## Page 002

Here is the extracted text from the document image:

What happened in September?…

Was it a letdown after the long, hot summer? Was it a relaxation of attitude because of our improved performance over last year? Was it a little anticipation of attaining rewards for goals that have not quite been reached, but were close?

What happened in September? Those incidents in the month were the worst performance this year. Were we do wrong?

The answer to that question lies not in history, but in the future. What’s done is done, but let us learn from this recent experience and firm up our attitudes on Safety. We must strengthen our resolve to think safe and anticipate the unexpected. And follow rules, procedures, and good common sense to ever further levels of accomplishment. We must work closer together, and help each other to solve the accident problem.

92 Take “Life” Course

In Silver

$3500 Dollars

September Safety

Record Poor

The Summer Safety program for the summer months ended on September 30, 1973 was regarded as poorer when compared to employees lost time accidents from July, August and September months in 1972, no accidents increase.

People who worked without a Lost Time Accident or Serious Injury received a “silver dollar” for each month, unless they were members of a Group in which one person incurred either type of injury.

Extra Award

Each employee also received an extra “silver dollar” if he worked the full 3 months without an injury, whether or not a member of his Group suffered one.

Employees who worked during the single program without an injury received the usual “silver dollar” when the thermometer showed the 3 hottest days for one of the hotest summer days and when accidents are more likely to happen.

