## Page 001

CHEMWORLD

WINTER/SPRING 1995

Published by

Uniroyal Chemical Co.

for its Associates

and Retirees

CONTENTS

2 Logistics Strives for

Continuous Customer

Satisfaction

3 Responsible Care®

Implementation

On Track

4 Annual Total Quality

Recognition Awards

Celebrated

6 International

Advertising Targets

Latin American Markets

7 Novaquim Strengthens

Expansion Efforts

8 Initial Public Offering

Announced

Worldwide Growth Strategy Dictates

New Organization at Uniroyal Chemical

T

o support Uniroyal Chemical’s

continued strategic worldwide

growth, a global organization

has been implemented effective

November, 1994. The realignment replaces the vice president for international operations position with executive vice presidents responsible for

Uniroyal Chemical’s business lines and

operations in three key world regions –

the Americas, Europe and Asia/Pacific.

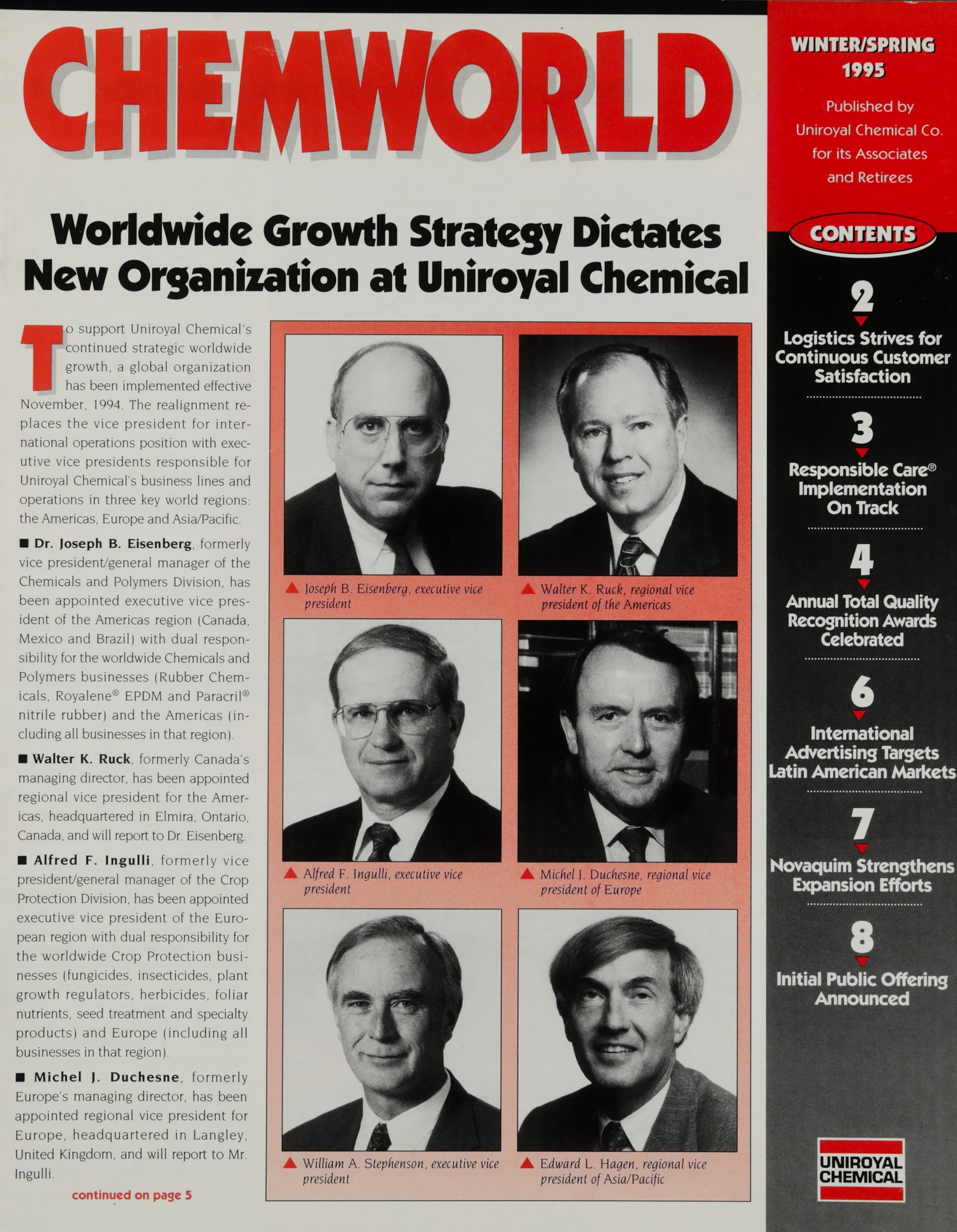

Dr. Joseph B. Eisenberg, formerly

vice president/general manager of the

Chemicals and Polymers Division, has

been appointed executive vice president of the Americas region (Canada,

Mexico and Brazil) with dual responsibility for the worldwide Chemicals and

Polymers businesses (Rubber Chem-

icals, Royalene® EPDM and Paracril®

nitrile rubber and the Americas (in-

cluding all businesses in that region).

Walter K. Ruck, formerly Canada’s

managing director, has been appointed

regional vice president for the Americas, headquartered in Elmira, Ontario,

Canada, and will report to Dr. Eisenberg.

Alfred F. Ingulli, formerly vice

president/general manager of the Crop

Protection Division, has been appointed

executive vice president of the European region with dual responsibility for

the worldwide Crop Protection businesses (fungicides, insecticides, plant

growth regulators, herbicides, foliar

nutrients, seed treatment and specialty

products) and Europe (including all

businesses in that region).

Michel J. Duchesne, formerly

Europe’s managing director, has been

appointed regional vice president for

Europe, headquartered in Langley,

United Kingdom, and will report to Mr.

