Alem; and Al Stone, European Business manager of Uniroyal Chemical’s Specialties Division.

“The opening of the Langley Business Center is an important moment in our history, a history centered on capable people, quality products and customer service,” remarked Masaika. “This new facility reflects our long-term commitment to Europe with the principal focus on our many loyal customers and their rapidly evolving business needs.”

—

## Page 002

Uniroyal Chemical Aids U.S.S.R. Cotton Industry

In the spirit of glasnost, Uniroyal Chemical recently launched an integrated cotton improvement program in the U.S.S.R., symbolizing its commitment to developing business in Soviet Central Asia. The program represents a giant step towards establishing Uniroyal Chemical as a leader in worldwide harvest and technology.

SIBIR, Inc., USA, a business development/consulting firm which has a joint venture in Soviet Central Asia to advance the cotton industry, approached Uniroyal Chemical to help the Soviet cotton industry develop harvest aids, and ultimately to become more competitive.

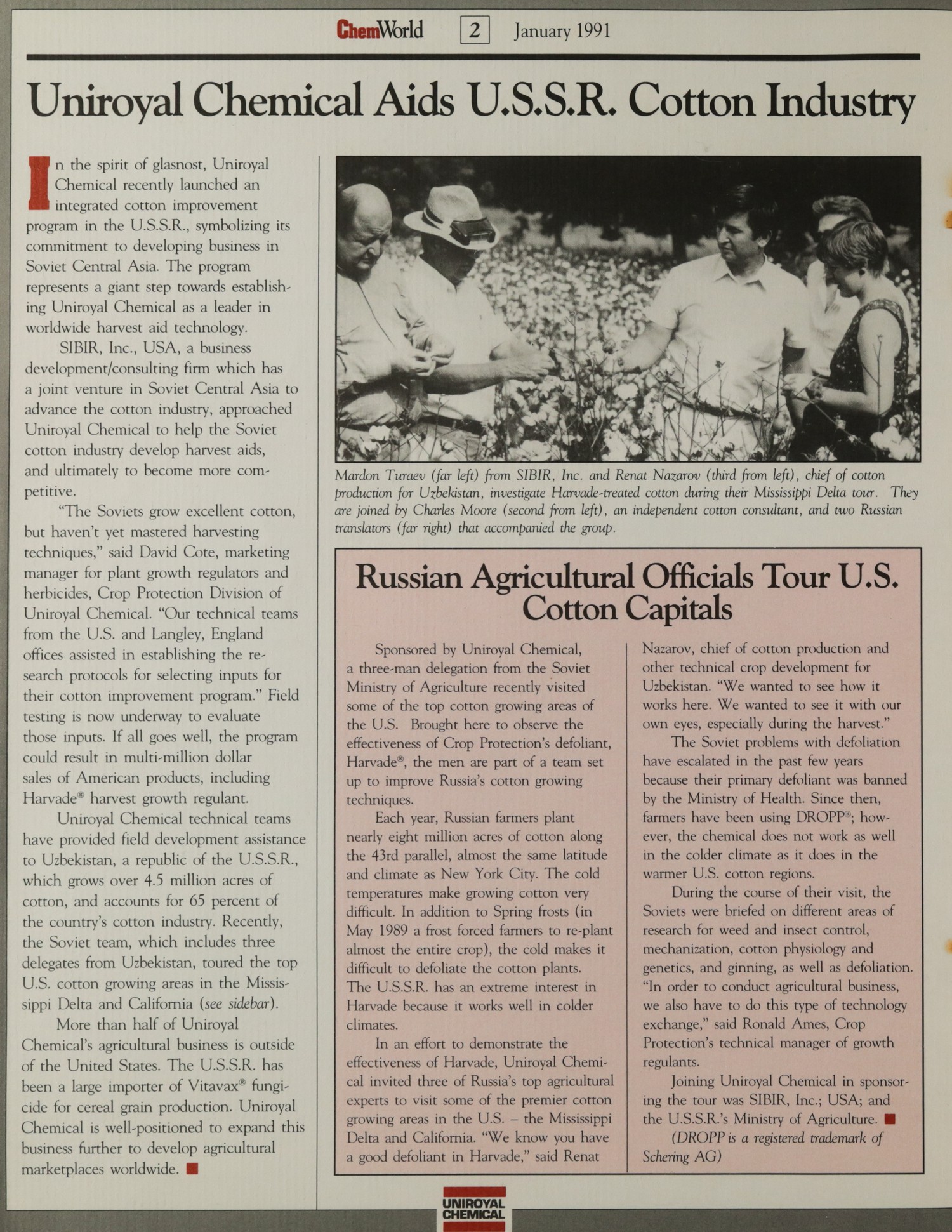

“The Soviets grow excellent cotton, but haven’t yet mastered harvesting techniques,” said David Core, marketing manager for plant growth regulators and herbicides, Crop Protection Division of Uniroyal Chemical. “Our technical teams from the U.S. and Langley, England offices assisted in establishing the research protocols for selecting inputs for their cotton improvement program.” Field testing is now underway to evaluate those inputs. If all goes well, the program could result in multi-million dollar sales of American products, including Harvade® harvest growth regulant.