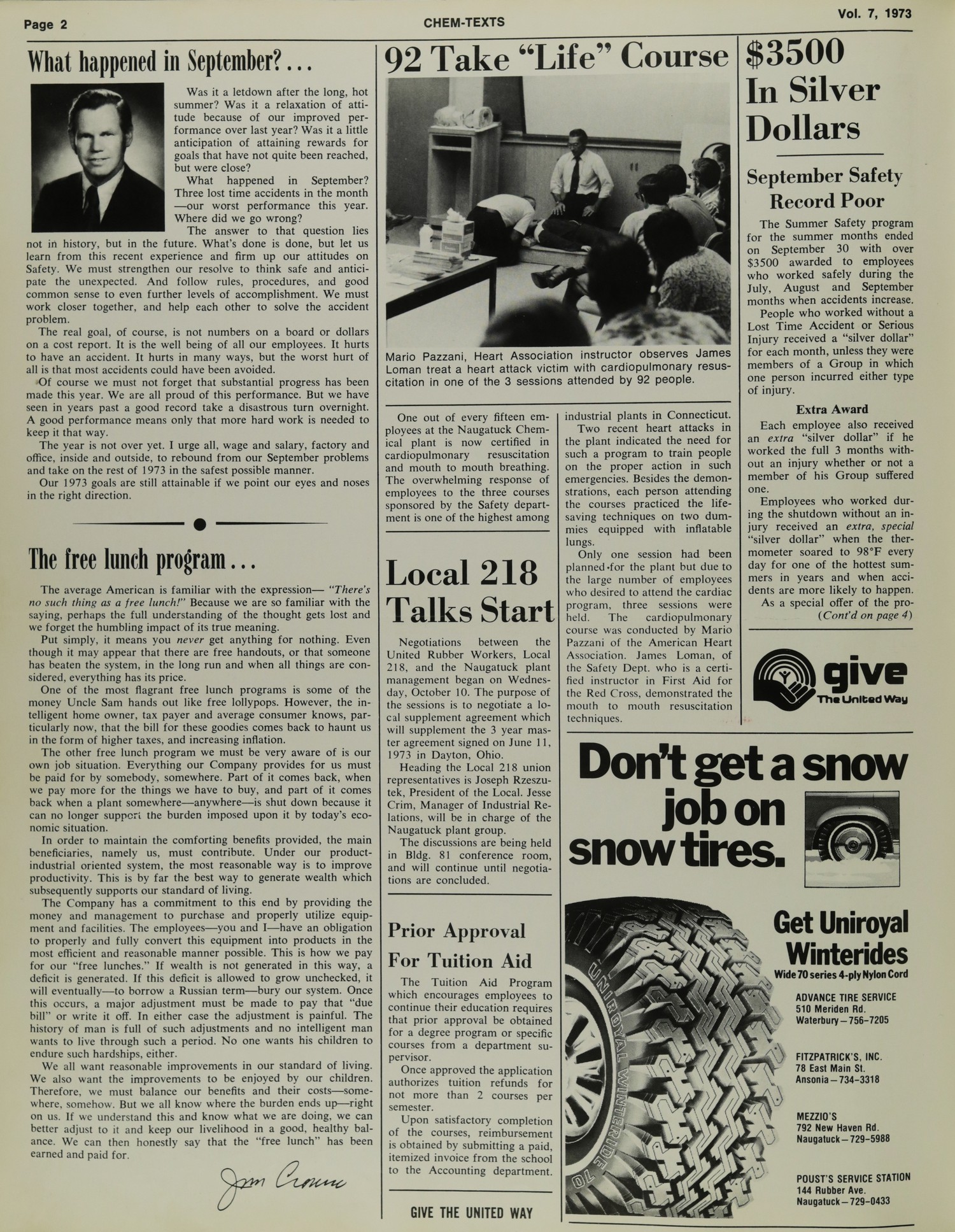

Mario Pazzani, Heart Association instructor observes James Loman treat a heart attack victim with cardiopulmonary resuscitation in one of the 3 sessions attended by 92 people.

“One out of every fifteen-em- ployees at the Naugatuck Chem- ical plants in Connecticut, have participated in the cardiopulmonary resuscitation and mouth-to-mouth training.”

The overwhelming response of employees to the three courses sponsored by the Safety depart- ment is one of the highest among our Company plants.

Local 218

Talks Start

Negotiations between United Chemical Workers, Local 218 and the Company’s Industrial Relations management began on Wednesday, October 10. The purpose of the sessions is to negotiate a local supplemental agreement which will supplement the 3 year master agreement signed on June 11, 1973 in Dayton, Ohio.

Heading the Local 218 union com- mittee will be Jesse Crim, Exe- cutive Vice-President of the Local. Jesse Grim, Manager of Industrial Re- lations, will be in charge of the Company’s bargaining group.

The discussions are being held in the Local 218 conference room, and will continue until negotiations are concluded.

Prior Approval

For Tuition Aid

The Tuition Aid Program which encourages employees to continue their education requires that prior approval be obtained before taking any courses from a department supervisor.

Once approved the application authorizes tuition refunds for not more than 2 courses per semester.

Upon satisfactory completion of the courses, reimbursement is obtained by submitting a paid, itemized invoice from the school to the Accounting department.

The free lunch program…

The average American is familiar with the expression – “There’s no such thing as a free lunch.” Because we are so familiar with the saying, perhaps the full understanding of the thought gets lost and what we forget is the haunting impact of this saying, namely, nothing in life is free.