Ingulli.

continued on page 5

Joseph B. Eisenberg, executive vice

president of the Americas

Walter K. Ruck, regional vice

president of the Americas

Alfred F. Ingulli, executive vice

president of Europe

Michel J. Duchesne, regional vice

president of Europe

William A. Stephenson, executive vice

president

Edward L. Hagen, regional vice

president of Asia/Pacific

—

## Page 002

CHENWORLD

WINTER/SPRING 1995

BRIEFS

Letter Of Intent

Signed To Purchase

Crop Protection

Business Of Solvay

Duphar B.V.

Uniroyal Chemical has signed

a letter of intent to purchase

the worldwide crop

protection business of Solvay

Duphar B.V., headquartered in

The Netherlands. The

business, which has annual

sales of approximately $60

million, includes all crop

protection assets associated

with the production and sale

of Gesarol® fungicide and

Dinit® insecticide. Both of

these products are currently

sold in selected geographic

regions by Uniroyal Chemical

under marketing agreements.

Uniroyal Chemical plans to

continue production at the

Antwerpen plant which is

located near Amsterdam,

subject to the execution of

a definitive acquisition

agreement. It is expected

that the acquisition will be

completed early in 1995.

Logistics Strives For Continuous

Customer Satisfaction

f you ask Uniroyal Chemical’s

Director of Logistics worldwide.

William T. “Bill” Mischou, what he

believes characterizes value-added

customer service today and into the

21st century, you’ll hear a threeword response: Reliability, Resilience

and Innovation.

Reliability is providing the right

products and service at the right price,

delivered as requested by the

customer, in the right quantity

and package, and without

damage. Resilience is the ability

to recover when you do

what you were supposed to do

right in the first place. Innovation means doing more than

just meeting your customers’

basic requests, but also doing

more than what the competition does — in essence, doing

what’s more than expected and

‘delighting’ the customer.

And these three principles

seem to be working. In 1994,

the Logistics Department

successfully managed to keep

inventory levels at a relatively

low percent of the company’s

total sales on a worldwide

basis, while ensuring that

Uniroyal Chemical plants

around the world received the correct

amount of raw materials to manufacture products to meet customers’

needs on a timely basis (on-time

service averaged in the mid-90 percent

range, with the ultimate goal of 100

percent for all businesses). Ironically,

as sales have increased over the last

decade, Logistics has been able to

more effectively service customers

using less inventory each year — a

tribute to the management philosophy

of efficient worldwide teamwork.

“We are constantly facing a balancing act among customer service,

working capital and plant operations,”

stated Mischou. “This means providing

the best possible service to the customer, while simultaneously keeping

working capital costs low through

inventory management, but not so low

that we jeopardize the efficiency of our

plants or lower our on-time delivery

I

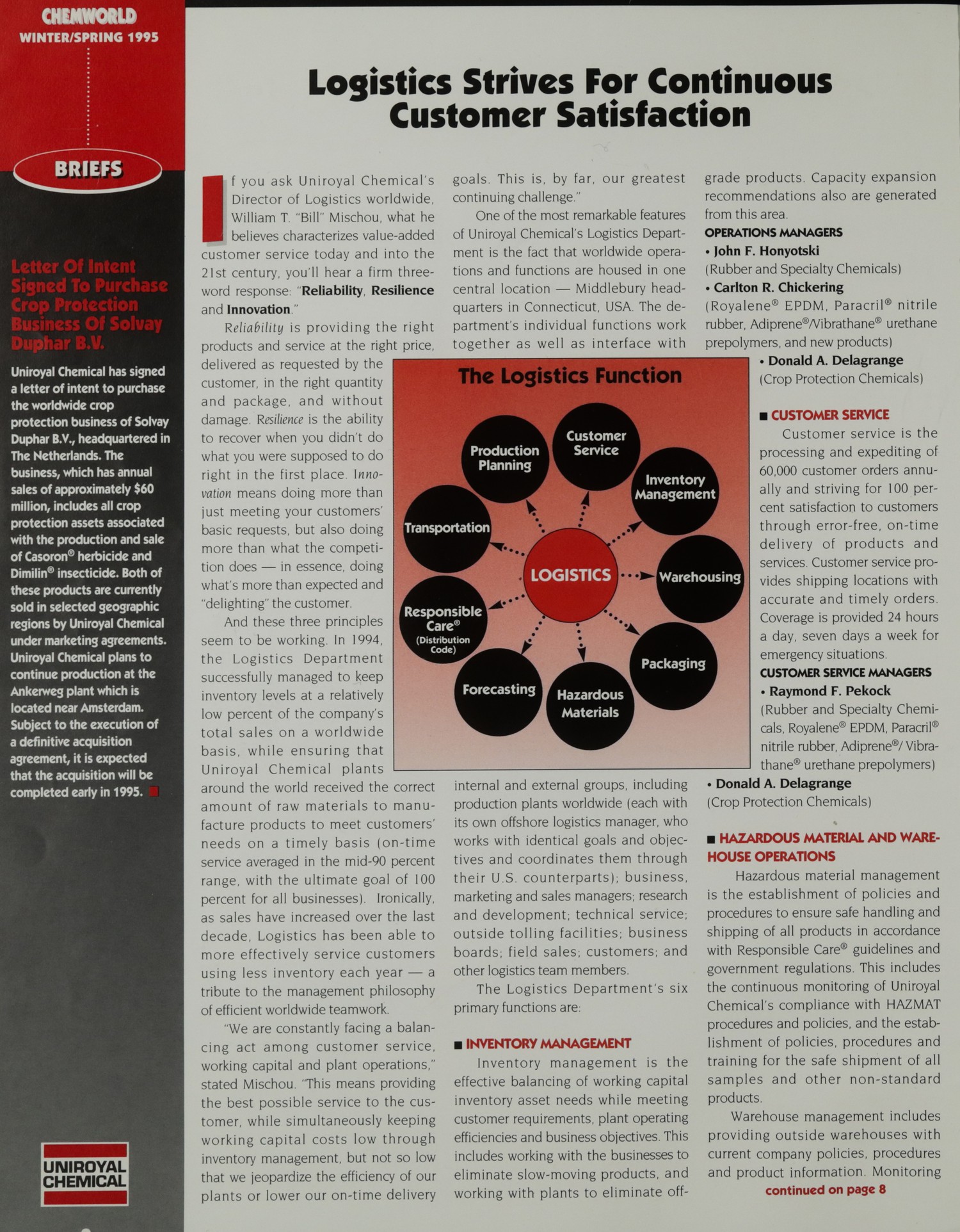

The Logistics Function

Customer

Service

Inventory

Management

Production

Planning

Forecasting

Responsible

Care*

(Distribution

Code)

Transportation

Warehousing

Packaging

Hazardous

Materials

goals. This is, by far, our greatest

continuing challenge.”

