## Page 002

Here is the text extracted from the document image, preserving the layout and structure as much as possible:

Page 2 CHEM-TEXTS Vol. 11, 1977

Reward for Working Safe . . . Reclaim Plant Dismantled

For the past few weeks our bul-

letin boards have had notices ex-

plaining our 1977 Safety Goals

and announcing a Safety Contest

that will be operating during

1977. The Safety Contest is being

run really to help you remember

to work safe!

Why are we willing to reward

you for working safely? In almost

every instance, after an accident

has occurred, an investigation

finds that it was caused by hat-

tention. All of us have to remem-

ber, every day, that we are work-

ing in conditions that can be ex-

tremely dangerous. The Company

can, and does invest millions of

dollars to assure the safety of its

employees, but all of it goes to waste, if during the working day, we’re

careless. Little things like wearing hard hats, safety glasses or taking

the extra time to get a face shield, or gloves when necessary, making

sure that the line is empty before doing any major maintenance on

things, and insuring that all electrical equipment is “locked out” properly. Some of these

things will cause you to walk a few extra steps and perhaps “slow down” sometime, but if it prevents an accident it is well worth it.

If it is a time-worn but true phrase: “ONLY YOU CAN PREVENT

ACCIDENTS.”

During ’76 as all make sure you concentrate on safety every

hour of the day and also be a good neighbor–if you see someone

working next to you unsafely, remind them so that they can be there

again tomorrow.

If we all do these little things I am sure we’ll reach our 1977 goal

and you can have your Christmas dinner on us!

Waste Saves Over $16,000

A crane loads a scrap reactor into a trailer truck. The scrap metal

program has not only improved housekeeping but has netted $16,000

in savings.

By Peter Thomas

A scrap metal salvage program

was started in early 1975 with the

Schuyler Company to buy and

salvage the scrap throughout the

plant. Schuyver furnished the

truck and the boxes for the small

loose scrap and then they picked

up the material spots in the yards

and the larger items were placed

in a pile. After the scrap items

were placed in the boxes or

trucks, the 55 gallon drums

were placed in the buildings

throughout the plant for smaller

pieces. When filled, they were

taken to a collection point.