Uniroyal Chemical technical teams have provided field development assistance to Uzbekistan, a republic of the U.S.S.R., which grows over 4.5 million acres of cotton, and accounts for 65 percent of the country’s cotton industry. Recently, the Soviet team, which included three delegates from Uzbekistan, toured the top U.S. cotton growing areas in the Mississippi Delta and California (see sidebar). More than half of Uniroyal Chemical’s agricultural business is outside of the United States. The U.S.S.R. has been a large importer of Vitavax® fungicide for cereal grain production. Uniroyal Chemical is well-positioned to expand this business further to develop agricultural marketplaces worldwide.

Russian Agricultural Officials Tour U.S. Cotton Capitals

Sponsored by Uniroyal Chemical, a three-man delegation from the Soviet Ministry of Agriculture recently visited some of the top cotton growing areas of the U.S. Brought here to observe the effectiveness of Crop Protection’s defoliant, Harvade®, the men are part of a team set up to improve Russia’s cotton growing techniques.

Each year, Russian farmers plant nearly eight million acres of cotton along the 43rd parallel, almost the same latitude and climate as New York City. The cold temperatures make growing cotton very difficult. In addition to Spring frosts (in May 1989 a frost forced farmers to re-plant almost the entire crop), the cold makes it difficult to defoliate the cotton plants.

The U.S.S.R. has an extreme interest in Harvade® because it works well in colder climates. In an effort to demonstrate the effectiveness of Harvade®, Uniroyal Chemical invited three of Russia’s top agricultural experts to visit some of the premier cotton growing areas in the U.S. – the Mississippi Delta and California. “We know you have a good defoliant in Harvade®,” said Renat Nazarov, chief of cotton production and other technical crop development for Uzbekistan. “We wanted to see how it works here. We wanted to see it with our own eyes, especially during the harvest.”

The Soviet problems with defoliation have escalated in the past few years because their primary defoliant was banned by the Ministry of Health. Since then, farmers have been using DROPP®; however, the chemical does not work as well in the cooler climate as it does in the warmer U.S. cotton regions.

During the course of their visit, the Soviets were briefed on different areas of research for weed and insect control, mechanization, cotton physiology and genetics, and ginning, as well as defoliation. “In order to conduct agricultural business, we also have to do this type of technology exchange,” said Ronald Ames, Crop Protection’s technical manager of growth regulants.

Joining Uniroyal Chemical in sponsoring the tour was SIBIR, Inc.; USA; and the U.S.S.R.’s Ministry of Agriculture. (DROPP® is a registered trademark of Schering AG)

—

## Page 003

New Product Technologies And Global Expansion Drive Chemicals And Polymers Division

Walter J. Cook, vice president and general manager of the Chemicals and Polymers (C&P) Division, recently talked about the division’s strengths and future worldwide expansion plans. The following is a summary of this interview:

Q. Despite the slowdown in the U.S. economy and the volatile global economy throughout 1990, the C&P Division turned in a commendable performance. What factors are responsible for this success during a time when many other industrial companies are struggling just to stay in business?

A. The C&P Division indeed turned in a commendable performance. However, I was disappointed that we did not make our budgeted sales and profit in 1990. During the last quarter of 1990, we were severely impacted by sales in the U.S.S.R. We have demonstrated to our many worldwide customers, however, that we are a very competitive, dependable supplier working very hard to provide the best quality products and service backed by a strong technical department, both in research and development and technical service.

Q. The third Rovalene® EPDM production unit, known as Poly III, is slated to come on stream in March/April of 1991, making Uniroyal Chemical the largest producer of EPDM in North America. What strategy determined the need for this additional capacity and how will this capital investment affect the company’s MBO financial status?

A. We have become a worldwide leader in the EPDM business, and this expansion is a strong commitment to this fundamental position. In addition to our solid base in several key markets in North America, we have strategic market penetration in Latin America and Europe and support our licensees in Japan, Korea and India. We are very confident in meeting and exceeding our financial projections despite the heavy capital investment we are making in Poly III. This expansion will give us a satisfactory return on the capital deployed and help strengthen our MBO projections.

Q. What new markets or product applications do you see for the Paracril® nitrile rubber business?

A. We have been very pleased with the progress of our Paracril business over the last year and a half. Despite a weakening economy and a reduced market for nitrile rubber, we have continued to gain market position. Our nitrile technologists have developed a non-mold foaling nitrile rubber that has been adopted by a major customer, and we have continuing business every month from this product. We are in the final approval stages of a nitrile for craft pump hoses from another customer, and we are developing several new products for a third customer’s European manufacturing sites.

Q. Are there currently any new product technologies under development, or plans for a new product introduction in the near future?

A. Our technology thrust is very broad and must satisfy a multitude of areas. For example, we look at our comprehensive R&D programs to address business strategies that put us on the leading edge of our core technologies, address customer needs for new products, focus process development to minimize effluents and emissions, extend our technology into new markets, and impact commercial activities globally. As for products, we are very optimistic about the commercial introduction of Durazone 37, our non-nitrosamine regenerating accelerators, new wire adhesion promoters, several new Royalene types for specific markets in Europe, and expanded sales of Royaltherm® silicone-modified EPDM, Royalfui® impact modifiers and Tritene® liquid EPDM. Although the latter three products are managed by our Corporate Business Development group, we move these products through our division’s customer base.