But though it may appear that there are free handouts, or that someone has beaten the system, in the long run and when all things are considered, everything has its price.

One of the most flagrant free lunch programs is some of the money Uncle Sam hands out in the form of welfare. However, the intelligent home owner, tax payer and average consumer knows, particularly now, that the bill for these goodies comes back to haunt us in the form of higher taxes, and increasing inflation. The truth of the matter is, there is no such thing as a free lunch. Our own job situation. Everything our Company provides for us must be paid for by somebody, somewhere. Part of it comes back when we pay more for the things we have to buy, and part of it comes back when a plant somewhere—anywhere—is shut down because it can no longer support the burden imposed upon it by today’s economic situation.

In order to maintain the comforting benefits provided, the main benefits, namely the must continue. Under our product- oriented system, the best way to generate wealth which supports these benefits is by increasing productivity. This is by far the best way to establish a standard of living.

The Company has a commitment to this end by providing the money and management to purchase and properly utilize equipment and facilities. The employees—you and I—have an obligation to properly and fully convert this equipment into products in the most efficient and reasonable manner possible. This is how we pay for our “free lunches.” If this deficit is allowed to grow unchecked, it will eventually—to borrow a British term—”buy our system.” Once this loss is permitted to continue, the only solution is to make a “forced loan” or write it off. In either case the adjustment is painful. The history of such a deficit is full of such adjustments and no intelligent man wants to live through such a period. No one wants his children to endure such hardships, either.