One of the most remarkable features

of Uniroyal Chemical’s Logistics Department is the fact that worldwide operations and functions are housed in one

central location — Middlebury headquarters in Connecticut, USA. The department’s individual functions work

together as well as interface with

internal and external groups, including

production plants worldwide (each with

its own offshore logistics manager, who

works with identical goals and objectives and coordinates them through

their U.S. counterparts), business,

marketing and sales managers, research

and development, technical service,

outside tolling facilities, business

boards, field sales, customers, and

other logistics team members.

The Logistics Department’s six

primary functions are:

INVENTORY MANAGEMENT

Inventory management is the

effective balancing of working capital

inventory asset needs while meeting

customer requirements. Plant operating

efficiencies and business objectives. This

includes working with the businesses to

eliminate slow-moving products, and

working with plants to eliminate off-

LOGISTICS

grade products. Capacity expansion

recommendations also are generated

from this area.

OPERATIONS MANAGERS

• John F. Honotski

(Rubber Specialty Chemicals)

• Carlton R. Chickering

(Royalenea EPDM, Paracril® nitrile

rubber, Adiprene® Vibrachem® urethane

prepolymers, and new products)

• Donald A. Delagnge

(Crop Protection Chemicals)

CUSTOMER SERVICE

Customer service is the

processing and expediting of

60,000 customer orders annually and striving for 100 percent satisfaction to customers

through error-free, on-time

delivery of products and

services. Customer service provides shipping locations with

accurate and timely orders.

Coverage is provided 24 hours

a day, seven days a week for

emergency situations.

CUSTOMER SERVICE MANAGERS

• Raymond F. Pelock

(Rubber and Specialty Chemicals, Royalenea EPDM, Paracil®

nitrile rubber, Adiprene® Vibrachem® urethane prepolymers)

• Donald A. Delagnge

(Crop Protection Chemicals)

HAZARDOUS MATERIAL AND WAREHOUSE OPERATIONS

Hazardous material management

is the establishment of policies and

procedures to ensure safe handling and

shipping of all products in accordance

with Responsible Care® guidelines and

government regulations. This includes

the continuous monitoring of Uniroyal

Chemical’s compliance with HAZMAT

procedures and policies, and the establishment of policies, procedures and

training for the safe shipment of all

samples and other non-standard

products.

Warehouse management includes

providing outside warehouses with

current company policies, procedures

and product information. Monitoring

continued on page 8

—

## Page 003

Here is the text extracted from the document image, preserving the layout and structure as much as possible:

Responsible Care® Implementation On Track

As Uniroyal Chemical’s Responsible Care® Coordinator, Joseph V. Bucciaglia is in the process of visiting Uniroyal Chemical locations to help implement the company’s Responsible Care program. In 1995, Bucciaglia’s goal is to oversee worldwide implementation of “Management Practice in Place,” which provides standards against which to measure performance. Management Practice In Place standards must be developed and documented for each of the Responsible Care® program codes. Standards have been finalized for all of the codes, except Product Stewardship, and Uniroyal Chemical plans to have the Pollution Prevention, Process Safety, Distribution and CAER (Community Awareness/Emergency Response) codes implemented by November 1995. The remaining codes are slated for implementation by April 1997.

The CAER Code relates directly to one of Uniroyal Chemical’s corporate goals “Build Strong Community Partnerships”. One aim of the code is to establish a dialogue between the company and the public. The other codes help to support another Uniroyal Chemical goal, “Zero Damage to People and the Environment.” These codes help to improve performance and ensure that industry operations will work towards improving the health and safety of the public, workers and the environment. Some each of the seven codes have been implemented. The CMA will conduct a validation of the program. The validation process will require that detailed records of all related programs are kept.

Bucciaglia would like to see that documentation compiled in a format similar to what is currently being used for ISO certification. In addition, each reporting site will also be required to complete a self-evaluation of its program.

Uniroyal Chemical was not the first company to begin implementation of the Responsible Care program, but Bucciaglia sees a benefit in not being a front-runner. We’ve definitely taken advantage of other’s experiences – both good and bad.

PROGRAM STATUS

CODES Practice-in-Place Standards for Management Practices have been finalized for 6 of the 7 codes. (Product Stewardship is the exception.)

DOCUMENTATION In order to prepare for eventual verification, a systems procedure similar to ISO 9000 is being prepared to assist in controlling documentation as it is finalized.

SELF-EVALUATIONS Definitions for each of the six evaluation categories have been issued for use by each reporting site.

VERIFICATION CMA has begun a trial of its proposed verification system and is expected to start late 1995 or 1996.

BRIEFS

License Agreement Signed with Japan Synthetic Rubber

Uniroyal Chemical recently signed a license agreement with Japan Synthetic Rubber Co., Ltd. (JSR), a Tokyo-based chemical company which manufactures and markets synthetic rubber worldwide. This agreement allows Uniroyal Chemical to receive technology from JSR to manufacture and market certain acrylonitrile-butadiene rubber (NBR) products in the United States. “This agreement will help support our ParacrilTM NBR business by strengthening our technology and product line,” said Jeffrey M. Limes, business director for ParacrilTM. “We will be able to better satisfy the needs of our current customers, while expanding our development of new market areas. Furthermore, we look forward to our relationship with JSR as having a mutually supportive impact on each company.”