Q. What is the status of Durazone™ 37, the nonstainting antiozonant introduced in 1989?

A. Durazone 37 is a proprietary, nonstainting dynamic nitrile chemical offering ozone resistance and improved flex life for rubber-based products. We have commercial sales in the rubber host market and we are in our second, and hopefully final fleet testing program with an overseas tire manufacturer. We are very optimistic that this testing will be satisfactory and will lead to commercial adoption of this product in the manufacture of car and truck tires by July 1991.

—

## Page 004

Recycling Plastics Is Good Business

Problems and opportunities are often opposite sides of the same coin. A current societal problem which represents a significant opportunity for Uniroyal Chemical is the crisis surrounding the scarcity of landfill space in many parts of the country. As a supplier to the plastics industry, Uniroyal Chemical is committed to producing and selling products which will enhance the “environmental friendliness” of customers’ products.

By 1992, 25 percent of the nation’s solid waste should be recycled, according to the Environmental Protection Agency. Unfortunately for the plastics industry, there is a commonly-held misconception that plastics are not recyclable. Another purported shortcoming of plastics is that they are a waste of non-renewable petroleum resources.

Uniroyal Chemical and various industry associations, such as the Society of the Plastics Industry and the Society of Plastics Engineers, are now launching an all-out effort to educate the public to the true environmental impact of plastics manufacture and use. Statistics are readily available which demonstrate that plastics are no more hazardous to produce or use than any other material.

The principal thrust of educational efforts has been aimed at the central issue of plastics recyclability. The concept that plastics cannot be recycled has been unchallenged for so long that it has become “gospel” to large numbers of people.

While the technology to recycle most types of plastics is well-known, this new industry is not without its problems. Chief among these, and a fact which may account for the view that plastics cannot be recycled, is that plastics are most easily recycled when they are segregated by type prior to processing. Different types of plastics may be incompatible, so that when they are melted together, they do not form a cohesive blend and consequently lack strength. Often, however, plastics are not segregated.

Uniroyal Chemical is currently is developing a line of polymer modifiers to upgrade the properties of recycled resins. Royaltuf*, a modified ethylene propylene elastomer (rubber), is a family of polymer modifiers that is designed to increase toughness or to raise the impact properties of plastics, and to function as a compatibilizer enabling successful blending of otherwise incompatible resins. In many cases, the use of Royaltuf modifiers will allow a plastics producer to make engineering plastics out of recycled resins.

Many applications for recycled plastics are in the area of wood replacement. One characteristic of most plastics is that they are inherently heavier than wood. In order to give these products a more “wood-like” nature, many recyclers are using foaming agents to reduce weight. Given the fact that the recycled plastic feed stream will certainly not be as consistent as a virgin resin feed, the demands for flexibility placed on the foaming agent system will be great. As the only domestic manufacturer of chemical foaming agents (Celogen*, Kempore*, Nitropen*, Opex* and Expancel*), Uniroyal Chemical is devoting considerable attention to this issue as well.

Recycling is here to stay. Uniroyal Chemical is dedicated to supplying materials to the industry which will make the job easier and more profitable. And, as evidence that the company is truly committed, it has initiated its own recycling program within the company, segregating classes of materials and designating recycling coordinators for each department to ensure that waste is recycled.

Also, several technical employees of Uniroyal Chemical Company and other area companies are working with the Society of Plastics Engineers to organize a conference on plastics recycling in New England scheduled for June, 1991. The conference will seek to educate people from local governments, area industry, and universities on the facts about plastics recycling.

PLASTICS (SOLID WASTE) FACTS

– Producing paper bags requires more energy and oil (as well as trees) than producing plastic bags. It also produces more pollutants.

– Plastics were found to occupy only 18 percent by volume of waste generated in the United States in 1986, compared to paper, which generated 38 percent by volume.

– Garbage incineration is actually helped by plastics in the trash because plastics burn hotter, providing improved combustion which can lower emissions.

– The manufacture of all plastics uses only about two percent of the crude oil and natural gas consumed annually in the U.S.

– Plastics in the average car cut fuel consumption by nearly five percent and contribute to improved safety performance.

– Plastic packaging has helped reduce food spoilage in the industrialized world to around two percent. Developing countries have a spoilage rate of between 30 and 50 percent.

While thermoplastics may be melted and reshaped, the use of excessive thermal energy may lead to degradation of the plastic. It is important that the stabilizers used in a plastic to be recycled are up to the task of withstanding multiple heat histories. Uniroyal Chemical includes such evaluations in the testing of its existing line of thermal stabilizers (Naugard* antioxidants), as well as in the development of new versions. Additionally, stabilizers may have a tendency to migrate out of the plastics over time, so that stabilizers for plastics to be recycled must have a higher than normal degree of permanence.