We all want reasonable improvements in our standard of living. We also want the improvements to be enjoyed by our children. Therefore, we must balance our benefits and their cost—somehow. But we all know where the burden ends up—right back where we are now. We must adjust to it and keep our livelihood in a good, healthy balance. We can then honestly say that the “free lunch” has been earned and paid for.

GIVE THE UNITED WAY

Don’t get a snow

Job on

snow tires

Get Uniroyal

Winterides

ADVANCE TIRE SERVICE

510 Meriden Rd.

Waterbury — 756-7205

FITZPATRICK’S, INC.

78 East Main St.

Ansonia — 735-3481

MEZZI0’S

792 West Haven Rd.

Naugatuck — 729-5988

POUST’S SERVICE STATION

144 Naugatuck Ave.

Naugatuck — 729-0433

—

## Page 003

A.B.S. 20 Years Later

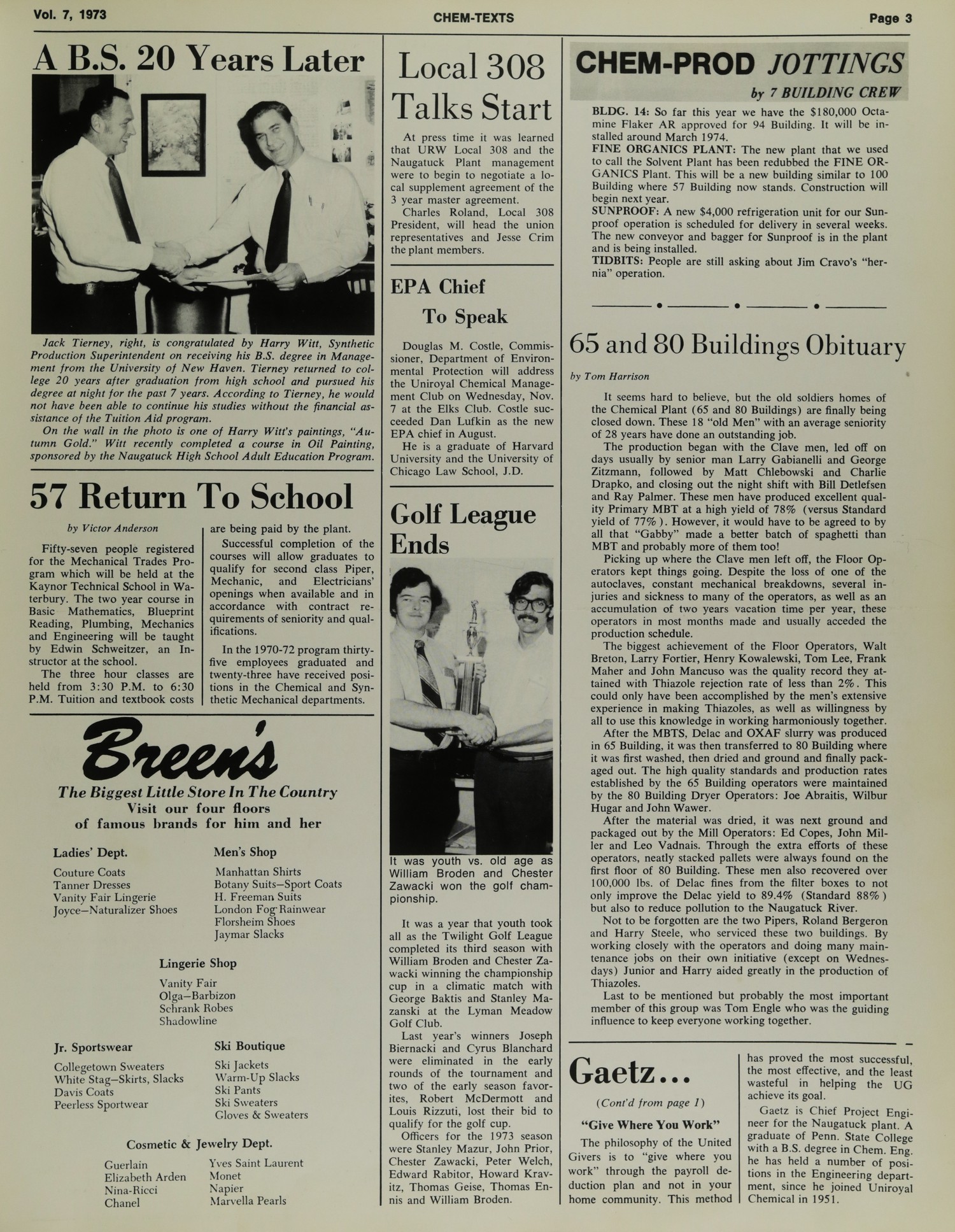

Jack Tierney, right, is congratulated by Harry Witt, Synthetic Production Superintendent on receiving his B.S. degree in Management from the University of New Haven. Tierney returned to college after graduation from high school and pursued his degree at night for the past 7 years. According to Tierney, he would not have been able to continue his studies without the financial assistance of the Union Aid program.

On the wall in the photo is one of Harry Witt’s paintings, “Autumn In New England”, which is one of the canvases donated to the Oil Painting program sponsored by the Naugatuck High School Adult Education Program.

57 Return To School

Fifty-seven people registered for the Mechanical Trades Program which will be held at the Kaynor Technical School in Waterbury. The two year course in Drafting, Plumbing, Mechanics and Engineering will be taught by Edwin Schweitzer, an Instructor at the school.

The three hour classes are held from 3:30 P.M. to 6:30 P.M. Tuition and textbook costs are being paid by plant.

Local 308 Talks Start

As we have learned that URW Local 308 and the Naugatuck Plant management were to begin to negotiate a 10-call supplemental agreement of the 3 year master agreement.

Charles Roland, Local 308 President, will head the union representatives and Jesse Crimi the plant members.

EPA Chief

To Speak

Douglas M. Costle, Commissioner of Environmental Protection will address the Univroyal Chemical Management Club on Wednesday, Nov. 7 at the Elks Club. Costle succeeded Dan Lukin as the new EPA Chief in August. He is a graduate of Harvard University and the University of Chicago Law School.