“We are delighted that we will be able to provide JSR quality products, in co-operation with Uniroyal Chemical, to customers in the United States including the Japanese transplants,” said T. Katada, general manager of the Synthetic Rubber Division II of JSR, the largest producer of synthetic rubber in Japan and the fourth largest synthetic rubber producer worldwide, also manufactures emulsions and ABS resins for worldwide markets.

—

## Page 004

CHEMWORLD

WINTER/SPRING 1995

BRIEFS

New Sales Agent

Named For Polymer

Modifier Business

Uniroyal Chemical has assigned

a new sales agent, Velox

Trading GmbH, to market and

sell Poly Bond* and Royalene*

polymer modifier products to

both the packaging and

custom compounding markets,

effective August 1,1994.

Velox Trading GmbH, based

in Hamburg, Germany, will

market and sell Uniroyal Chemical’s

complete polymer modifiers

product line in Germany,

France, Switzerland, Austria,

Belgium, and The Netherlands

through their facilities located

in Hamburg and Paris, France.

Malcolm Jackson, Uniroyal

Chemical Ltd.’s European marketing manager for Polymer

Modifiers and Specialty

Chemicals said, “Velox will

help our sales expansion in

Europe by servicing the market

with knowledgeable and

dedicated people, backed by

Uniroyal Chemical’s strong

technical resources. This will

allow us to continue to

support our existing customer

base while focusing on new

market opportunities.”

Poly Bond products are

acrylic acid-or maleic anhydride

grafted polyolefins used as tie

layers in multi-layer packaging

coupling agents for glass filled

polyca rbonates; com pounds;

and compatibilizers for polyolefin polymer blends and alloys.

Royalene products are maleic

anhydride or SAN grafted ethylene propylene elastomers used

as tougheners for engineering

thermoplastics (polyamides,

polycarbonate, PBT and PET);

compatibilizers for polar and

non-polar (prime and recycled)

polymer blends and alloys; and

impact modifiers for weatherable polymer systems.

Annual Total Quality Recognition Awards

Celebrated

n November 10,1994 in Southbury, Connecticut, USA, Uniroyal Chemical’s Chairman,

President and CEO Robert J. Mazaika presented the year’s Total Quality Recognition

Awards and Lifetime Career Achievement Award to the following associates:

RAMAN IYER

In July 1993, a tank truck filled with

Naugard* I-5-Vinyl Toluene exploded in

Port Allen, Louisiana, USA and Uniroyal

Chemical’s Manager of Environmental Engineering,

Raman Iyer, was

sent to the site. Raman managed the

company’s Emergency Response

team and oversaw

the massive cleanup effort, even though the cause of the

incident and the potentially liable parties

had not yet been identified.

Working closely with an independent contractor, Louisiana state and local

officials, and others, Raman supervised

the clean-up, while handling this

potentially devastating project efficiently and cost-effectively. Through skillful

negotiation and a keen knowledge of

regulations, Raman was able to limit

site remediation costs substantially,

and helped to save millions of dollars

by averting out-of-state incineration

costs.

Raman’s professionalism and concern

for the environment is great testimony

to Uniroyal Chemical’s corporate goal of

“Zero Damage to People and the Environment.” His actions also helped to

increase the company’s visibility among

Louisiana authorities, showing Uniroyal

Chemical as a responsive member of

CMA’s Responsible Care® program.

NELSON PORTER

A determination to

create new sales

opportunities in his

territory in 1994 led

Nelson

Porter,

Uniroyal Chemical’s

senior technical

sales representative

for Crop Protection

located in Raleigh,

North Carolina, USA to target both

growers and distributors for a new

pump program involving liquid Terracior* TSX-EC. He designed an improved pump model, which the manufacturer of the existing model agreed to

put into his line. Nelson then personally met with the most influential growers

to introduce them to the new pump

program and benefits of a liquid system.

By the time the selling season arrived,

Nelson’s pump program had already been

adopted by the majority of growers he

called on, and TSX-EC filled virtually

every distributor warehouse in his region.

The results of Nelson’s actions were

a sizable gain in market share from

Uniroyal Chemical’s key competitor, an

increase in Terracior TSX-EC sales by

58% percent over 1993, and gained

support of distributors who had not

been committed to Uniroyal Chemical/

Terracior products in the past.

Nelson’s efforts have truly established Uniroyal Chemical as the “Supplier

of Choice” in the Crop Protection

business.

Team members found creative ways to

improve safety, productivity and quality

– and reduce scrap – while keeping implementation costs at a fraction of the

annualized savings.

One of the team’s major projects,

“Roylene* Poly lil Slurry Crossover”, was

selected to represent Geismar in the 1994

Association for Quality and Participation (AQP) National Team Excellence

Award competition. Polytrio received

first place in their region, and scored

among the top five teams, from a total

field of 18, in national competition.

The Polytrio Quality Circle has

demonstrated true team-based excellence in support of Uniroyal Chemical’s

corporate goal of “Total Associate

Involvement.”

LIFETIME CAREER ACHIEVEMENT

RECIPIENT

Eli Schwartz, director of Technology Acquisition and Licensing, located in

Middlebury, Connecticut, USA, is this

year’s recipient of Uniroyal Chemical’s

prestigious Lifetime Career Achievement Award.

As a 43-year career professional, Eli

has been instrumental in developing

global markets through innovative

technology development and licensing.

He developed a first-of-its-kind technology exchange program with Bayer in

Germany and helped to establish the

company’s joint venture with Sumitomo

Chemical in Japan, which continues

today as a strong technical and business partnership.

Eli’s outstanding combination of

global perspective, technical background

and business savvy, has led Uniroyal

continued on page 7

—

## Page 005

Worldwide Growth Strategy Dictates New Organization

(continued from page 1)

William A. Stephenson, formerly vice president/general manager of the Specialties Division, has been appointed ed executive vice president of the Asia/Pacific region with responsibility for the worldwide Specialties businesses (Adhesive*/Vibrathane* urethane prepolymers and Specialty Chemicals), Gustafson (a wholly-owned subsidiary for seed treatment chemicals in Asia/Pacific (including all businesses in that region).