—

## Page 005

Uniroyal Chemical Names Annual Quality Award Winners and Career Achievement Recipient

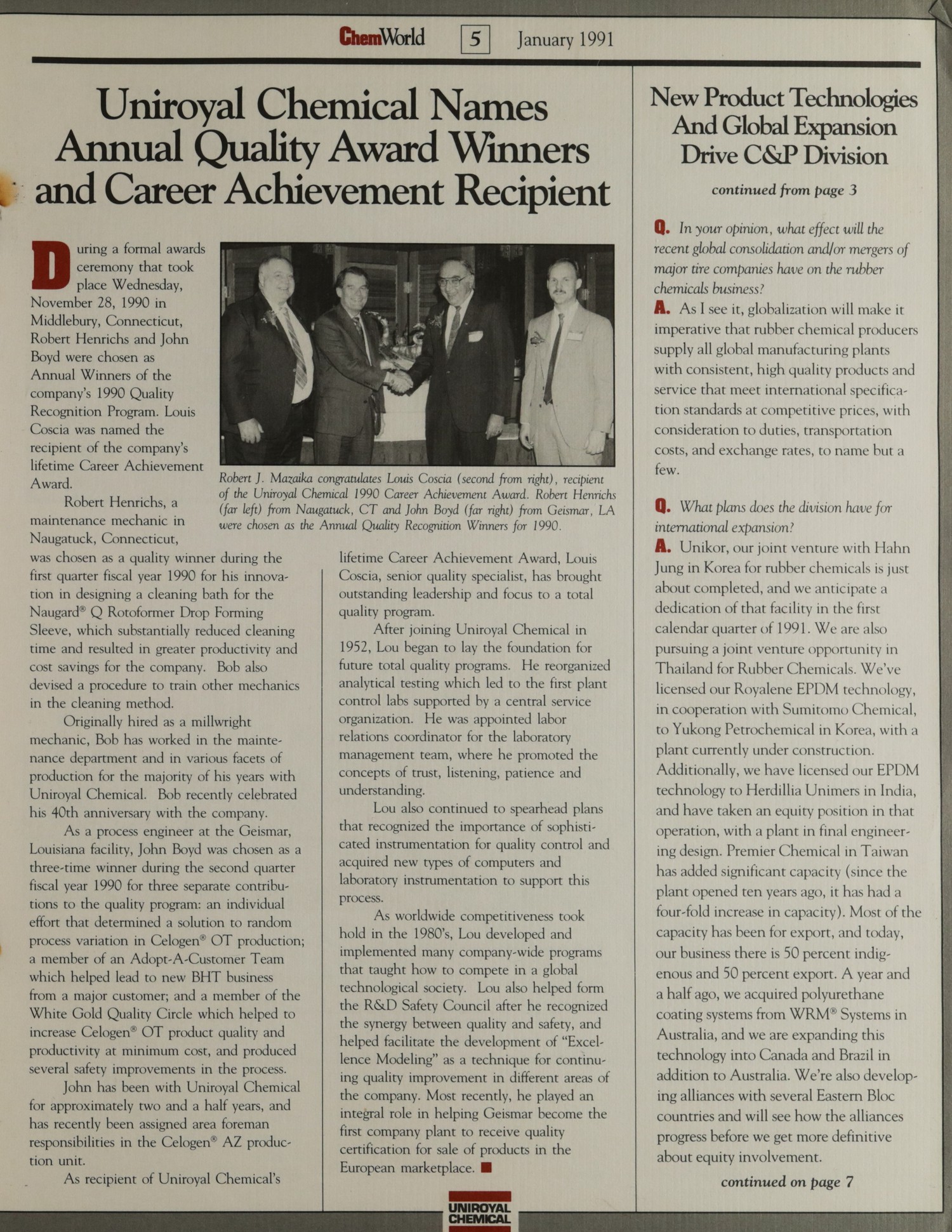

During a formal awards ceremony that took place Wednesday, November 28, 1990 in Middlebury, Connecticut, Robert Henrichs and John Boyd were chosen as Annual Winners of the company’s 1990 Quality Recognition Program. Louis Coscia was named the recipient of the company’s lifetime Career Achievement Award.

Robert Henrichs, a maintenance mechanic in Naugatuck, Connecticut, was chosen as a quality winner during the first quarter fiscal year 1990 for his innovation in designing a cleaning bath for the Naugatuck® QR Reformer Drip Fusing Sleeve, which substantially reduced cleaning time and resulted in greater productivity and cost savings for the company. Bob also devised a procedure to train other mechanics in the cleaning method.

Originally hired as a millwright mechanic, Bob has worked in the maintenance department and in various facets of production for the majority of his years with Uniroyal Chemical. Bob recently celebrated his 40th anniversary with the company.

As a process engineer at the Geismar, Louisiana facility, John Boyd was chosen as a three-time winner during the second quarter fiscal year 1990 for three separate contributions to the quality program: an individual effort that determined a solution to random process variation in Celgene® OT production, a member of an Adopt-A-Customer Team which helped lead to a major BHT business from a major customer, and a member of the White Gold Quality Circle which helped to increase Celgene® OT product quality and productivity at minimum cost, and produced several safety improvements in the process.

John has been with Uniroyal Chemical for approximately two and a half years, and has recently been assigned area foreman responsibilities in the Celgene® AZ production unit.

As recipient of Uniroyal Chemical’s lifetime Career Achievement Award, Louis Coscia, senior quality specialist, has brought outstanding leadership and focus to a total quality program.

After joining Uniroyal Chemical in 1952, Lou began to lay the foundation for future total quality programs. He reorganized analytical testing which led to the first plant control labs supported by a central service organization. He was appointed labor relations coordinator for the laboratory management team, where he promoted the concepts of trust, listening, patience and understanding.