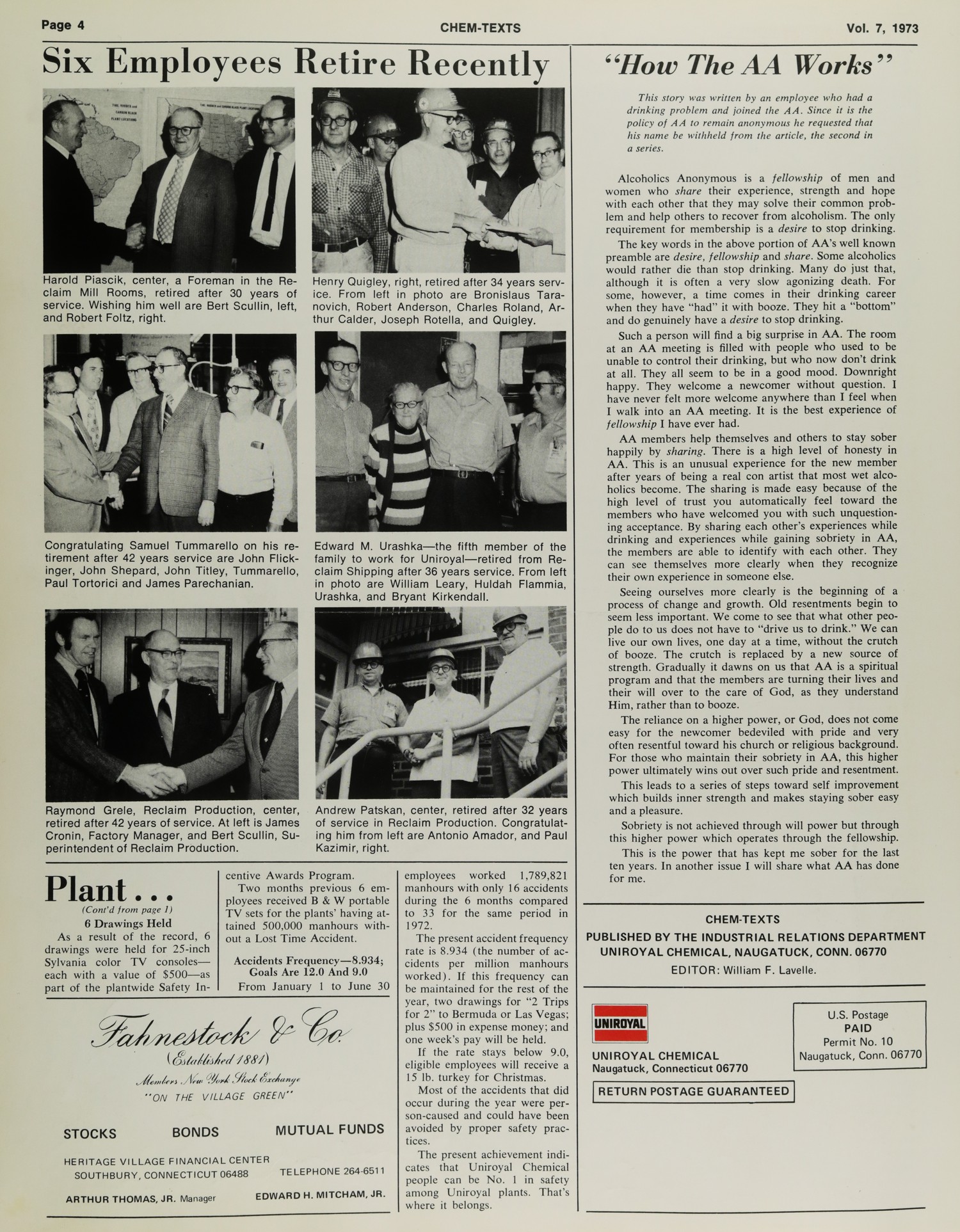

Golf League

Ends

Picking up where the Clave men left off, the Floor Operators kept things going. Despite the loss of one of the team members, constant mechanical difficulties and sickness to many of the operators, as well as an accumulation of two years seniority time per year, these operators in most months made and usually exceeded the production schedule.

The biggest achievement of the Floor Operators, Walt Barton, Larry Fortier, Henry Kowalejesk, Tom Lee, Frank Maher and John Mascaro was the quality record they attained with Thiazole rejection rate of less than 2%. This could only have been accomplished with experience in making Thiazoles, as well as willingness by all to use this knowledge in working harmoniously together.

After the MBTS, Delac and OXAF slurry was produced in 65 Building, it was then transferred to 80 Building where it was first washed, then dried and ground and finally packaged out. The high quality standards and production rates established by the 65 Building operators were maintained by the 80 Building Dryer Operators: Joe Czarnecki, Walter Hujar and John Waymire.

After the material was dried, it was next ground and packaged out by the Mill Operators: Ed Cregan, John Millier and Leo Vadnais. Through the extra efforts of these operators, neatly stacked pallets were always found on the first floor of 80 Building. These men also recovered over 100,000 lbs. of Delac fines from the filter boxes to not only improve the Delac yield to 89.4% (Standard 85%) but also to reduce pollution to the Naugatuck River.

Not to be forgotten are the two Pipers, Roland Bergeron and Harry Steele, who serviced the four log houses. By working closely with the operators and doing many maintenance jobs on their own initiative (except on Wednesdays) Junior and Harry aided greatly in the production of Thiazoles.

Last to be mentioned but probably the most important member of this group was Tom Egle who was the guiding influence to keep everyone working together.

CHEM-PROD JOTTINGS

by 7 BUILDING CREW

BLDG. 14: So far this year we have the $180,000 Octamine Fisher-AR approval for ’74 Building. It will be installed March 1974.

FINE ORGANICS PLANT: The new plant that we call the Solvent Plant has been rebubbed the FINE ORGANICS PLANT. This will be a new building similar to 100 Building where 57 Building now stands. Construction will begin next year.

SUNPROOF: A new $4,000 refrigeration unit for our Sunproof operation is scheduled for delivery in several weeks. The new conveyor and hopper for Sunproof is in the plant.