Dr. Edward L. Hagen has been appointed regional vice president for Asia/ Pacific and will report to Mr. Stephenson. The headquarters location will be announced shortly.

“This new global organization structure will help support a firm foundation for shared leadership, constructive interdependence between divisions and regions, and matrixed teamwork at all management levels,” commented Robert J. Majarika, Uniroyal Chemical’s chairman, president and CEO. “We are looking forward to an even more successful future as we become a stronger player in the global chemical industry.”

PROFESSIONAL PROFILES

Dr. JOSEPH B. EISENBERG

Dr. Joseph B. Eisenberg has been with Uniroyal Chemical for over 30 years, serving as senior group leader, production superintendent for polymers, production superintendent for chemicals, technical superintendent, engineering manager, and general manager of international operations for Chemicals and Polymers. Most recently, he was vice president and general manager of the Chemicals and Polymers Division, responsible for Royalene* EPDM and Paracril* nitrile rubber.

Dr. Eisenberg received a B.S., M.S. and Ph.D in chemical engineering from Clarkson University in New York, USA.

WALTER K. RUCK

Walter K. Ruck joined Uniroyal Inc. in 1979 as manager of construction in the Chemical Division Engineering Department. He progressed through a number of managerial positions since that time and was transferred to Uniroyal Ltd. in Elmira, Ontario, Canada in 1985, where he served as manager of manufacturing.

Since 1988, he has held the position of managing director/general manager of Uniroyal Chemical Ltd. in Elmira.

Mr. Ruck has a B.S. in engineering from Christian Brothers College in Memphis, Tennessee, USA and attended St. Louis University in St. Louis, Missouri, USA. He has also pursued graduate studies in business management at Xavier University in Cincinnati, Ohio, USA.

ALFRED F. INGALLI

Mr. Ingalli has been with Uniroyal Chemical for 31 years, and has worked in research and development where he was awarded two patents for high temperature thermoplastic alloys. He also worked in market development where he was instrumental in establishing two new businesses — Polyme®* dispersants and Synton* synthetic lubricants. He has also served as business manager for many of the company’s businesses in the Chemicals and Polymers Division and Specialties Division.

Most recently, he was vice president and general manager of the Crop Protection Division, responsible for fungicides, insecticides, plant growth regulators, herbicides, foliar nutrients, seed treatment and other crop protection specialty products worldwide.

Mr. Ingalli received a B.S. in chemical engineering from Polytechnic Institute and an M.S. in management from Rensselaer Polytechnic Institute, both located in New York, USA. He also completed the Harvard Business School Program of Management Development.

MICHEL J. DUCHESNE

With a background in international and general management, having worked for regional, national and international sales divisions for both Uniroyal Chemical and other Fortune 500 companies, Mr. Duchesne has been general sales manager of the Crop Protection International Division and general sales manager and director of sales of the Crop Protection Division worldwide.

Most recently, he served as managing director of European operations based in Langley, United Kingdom.

A native of France, Mr. Duchesne holds a dual French-American citizenship. He received a B.A. and an M.S. in agronomy from the National Institute of Agronomy at the University of Paris, France.

WILLIAM A. STEPHENSON

A 26-year veteran of Uniroyal Chemical, William Stephenson has worked as a development engineer in research and development, technical sales service representative, manager for Paracril nitrile rubber, and marketing manager and business manager for Royalene EPDM.

Most recently, he was vice president and general manager of the Specialties Division, overseeing two key business units: Adhesive*/Vibrathane urethane prepolymers and Specialty Chemicals – a major supplier of plastics additives including antioxidants, foaming agents, epoxy curatives and polymerization inhibitors, as well as lubricant additives and intermediates.

Mr. Stephenson received a B.S. in plastics technology from Lowell Technological Institute in Lowell, Massachusetts, USA, and an M.B.A. in marketing from the University of Hartford, Connecticut, USA.

Dr. EDWARD L. HAGEN

Dr. Edward L. Hagen started his career in 1969 as a research chemist in corporate R&D for Uniroyal Inc., and then joined Uniroyal Chemical in 1974 as a technical sales service group leader for Vibrathane castable urethanes and Royler* thermoplastic urethanes. He continued his career in the urethanes area as R&D and technical sales service manager, marketing specialist and worldwide business manager through 1991.

Most recently, he held the position of vice president of Corporate Business Development. Dr. Hagen received a B.S. in chemistry from the University of Notre Dame in South Bend, Indiana, USA and a Ph.D. in organic chemistry from Yale University in New Haven, Connecticut, USA.

BRIEFS

Seed Treatment Operation in United Kingdom Acquired

Uniroyal Chemical has purchased the seed treatment operation of Dowelanco in the United Kingdom and Ireland. The transaction was completed on November 3, 1994.

“Uniroyal Chemical already is the global leader in seed treatment products and technology, and this acquisition enables us to bolster our key market,” said Alfred F. Ingalli, executive vice president responsible for the company’s Crop Protection product lines.

“Dowelanco customers in the United Kingdom can expect a continued strong commitment to seed treatment products, equipment and service,” the transaction includes the existing Dowelanco seed treatment team, development, equipment, machinery and spare parts inventory. Dowelanco announced last year that the divestiture would enable it to focus on its core business.

Uniroyal Chemical’s Crop Protection business continued to grow in 1994, especially in the area of seed treatment,” Ingalli said. “Our personnel, products and expertise make us the dominant leader in seed treatment, both in North America and worldwide.”

—

## Page 006

Here is the text extracted from the document image, preserving the layout and structure as much as possible:

CHEMWORLD

WINTER/SPRING 1995

BRIEFS

Rights to Biological

Insecticide Acquired

Uniroyal Chemical has acquired

exclusive marketing rights for

BIOCOT® insecticide on cotton,

soybeans and peanuts. BIOCOT is a highly selective

Bacillus thuringiensis (Bt) insect-

icide specific for the control of

lepidopterous larvae. BIOCOT is

produced by Novo Nordisk of

Copenhagen, Denmark, one of the

world’s leading biotechnology

companies.