Lou also continued to spearhead plans that recognized the importance of sophisticated instrumentation for quality control and acquired new types of computers and laboratory instrumentation to support this process.

As worldwide competitiveness took hold in the 1980’s, Lou developed and implemented many company-wide programs that taught how to compete in a global technological society. Lou also helped form the R&D Safety Council after he recognized the synergy between quality and safety, and helped facilitate the development of “Excellence Modeling” as a technique for continuing quality improvement in different areas of the company. Most recently, he played an integral role in helping Geismar become the first company plant to receive quality certification for sale of products in the European marketplace.

New Product Technologies And Global Expansion Drive C&P Division

Continued from page 3

Q. In your opinion, what effect will the recent global consolidation and/or mergers of major tire companies have on the rubber/chemicals business?

A. As I see it, globalization will make it imperative that rubber chemical producers supply all global manufacturing plants with consistent, high quality products and service that meet international specification standards at competitive prices, with consideration to duties, transportation costs, and exchange rates, to name but a few.

Q. What plans does the division have for international expansion?

A. Unikor, our joint venture with Hahn Jung in Korea for rubber chemicals is just about completed, and we anticipate a dedication of that facility in the first calendar quarter of 1991. We are also pursuing a joint venture opportunity in Thailand for Rubber Chemicals. We’ve licensed our Royalene EPDM technology, in cooperation with Sumitomo Chemical, to Yukong Petrochemical in Korea, with a plant currently under construction. Additionally, we have licensed our EPDM technology to Hercules Unieres in India, and have taken an equity position in that operation, with a plan for final engineering design. Premier Chemical in Taiwan has added significant capacity (since the plant opened ten years ago, it has had a four-fold increase in capacity). Most of the capacity has been for export, and today, over 50 percent of our business there is indigenous and 50 percent export. A year and a half ago, we acquired polyurethane coating systems from WRM* Systems in Australia, and we are expanding this technology into Canada and Brazil in addition to Australia. We’re also developing alliances with several Eastern Bloc countries and will see how the alliances progress before we get more definitive about equity involvement.

—

## Page 006

Uniroyal Chemical Receives Two Supplier Quality Awards For Its Royalene EPDM Business