TIDBITS: People are still asking about Jim Cravo’s “hernia” operation.

65 and 80 Buildings Obituary

by Tom Harrison

It seems hard to believe, but the old soldiers homes of the Chemical Plant (65 and 80 Buildings) are finally being closed down. These 15 “old Men” with an average seniority of 25 years have done an outstanding job.

The production began with the Clave men, led off on days usually by senior man Larry Giannelli and George Drapko, and closing out the night shift with Bill Delesden and Ray Palmer. These men have produced excellent quality by Primary MBT at a high yield of 78% (versus Standard of 77%). However, it would have to be agreed to that “Gabby” made a better batch of spaghetti than Bill and probably more of them too!

Picking up where the Clave men left off, the Floor Operators kept things going. Despite the loss of one of the team members, constant mechanical difficulties and sickness to many of the operators, as well as an accumulation of two years seniority time per year, these operators in most months made and usually exceeded the production schedule.

The biggest achievement of the Floor Operators, Walt Barton, Larry Fortier, Henry Kowalejesk, Tom Lee, Frank Maher and John Mascaro was the quality record they attained with Thiazole rejection rate of less than 2%. This could only have been accomplished with experience in making Thiazoles, as well as willingness by all to use this knowledge in working harmoniously together.

After the MBTS, Delac and OXAF slurry was produced in 65 Building, it was then transferred to 80 Building where it was first washed, then dried and ground and finally packaged out. The high quality standards and production rates established by the 65 Building operators were maintained by the 80 Building Dryer Operators: Joe Czarnecki, Walter Hujar and John Waymire.

After the material was dried, it was next ground and packaged out by the Mill Operators: Ed Cregan, John Millier and Leo Vadnais. Through the extra efforts of these operators, neatly stacked pallets were always found on the first floor of 80 Building. These men also recovered over 100,000 lbs. of Delac fines from the filter boxes to not only improve the Delac yield to 89.4% (Standard 85%) but also to reduce pollution to the Naugatuck River.

Not to be forgotten are the two Pipers, Roland Bergeron and Harry Steele, who serviced the four log houses. By working closely with the operators and doing many maintenance jobs on their own initiative (except on Wednesdays) Junior and Harry aided greatly in the production of Thiazoles.

Last to be mentioned but probably the most important member of this group was Tom Egle who was the guiding influence to keep everyone working together.

Gaetz…

(Cont’d from page 1)

“Give Where You Work”

The philosophy of the United Fund Gives is to “give where you work through the payroll deduction plan and not in your home community. This method provides an additional opportunity and flexibility for charitable giving to meet the needs of the local community.

Gaetz is Chief Project Engineer for the Naugatuck Plant, a graduate of Penn. State College with a B.S. degree in Chem. Eng. He has held a number of supervisory positions in the Engineering department since he joined Uniroyal Chemical in 1964.

—

## Page 004

Here is the text extracted from the image:

Six Employees Retire Recently

Harold Piasick, center, a Foreman in the Reclaim Mill Booms, retired after 30 years of service. Wishing him well are Bert Scullin, left, and Robert Folta, right.

Henry Quigley, right, retired after 34 years service. From left in photo are Bronislaw Tarasovich, Robert Anderson, Charles Roland, Arthur Calder, Joseph Rovella, and Quigley.

Congratulating Samuel Tummarello on his retirement after 42 years service are John Flickinger, John Shepard, John Tiley, Tummarello, Paul Tedford and James Parochnian.

Raymond Grele, Reclaim Production, center, retired after 42 years of service. A life-time gift from his friends and co-workers to the superintendent of Reclaim Production.

Andrew Patskan, center, retired after 32 years of service in Reclaim Production. Congratulating him are Anthony Amador, and Paul Kaimir, right.

Plant…

As a result of the record, 6 drawings safety drawings were being distributed to 5,000—35 part of the plant wide Safety In-

Fahnestock & Co.