“Because of recent changes in

pest management practices and

the insect spectrum—especially

in the cotton market—Uniroyal

Chemical believes conditions are

better than ever for an effective

Bt insecticide,” said Keith Kelley,

Crop Protection marketing man-

ager for insecticides and acaricides.

“First, more growers are adopting

an integrated approach to pest

management. Unlike many chem-

ical insecticides, BIOCOT is an

ideal product in an integrated pro-

gram because it targets specific

pest species and helps preserve

beneficial insects,” he said.

“Second, due to its unique

mode of action, BIOCOT is an

excellent partner with pyrethroids

in a coordinated resistance man-

agement strategy,” Kelley added.

“Third, the Heliothine complex

in cotton has shifted toward but-

worms, where BIOCOT is highly

effective,” he said.

BIOCOT contains spores and

active protein crystals produced

by the naturally occurring bacte-

rium Bacillus thuringiensis, subspe-

cies kurstaki. BIOCOT controls lepid-

opterous larvae such as army-

worms, loopers, bollworms, bud-

worms and velvetbean caterpillars

on cotton, soybeans and peanuts.

Without question, American

farmers will continue to fine-tune

the way they control pests,

Kelley said. “Uniroyal Chemical is

committed to providing products

such as BIOCOT that will help

them do so effectively and eco-

nomically.”

BIOCOT is a trademark of

Novo Nordisk.

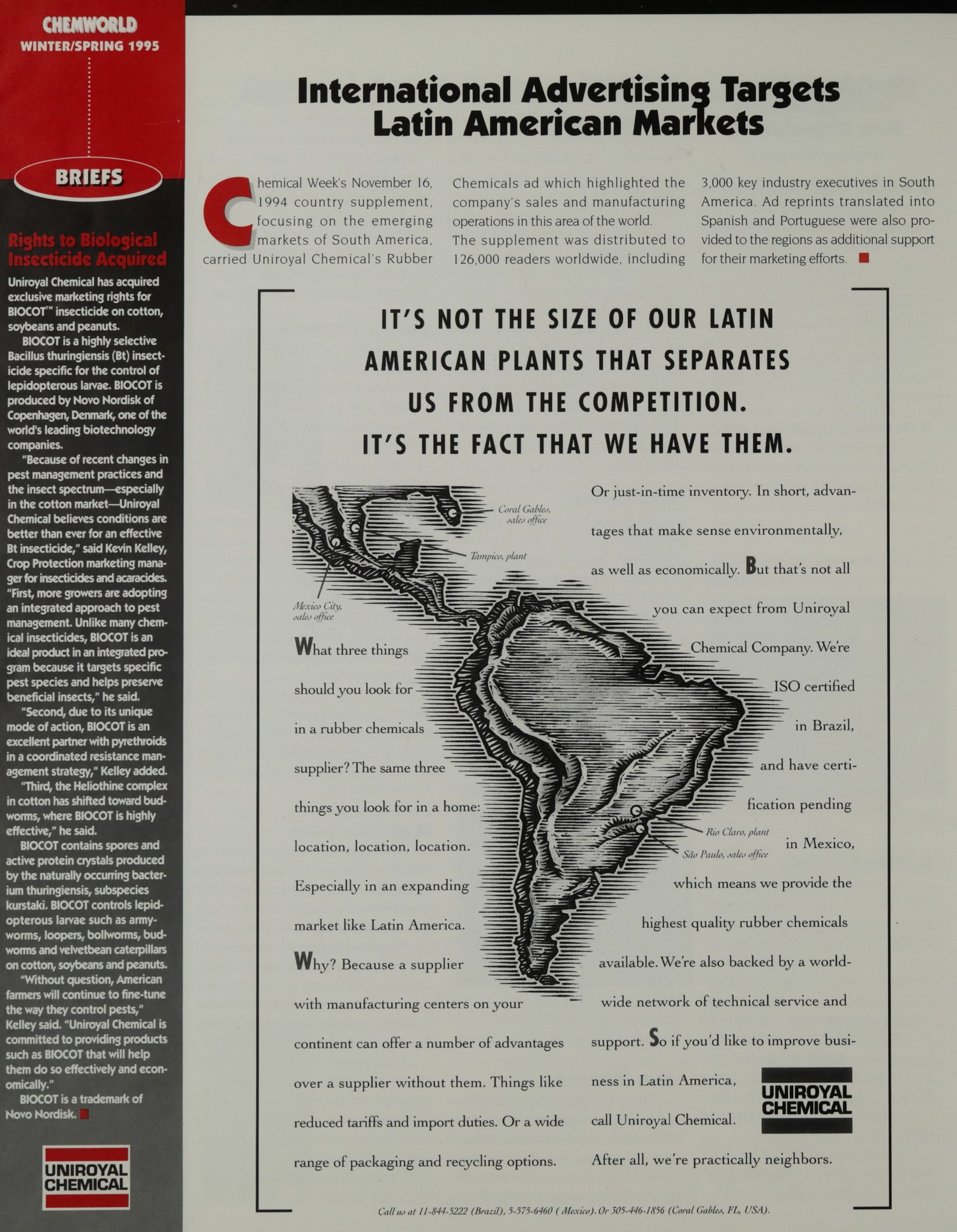

International Advertising Targets

Latin American Markets

C

hemical Week’s November 16,

1994 country supplement,

focusing on the emerging

markets of South America,

carried Uniroyal Chemical’s Rubber

ad, which highlighted the

company’s sales and manufacturing

operations in this area of the world.

The supplement was distributed to

126,000 readers worldwide, including

Chemicals ad which highlighted the

company’s sales and manufacturing

operations in this area of the world.

The supplement was distributed to

126,000 readers worldwide, including

3,000 key industry executives in South

America. Ad reprints translated into

Spanish and Portuguese were also pro-

vided to the regions as additional support

for their marketing efforts.