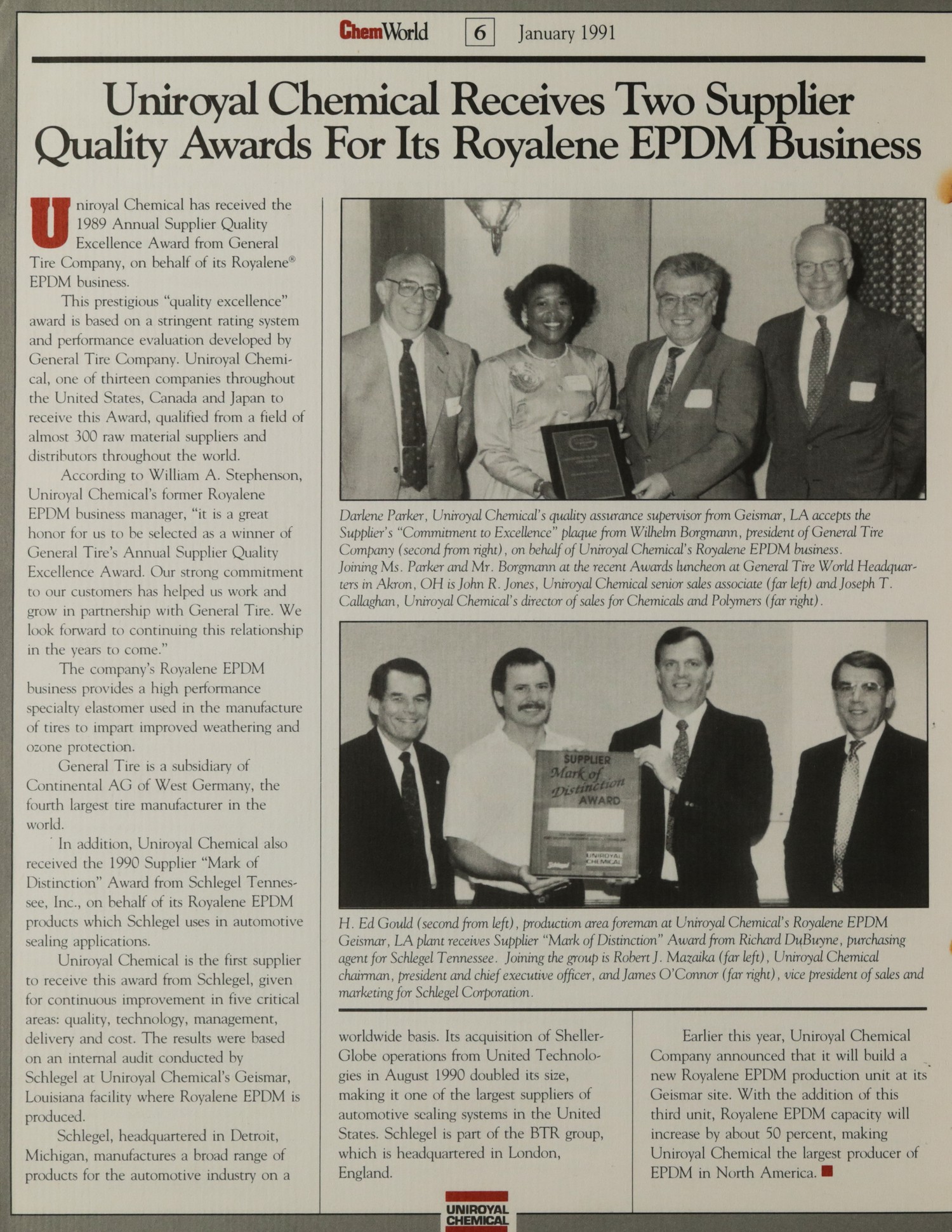

Uniroyal Chemical has received the 1989 Annual Supplier Quality Excellence Award from General Tire Company, on behalf of its Royalene EPDM business.

This prestigious “quality excellence” award is based on a stringent rating system and performance evaluation developed by General Tire Company. Uniroyal Chemical, one of thirteen companies throughout the United States, Canada and Japan to receive this Award, qualified from a field of almost 300 raw material suppliers and distributors throughout the world.

According to William A. Stephenson, Uniroyal Chemical’s former Royalene EPDM business manager, “it is a great honor for us to be selected as a winner of General Tire’s Annual Supplier Quality Excellence Award. Our strong commitment to our customers has helped us work and grow in partnership with General Tire. We look forward to continuing this relationship in the years to come.”

The company’s Royalene EPDM business provides a high performance specialty elastomer used in the manufacture of tires to impart improved weathering and ozone protection.

General Tire is a subsidiary of Continental AG of West Germany, the fourth largest tire manufacturer in the world.

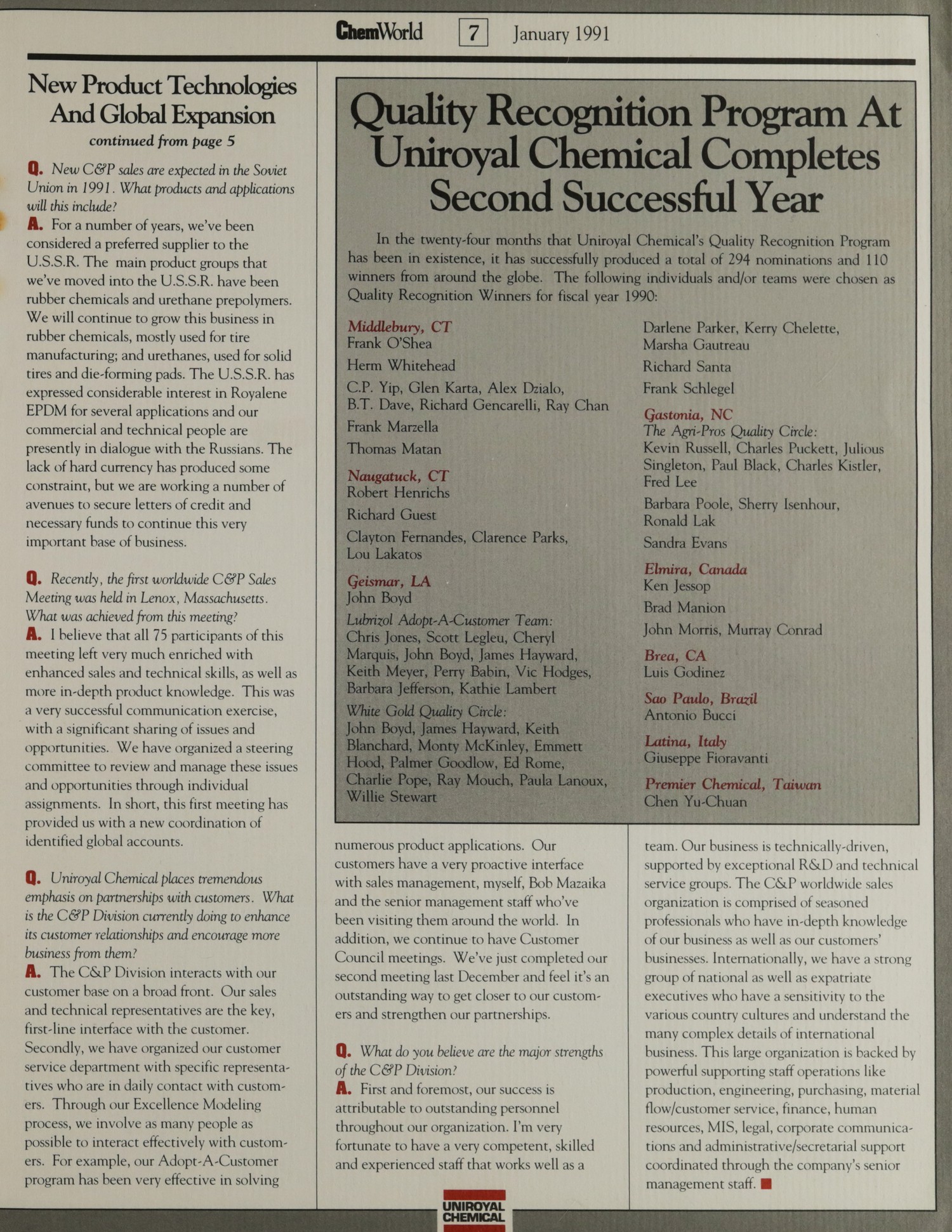

In addition, Uniroyal Chemical also received the 1990 Supplier “Mark of Distinction” Award from Schlegel Tennessee, Inc., on behalf of its Royalene EPDM products which Schlegel uses in automotive applications.