“ON THE VILLAGE GREEN”

STOCKS BONDS MUTUAL FUNDS

HERITAGE VILLAGE FINANCIAL CENTER

SOUTHBURY, CONNECTICUT 06488

ARTHUR THOMAS, JR. Manager

“How The AA Works”

This story was written by an employee who had a

drinking problem and joined the A.A. Since it is the

policy of A.A. to remain anonymous, he requested that

his name be withheld from the article, the second in

a series.

Alcoholics Anonymous is a fellowship of men and

women who share their experience, strength and hope

with each other that they may solve their common prob-

lem and help others to recover from alcoholism. The only

requirement for membership is a desire to stop drinking.

The key words in the above portion of AA’s well known

preamble are desire, fellowship and share. Some alcoholics

would rather die than stop drinking. Many do, in fact,

although it is often a very slow agonizing death. For

some, however, a time comes in their drinking career

when they have “had it” with booze. They hit a “bottom”

and do genuinely have a desire to stop drinking.

Such a person will find to his surprise in AA, the room

at an AA meeting is filled with people who used to be

in the same trap that he finds himself in, and have

come out of it. All will seem to be in a good mood. Downright

happy. They welcome a newcomer without question. I

have never felt more welcome anywhere than I feel when

I walk into an AA meeting. It is the best experience of

fellowship I have ever had.

AA members help themselves and others to stay sober

happily by sharing. There is a high level of honesty in

AA. This is an unusual experience for the new member

after years of being a real con artist that most alcoholics

have become. The sharing is made easy because of the

high level of trust won automatically by the seasoned

members who have welcomed you with such unquestioning

kindness. By sharing each other’s experiences while

drinking and experiences while gaining sobriety in AA,

the members are able to identify with each other. They

can see themselves more clearly when they recognize

their own experience in someone else.

Seeing ourselves more clearly is the beginning of a

process of change and growth. Old resentments begin to

seem less important. We come to see that what peo-

ple do to us does not have to “drive us to drink.” We can

live our own lives, one day at a time, without the crutch

of booze. The church is replaced by a “Higher Power, or

God” as we individually it dawns on us. AA is a spiritual

program and that the members are turning their lives and

their will over to the care of God, as they understand

Him, rather than to booze.

The reliance on a higher power, or God, does not come

easy for the newcomer bedeviled with pride and very

often resentful toward his church or religious background.

For those who maintain their sobriety in AA, this higher

power ultimately wins out over such pride and resentment.

This leads to a series of steps toward self improvement

which builds inner strength and makes staying sober easy

and a pleasure.

Sobriety is not achieved through will power but through

this higher power which operates through the fellowship.

This is the power that has kept me sober for the last

ten years. In another issue I will share what AA has done

for me.

CHEM-TEXTS

PUBLISHED BY THE INDUSTRIAL RELATIONS DEPARTMENT

UNIROYAL CHEMICAL, NAUGATUCK, CONN. 06770

EDITOR: William F. Lavelle.

U.S. Postage

PAID

Permit No. 10

Naugatuck, Conn. 06770

UNIROYAL CHEMICAL

RETURN POSTAGE GUARANTEED

NAUGATUCK, CONNECTICUT 06770

—

## Page 006

36 Get 25 Year Service Awards

In a presentation held in the office of Jim Cronin, Factory Manager, thirty-six employees were honored for their long careers with Uniroyal Chemical. Eleven of the group were made members of the Twenty Five Years Service Club, while five others were advanced to the Forty Year, Thirty-Five Year, and Thirty Year groups.

During the past year 157 employees from the plant’s manufacturing operations joined the Twenty Five Club as new members, bringing the club’s total number to 694 – roughly one-half of the people at the Naugatuck location.

One of the three women new members to join the club, Mildred Fiegel, is congratulated by Jim Cronin. From left are Frank Simmons, Americo Marques, Florian Tranovitch, William Lamon, Nicholas Buka, M.J. Fiegel, Michael Patrick, Ralph Pilato, Anthony Blake, and Earl Boone.

Receiving awards from Jim Cronin are from left: James Mask, Eugene St. John, Raymond Frank, Kenith Snyder, Victor Adamski, Laurentino M. St. Croix, Addie Hillyer, James Brown, William Maguire and Frank Chodo.