IT’S NOT THE SIZE OF OUR LATIN

AMERICAN PLANTS THAT SEPARATES

US FROM THE COMPETITION.

IT’S THE FACT THAT WE HAVE THEM.

Or just-in-time inventory. In short, advan-

tages that make sense environmentally,

as well as economically. But that’s not all

you can expect from Uniroyal

Chemical Company. We’re

ISO certified

in Brazil,

and have certi-

fication pending

in Mexico,

which means we provide the

highest quality rubber chemicals

available. We’re also backed by a world-

wide network of technical service and

support. So if you’d like to improve busi-

ness in Latin America,

call Uniroyal Chemical.

After all, we’re practically neighbors.

Call us at 1-800-222 (Brazil), 5-575-6480 (Mexico), 08-505-46.1856 (Carol Gables, FL USA).

What three things

should you look for

in a rubber chemicals

supplier? The same three

things you look for in a home:

location, location, location.

Especially in an expanding

market like Latin America.

Why? Because a supplier

with manufacturing centers on your

continent can offer a number of advantages

over a supplier without them. Things like

reduced tariffs and import duties. Or a wide

range of packaging and recycling options.

—

## Page 007

Novaquim Strengthens Uniroyal Chemical’s Expansion Efforts

When Uniroyal Chemical fully acquired Novaquim SA de CV in Mexico from its former joint venture partner Cydsain July 1993, it hailed the event as a “milestone in the company’s drive toward globalization” and a sign of its “solid commitment to a worldwide customer base and to specialty rubber chemicals, polymers, and urethane markets in Mexico.” Today, Novaquim is proving itself to be more than just a milestone and symbol of commitment.

Under the leadership of Managing Director Rodolfo Montemayor, Novaquim is a pivotal manufacturing organization which allows Uniroyal Chemical to position itself more strongly to serve Mexico and Latin American markets.

Since the early 1970s, Novaquim has continued to build an outstanding reputation in Mexico as a producer of superior quality products,” said Montemayor. “Our customers continually put our products to the test, and they demand that our products meet the most stringent quality standards for performance. The feedback we’ve received indicates that we’re achieving the highest levels of satisfaction with our customers. We are very proud of this achievement.”

Novaquim is primarily engaged in the manufacture of specialty rubber chemicals for the tire and rubber processing markets, and since 1985, specialty chemicals and polyurethanes for the plastics, petroleum, food additives and recreational markets. Among the key products manufactured at Novaquim’s Tampico facility are a broad range of antioxidants, antiozonants, and other rubber additives such as Novalene® AS, Tlex Thiram®, Naugard® P/HR, Flexzone® 7F, BLE® 25 and Nausurf S.

The Tampico plant, which currently employs almost 100 associates (48 additional associates work at Novaquim’s Mexico City sales office), has helped Uniroyal Chemical meet its goal of establishing research, production, and marketing support capabilities in Latin America, and further enhances the company’s plans to build upon its international presence.

Since the acquisition of Novaquim, the United States, Mexico and Canada have entered the North American Free Trade Agreement (NAFTA), which has opened new doors for increased growth. According to Montemayor, “Among NAFTA’s brightest promises are the opportunities it creates for the growth of the automotive industry in Mexico.” This will particularly benefit both Novaquim and Uniroyal Chemical as a supplier in this market will be reinforced by increased demand for specialty rubber chemicals among tire manufacturers.

Looking ahead, Montemayor also notes that Mexico is signing free-trade agreements with countries in Central and South America as well. “I believe that Uniroyal Chemical’s presence in Mexico through Novaquim will put the company in a unique position to make further in-roads into these Central and South American markets,” said Montemayor. “These markets hold so much potential in the near term.”

And Novaquim places Uniroyal Chemical one closer than the competition to these opportunities—not only in terms of geography, but also in capabilities and valuable knowledge of the culture and business environment. This can only help Uniroyal Chemical to successfully continue the momentum of its expansion efforts.

Annual Total Quality Recognition Awards Celebrated

Chemical to a strong place in the global chemical community – as evidenced by his successful role in licensing the company’s technology for ABS, TPR, LATEX, ROVAL® POLYOLEFINE® and Crop Protection chemicals to companies around the world.

After recognizing the emergence of Japan as a significant source of technology, Eli put into place valuable monitoring systems to identify new technologies important to Uniroyal Chemical. He has also worked closely with the former Soviet Union, and more recently, with China to advocate joint ventures and licensing agreements to help strengthen the company’s global position.

In 1992, Eli was honored as the recipient of Uniroyal Chemical’s Robert W. Brown Award, which recognizes associates who have shown technical excellence, enthusiasm and high ethical standards throughout their careers. Eli’s global vision, intrinsic understanding of the importance and value of changing technology, and an admired honesty and integrity which permeates all his business relationships have contributed to his lifelong success.

Briefs

– USDA Authorizes Fireban™ for Imported Fire Ant Control

– Uniroyal Chemical has announced that the use of Fireban™ Insecticide has been approved by the Animal and Plant Health Inspection Service for use as a soil treatment for the control of imported fire ants in the Imported Fire Ant Quarantine Program and/or the Imported Fire Ant Free Nursery Program.

– Long residual insecticides blended into nursery potting media is one of the most cost-effective measures for preventing the spread of imported fire ants in nursery stock,” said Homer Collins, Fire Ant Station Leader, USDA.

– The USDA’s final ruling, published in the Federal Register, provides for the immediate use of Fireban in soil media for containment and balled-and-burlapped ornamentals certified for interstate movement from quarantine areas.

– More than 2,600 greenhouse and nurseries throughout most of the South are affected by this ruling.

– According to Laureen Treu, business director for Uniroyal Chemical’s Specialty Chemical’s Crop Protection Division, “Fireban is a highly-effective insecticide giving consistent control of imported fire ants. The USDA action gives producers of ornamental plants in quarantine areas a cost-effective alternative in treating soil and potting media to prevent the infestation and spread of imported fire ants.”