Uniroyal Chemical is the first supplier to receive this award from Schlegel, given for continuous improvement in five critical areas: quality, technology, management, delivery and cost. The results were based on an internal audit conducted by Schlegel at Uniroyal Chemical’s Geismar, Louisiana facility where Royalene EPDM is produced.

Schlegel, headquartered in Detroit, Michigan, manufactures a broad range of products for the automotive industry on a worldwide basis. Its acquisition of Sheller-Globe operations from United Technologies in August 1990 doubled its size, making it one of the largest suppliers of automotive sealing systems in the United States. Schlegel is part of the BTR group, which is headquartered in London, England.

Earlier this year, Uniroyal Chemical Company announced that it will build a new Royalene EPDM production unit at its Geismar site. With the addition of this third unit, Royalene EPDM capacity will increase by about 50 percent, making Uniroyal Chemical the largest producer of EPDM in North America.

—

## Page 007

ChemWorld 7 January 1991

New Product Technologies

And Global Expansion

continued from page 5

Q. New C&P sales are expected in the Soviet

Union in 1991. What products and applications

will this include?

A. For a number of years, we’ve been

considered a preferred supplier to the

U.S.S.R. The main product groups that

we’ve moved into the U.S.S.R. have been

rubber chemicals and urethane prepolymers.

We will continue to grow this business in

rubber chemicals, mostly used for tire

manufacturing and urethanes, used for solid

tires and die-forming pads. The U.S.S.R. has

expressed considerable interest in Royalene

EPDM for several applications and our

commercial and technical people are

presently in dialogue with the Russians. The

lack of hard currency has produced some

constraint, but we are working a number of

avenues to secure letters of credit and

necessary funds to continue this very

important base of business.

Q. Recently, the first worldwide C&P Sales

Meeting was held in Lenox, Massachusetts.

What was achieved from this meeting?

A. I believe that all 75 participants of this

meeting left very much enriched with

enhanced sales and technical skills, as well as

more in-depth product knowledge. This was

a very successful communication exercise,

with a significant sharing of issues and

opportunities. We have organized a steering

committee to review and manage these issues

and opportunities through individual

assignments. In short, this first meeting has

provided us with a new coordination of

identified global accounts.

Q. Uniroyal Chemical places tremendous

emphasis on partnerships with customers. What

is the C&P Division currently doing to enhance

its customer relationships and encourage more

business from them?

A. The C&P Division interacts with our

customer base on a broad front. Our sales

and technical representatives are the key,

first-line interface with the customer.

Secondly, we have organized our customer

service department with specific representatives who are in daily contact with customers. Through our Excellence Modeling

process, we involve as many people as

possible to interact effectively with customers. For example, our Adopt-A-Customer

program has been very effective in solving

Quality Recognition Program At

Uniroyal Chemical Completes

Second Successful Year

In the twenty-four months that Uniroyal Chemical’s Quality Recognition Program

has been in existence, it has successfully produced a total of 294 nominations and 110

winners from around the globe. The following individuals and/or teams were chosen as:

Quality Recognition Winners for fiscal year 1990:

Middlebury, CT

Frank O’Shea

Herm Whitehead

Geismar, LA

John Boyd

Naugatuck, CT

Robert Henriets

Richard Guest

Lubrizol Adopt-A-Customer Team:

Chris Jones, Scott Ledger, Cheryl

Marquis, John Boyd, James Hayward,

Keith Meyer, Perry Babin, Vic Hodges,

Barbara Jamieson, Kathie Lambert

Clayton Fernandes, Clarence Parks,

Lou Lalarios

White Gold Quality Circle:

John Boyd, James Hayward, Keith

Blanchard, Monty McKinley, Emmett

Hood, Palmer Goodlow, Ed Rome,

Charlie Pope, Ray Mouch, Paula Lanoux,

Willie Stewart

numerous product applications. Our

customers have a very proactive interface

with sales management, myself, Bob Mizulia

and the senior management staff who’ve

been visiting them around the world. In

addition, we continue to have Customer

Council meetings. We’ve just completed our

second meeting last December and feel it’s an

outstanding way to get closer to our customers and strengthen our partnerships.

Q. What do you believe are the major strengths

of the C&P Division?

A. First and foremost, our success is

attributable to outstanding personnel

throughout our organization. I’m very

fortunate to have a very competent, skilled

and experienced staff that works well as a

team. Our business is technically-driven,

supported by exceptional R&D and technical

service groups. The C&P worldwide sales

organization is comprised of seasoned

professionals who have in-depth knowledge

of our business as well as our customers’

businesses. Internationally, we have a strong

group of national as well as expatriate

executives who have a sensitivity to the

various country cultures and understand the

many complex details of international

business. This large organization is backed by

powerful supporting staff operations like

production, engineering, purchasing, material

flow/customer service, finance, human

resources, MIS, legal, corporate communications and administrative/secretarial support

coordinated through the company’s senior

management staff.