Alcoholism

Third Fatal

Illness

Alcoholism is today one of the most disastrous illnesses in America. In fatality, it ranks as Number 3, right after heart failure and cancer.

In terms of human misery it easily ranks as Number 1. The illness brings agony and suffering not only to the patient himself but to all who share his life, whether in family, in work, or in the community in which he lives.

Dreadful as unrestricted alcoholism is, Alcoholics Anonymous is today the most effective treatment of it. In future issues of CHEM-TEXTS the success of this in the treatment of alcoholism will be discussed.

Less Dimples

More Flight

By reducing the number of dimples from 336 to 252 and arranging them in a special pattern, Uniroyal has been able to improve the lift and trajectory of its latest high energy rubber center golf ball.

The new dimpled golf ball – 252 – just introduced to golf players – also breaks with the past because of its Surlyn cover which replaces the standard balata cover and increases the ball’s durability.

Fahnestock & Co

Established (1891)

MEMBER NEW YORK STOCK EXCHANGE

“ON THE VILLAGE GREEN”

STOCKS BONDS MUTUAL FUNDS

HERITAGE VILLAGE FINANCIAL CENTER

SOUTHBURY, CONNECTICUT 06488 TELEPHONE 264-6511

ARTHUR THOMAS, JR. Manager EDWARD H. MITCHAM, JR.

JA Sets Up

(Cont’d from page 1)

program is to give high school students actual experience and to develop an understanding of the basic concepts of business operations.

Each officer has a specific accountability for the success of the company’s operation. Most of them have had little business training prior to the formation of the company, but experience has proved an able teacher, and they can build a business from scratch and run it successfully.

Uniroyal Chemical Advisors to the company are Randolph Porter, Michael True, Cheryl McMahon, Thomas Reynolds and Thomas Schmidt.

Tire Plant To

Triple Radial

Production

Uniroyal announced the start of production of steel belted radial tires at the Opelika, Ala. plant as part of an overall conversion program that will triple the current production rates for this new tire type by the end of 1973.

In addition to the Opelika plant, the Company produces radial tires at its plants in Detroit and in Ardmore, Okla., which is the only plant in the U.S. designed specifically for this type of tire.

With the completion of the Opelika program, Uniroyal will have invested more than $100 million in this type of tire in the U.S.

The Company has produced more steel belted radials, worldwide, than any other American tire manufacturer.

By 1977, more than 80% of the nation’s new cars and more than one-half of all replacement tires sold, will be steel belted radial ply construction.

First Treasurer Retires

William Adamski, center, Synthetic Mechanical, receives a gift from Rocco Marulla, Vice President, URW Local 308 Vice President, on his retirement after 40 years of service. Other union officers in the photo are, from left: Adamski; Arthur Calder, secretary; and Manilla. Adamski was the first treasurer of the Local 308.

BOB’S CAMERA SHOP INC.

21 Grand Street, Waterbury, Conn. 06702 754-2256

Films • Cameras • Projectors • Developing & Rentals

CHEM-TEXTS

PUBLISHED BY THE INDUSTRIAL RELATIONS DEPARTMENT

UNIROYAL CHEMICAL, NAUGATUCK, CONN. 06770

EDITOR: William F. Lavelle.

UNIROYAL

CHEMICAL

NAUGATUCK, CONNECTICUT 06770

RETURN POSTAGE GUARANTEED

U.S. Postage

PAID

Permit No. 10

Naugatuck, Conn. 06770

Letters To

The Plant

Dear Mr. Shaw:

On behalf of our Social Action

Committee and everyone of our

people who attended the tour of

your pollution control facilities on

Sunday, I offer thanks to everyone

concerned. We had an excellent

guide, ready with both questions

and answers.

In this day so obviously concerned with pollution control, both

my opinion and that of our Social

Action Committee that too often

are easily condemn those who do

nothing and we ourselves often

fail to do something. On Sunday at

least we had an opportunity to

praise and not condemn and, indeed, Uniroyal does deserve appreciation for its efforts to

become our environment’s guardian.

Again, thank you for the

“above and beyond” effort to inform and educate our group.

Sincerely yours,

Rev. Albert F. Garcia

—