– USDA authorized use rates may from 10 pounds to 25 pounds per cubic yard, depending on the desired length of certification.

– Fireban must be used in accordance with all USDA guidelines established for the Imported Fire Ant Free Nursery Program.

– A synthetic pyrethroid insecticide, Fireban is a granular product containing 15% of the active ingredient fipronil, which will be available in 50 lb. bags. Fireban is a trademark of a Zeneca Group Company.

—

## Page 008

BRIEFS

WACA Recognizes Uniroyal Chemical

ASSOCLATE for

Outstanding Service

Ray Parker of Uniroyal Chemical

has recently been honored by

the Western Agricultural Chemicals Association for outstanding

service to the organization and

industry.

Parker, product development

representative, was named the

WACA Outstanding Member for

1994. He was presented with the

award at WACA’s 65th Annual

Meeting in October, 1994 and is

the sixteenth person to receive

the award since 1979.

“We’re thrilled to have someone like Ray active in the association,” said Steve Fosmore, WACA

executive director. “He took the

Legislative Action Program and

put his heart and soul into it. It’s

one of the most effective grassroots programs in the country.”

It’s an award well-deserved – to

be an asset to the entire industry.

In addition to the Legislative

Action Program, Parker has been

active on the California State

Action Committee and the

Environment Affairs Committee.

WACA represents manufacturers, formulators, distributors

and retailers of pest management products and services in

nine Western states. The association’s objective is to promote a

positive business climate and

industry goodwill. WACA has

approximately 200 member

companies with 1,000 active

participants.

Uniroyal Chemical Corporation Announces

Filing of Initial Public Offering

niroyal Chemical Corporation, Incorporated will be the representatives

the parent company of Uniof the underwriting syndicate for the

royal Chemical Company, Inc.,

offering. The company intends to

announced on December 16,

proceed to the Company and

1994 that it has filed with the Securities

up to an additional $40 million to

and Exchange Commission a Regisretire indebtedness.

tration Statement relating to a proSubject to market conditions and

posed $200 million initial public offerview other factors, the Company anticipates

ing of its common stock. Smith Barney

that the proposed offering could occur in

Inc., Morgan Stanley & Co. Incorporthe first calendar quarter of 1995. There

ated, and Wertheim Schroder & Co.

can be no assurance that such favorable

U

CHEMWORLD

is published twice a year by

Uniroyal Chemical Company, Inc.

for its associates and retailers.

Robert J. Petrusch

Director, Communications

Maureen C. Fama

Manager, Communications Programs

Uniroyal Chemical Company, Inc.

World Headquarters

Benson Road

Middlebury, CT 06749

(203) 573-3000

Logistics Strives for

Continuous Customer

Satisfaction

(continued from page 2)

warehouse performance helps to

ensure that specific goals for on-time

shipments, customer pickup turn around

time, and inventory accuracy are met.

HAZMAT AND WAREHOUSE OPERATIONS

MANAGER

• Henry D. Davies

PACKAGING

The packaging function is responsible for developing quality packages

and labels, which must maintain

product integrity, and exceed customer

business and “Responsible Care” requirements. They must also be disposable, recyclable or source-reduced to

ensure regulatory compliance. This

includes establishing and maintaining

a global package code system for easier

tracking and identification purposes.

In 1994 primarily through the

efforts of the company’s Packaging

Excellence team, total package landfill

elimination amounted to over 5.1

million pounds, with a cost savings to

Uniroyal Chemical of almost $1.3

million. Active programs emphasizing

customer partnerships are continually

being pursued and improved upon.

PACKAGING PROGRAM MANAGER

• Morris L. Beaver

TRANSPORTATION

Transportation’s goal is to maintain

an efficient, responsible global trans-

market conditions will exist in the first

quarter of 1995.

A Registration Statement relating to

the proposed offering of the new common stock has been filed with the Securities and Exchange Commission but has

not yet become effective. None of the

new common stock may be sold, nor may

offers to buy the new common stock be

accepted, prior to the time the Registration Statement becomes effective.

company’s Total Quality Recognition

Program. Department associates have

also received seven Total Quality “Gold

Coin” awards and five “President’s

Awards” for their outstanding efforts.

The Logistics Department continues to meet multiple Uniroyal Chemical corporate goals in its daily activities:

“Total Associate Involvement,” “Supplier

of Choice,” “Low Cost Producer of Products and Services,” and “Zero Damage

to People and the Environment.” The

department is heavily involved in

developing and implementing the Distribution Code of Management Practices (MIST) code (as defined) as part

of the Responsible Care program

initiated by the Chemical Manufacturers Association (CMA). The company

is expected to have this code in place

by November 1995.

And what sort of challenges will

Logistics face in the future?

According to Mischow, there are

three key areas which will expand the

complexities associated with handling

and distributing products worldwide:

an increase in regulatory compliance;

environmental issues (protection of

people and the environment); and everincreasing customer expectations.

The area of customer expectations

will present the biggest challenge.

Customer needs are constantly changing, and they will be looking for a supplier who is flexible enough to change

along with them, but who also can help

contribute to their growing success.

“I’m confident that we’ll do whatever it

takes to be that supplier — and do it

without skipping a beat,” he concluded.

GENERAL TRAFFIC MANAGER

• Ralph E. Buonocore

FORECASTING

Forecasting provides reliable demand forecasts to be utilized to ensure

proper inventory and support business

planning. This includes monitoring the

accuracy of the product forecasts by

business on a monthly basis, as well as

providing one total forecast for Uniroyal

Chemical on a global basis.

PLANNING SUPERVISOR

• Michael J. Rasa

Within Uniroyal Chemical, the

Logistics Department has been a major

contributor to the company’s “Committed to Excellence” programs. Logistics

associates now chair the Chemicals and

Polymers and Specialties Packaging,

Domestic On-Time, Export On-Time,

and Crop Documentation Excellence

Teams, and serve on many other

Excellence Committees. Logistics associates are also very involved in “Where

Do I Fit In Quality?” and have been

recognized numerous times through the

—