Darlene Parker, Kerry Chelette,

Marsha Gautreau

Richard Santa

Frank Schilegi

Gastonia, NC

The Agri-Pros Quality Circle:

Kevin Russell, Charles Puckett, Julius

Singleton, Paul Black, Charles Kisiler,

Fred Lee

Barbara Poole, Sherry Isenhour,

Ronald Lisk

Sandra Evans

Elmira, Canada

Ken Jessop

Brad Manning

John Morris, Murray Conrad

Brea, CA

Luis Gudiño

Sao Paulo, Brazil

Antonio Bucci

Latina, Italy

Giuseppe Fioravanti

Premier Chemical, Taiwan

Chen Yu-Chuan

UNIROYAL

CHEMICAL

—

## Page 008

ChemWorld 8 January 1991

ChemWorld Briefs

Paraclor® CPE Enters New Markets

Paraclor® CPE, one of Uniroyal Chemical’s specialty elastomers, is proving to be ideally suited for a number of new applications – both customer and plastic. Introduced last year, the elastomer’s versatility is guiding the company into new markets.

One such market is automotive, which takes advantage of the product’s high heat and oil resistance. These characteristics, combined with CPE’s low temperature flexibility and superior outdoor aging properties, make Paraclor CPE a leading candidate for use in injection-molded parts such as air baffle ducts or any under-the-hood hose.

Perhaps the largest slice of the market that Paraclor CPE intends to capture for Uniroyal Chemical is in wire and cable applications, where the product is used as jacketing for flexible cords such as portable power tools as well as for instrumentation, and control and mine cable. The product is easily made flame retardant for such uses, as it meets 60, 90, and 105 degree centigrade UL classifications.

Paraclor CPE also can be used to complement Uniroyal Chemical’s polymer product line, which includes Royalene® EPDM and Pararil® nitrile rubber for traditional markets such as hose, sheeting, gaskets, wire and cable, and roll covers. Used as an impact-modified plastic, Paraclor CPE intends to break through new markets, including wire and cable, with residential and industrial applications.

For example, when two to ten percent of Paraclor CPE is added to vinyl, it serves as an impact modifier for residential applications such as vinyl siding and electrical conduit, lending increased toughness and durability to these applications. The product may be blended with existing vinyl for industrial flat roof coverings to add strength and durability against the elements. Similarly, Paraclor CPE is used as a wire and cable thermoplastic material for jacketing.

Dr. Byron A. Hunter Recipient Of The 1990 Thomas Midgley Award

Dr. Byron A. Hunter, a retired research chemist from Uniroyal Chemical Company, has been named the recipient of the 1990 Thomas Midgley Award sponsored by the American Chemical Society (Detroit section), in cooperation with Ethyl Corporation. The Award was presented to Dr. Hunter at a formal awards ceremony held at the Engineering Society of Detroit, Michigan on Tuesday evening, October 30, 1990.

Founded in 1965, the Thomas Midgley Award, named after the late inventor known for his creative, far-seeing research efforts, is presented annually for outstanding research contributions and inventive genius in the chemistry field related to the automotive industry.

One of the most significant contributions of Dr. Hunter’s career is the development of chemical blowing agents for the production of closed-cell rubber foams used in automotive applications. The commercialization of one type foam (benzene sulfonyl hydrazide) (OBSH) serves as the predominant type of blowing agent used to produce dual durometer weatherstrip. Today, this weatherstrip type comprises about 80 percent of total worldwide use of weatherstrip for automotive and truck seal applications.

Dr. Hunter’s efforts have also increased weatherstrip productivity by 20 percent, due to the lower decomposition temperature and more gas release properties of OBSH.

OSHA also produces a soft textured sponge, which is used in new down-sized and lower weight automotive door and truck lids to facilitate acceptable closing efforts.

Most recently, Dr. Hunter was awarded the 1989-90 Outstanding Achievement Award from the Thermoplastics and Foams Division of the Society of Plastic Engineers (SPE), and is recognized as a leading worldwide authority on blowing agent technology in the areas of rubber and plastics compounds, applications and process technology. To date, he has received 67 United States patents in the rubber and plastic additive fields.

Uniroyal Chemical Introduces New Lubricant Additive

Uniroyal Chemical Company has introduced a new antioxidant lubricant additive, Naugatube® 680, especially formulated for high performance automotive engine and gear oils.

Naugatube® 680 has a high nitrogen content providing advanced performance, lower volatility and improved solubility, which helps meet the most demanding engine specifications.

In the next several months, the company plans to introduce additional high performance lubricant additives, furthering its commitment and responsiveness to the high performance engine oil marketplace.

Current Uniroyal Chemical products that are part of the lubricant additives family include: Naugatube 403, 440, 443, 438, 43SL, 445, 500, 690, and Naugatube® 529, BHT, PANA and Q.

ChemWorld, a publication of Uniroyal Chemical Company worldwide, is distributed to company employees and retirees.

Robert J. Perraudin

Director, Communications

Maureen C. Fama

Marketing Communications Coordinator

Uniroyal Chemical Company

World Headquarters

Middlebury, CT 06749

(203) 573-2000

—