Up to the present time it costs

more than $3.00 per short ton to

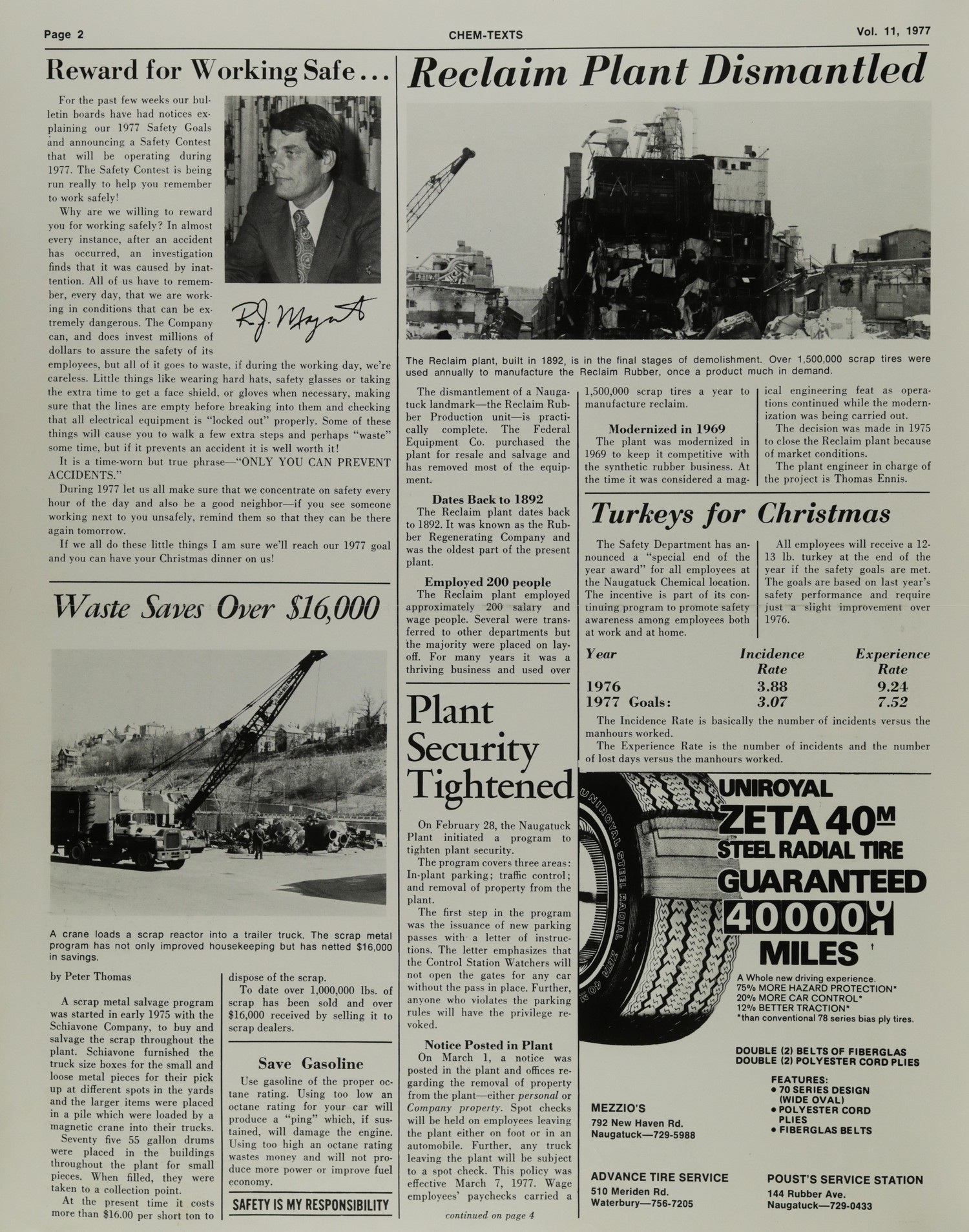

The Reclaim plant, built in 1892, is in the final stages of dismantlement. Over 1,500,000 scrap tires were

used annually to manufacture the Reclaim Rubber, once a product much in demand.

The dismantlement of a Nauga-

tuck, Connecticut – the Reclaim Rub-

ber Plant – was virtually and physi-

cally complete. The Federal

Equipment Co. purchased the

plant for resale and salvage and

has removed most of the equip-

ment.

Dates Back to 1892

The Reclaim plant dates back

to 1892. It was known as the Rub-

ber Regenerating Company and

was the oldest part of the present

plant.

Employed 200 people

The Reclaim plant employed

approximately 200 salary and

wage people. Several were trans-

ferred to other departments but

the majority were placed on lay-

off. For many years it was a

thriving business and used over

1,500,000 scrap tires a year to

manufacture reclaim.

“Modernized” in 1969

The plant was modernized in

1969 to keep it competitive with

the synthetic rubber business. At

that time it was considered a ma-

jor engineering feat as opera-

tions continued while the moderni-

zation program was underway.

The decision was made in 1975

to close the Reclaim plant because

of market conditions.

The plant engineer in charge of

the project is Thomas Ennis.

Turkeys for Christmas

The Safety Department has an-

nounced a “special end of the

year award” for all employees at

the Naugatuck Chemical location.

The incentive is part of its con-

tinuing program to promote safety

awareness among employees both

at work and at home.

Year Incidence Experience

Rate Rate

1976 3.88 0.21

1977 Goals: 3.07 7.52

The Incidence Rate is basically the number of incidents versus the

manhours worked.

The Experience Rate is the number of incidents and the number

of lost days versus the manhours worked.

UNIROYAL

ZETA 40M

STEEL RADIAL TIRE

GUARANTEED

40000

MILES

FEATURES:

– WIDE OVAL DESIGN

– POLYESTER CORD

PLIES

– FIBERGLASS BELTS

MEZZ|O’S

792 New Haven Rd.

Naugatuck—729-5988

ADVANCE TIRE SERVICE

310 Meridian St.

Waterbury—756-7205

POUST’S SERVICE STATION

144 Baldwin Ave.

Naugatuck—729-0433

Save Gasoline

Use gasoline of the proper oc-

tane rating. Using too low an

octane rating for your car can

produce a “ping” which, if sus-

tained, will damage the engine.

Using too high an octane rating

wastes money and will not pro-

duce more power or improve fuel

economy.

SAFETY IS MY RESPONSIBILITY

(continued on page 4)

All employees will receive a 12-

lb. turkey at the end of the

year if the safety goals are met.

The goals are based on last year’s

safety performance and require

just a slight improvement over

1976.

Plant

Security

Tightened

On February 28, the Naugatuck

Plant initiated a program to

tighten plant security.

The program covers three areas:

In-plant parking: traffic control;

and removal of property from the

plant.

The first step in the program

was the issuance of new parking

passes with a letter of instruc-

tions. The letter emphasizes that

the Control Station Watchers will

check passes as employees enter

and leave the plant. Anyone

without the pass in place. Further,

anyone who violates the parking

rules will have the privilege re-

voked.

Notice Posted in Plant

On March 1, a notice was

posted in the plant and offices re-

garding the removal of property

from the plant—either personal or

Company property. Spot checks

will be held on employees leaving

the plant either on foot or in an

automobile. Further, a new policy

has been established and will

take effect March 1, 1977. Wage

employees’ parcels carried a

—

## Page 004

Page 4 CHEM-TEXTS Vol. 11, 1977

Three Retire… Salzman… Thiazoles Unit Torn Down

Dominic Camo, center, retired from the Materials as a member of the Synthetic Rubber plant’s Con-

department after 34 years of service. From left are trol Laboratory after graduation from Pratt Insti-

W. Bryan Kirtendall, Camo and Thomas Carry. tute in Brooklyn, N.Y.

In 1960 he was named a Sr. Engineer in the In-

dustrial Engineering department and was transferred

to the Painesville, Ohio plant.

Returns to Naugatuck

Victor Adamski, center, retired after 35 years serv- In 1961 he was named Chief Process Engineer and

ice. From left are Anthony Curall, Beldon Antrim, Chemical Production and in 1965 became Manager

Robert Fofe, Adamski, Louis Morel, John DeSantis, of Engineering. He later became Plant Engineer and

and Robert Breton. Materials Flow Manager in 1969. From 1972 to 1975 he

was Director of European Chemical Operations.

Upon his return to the U.S. in 1975 he was named

General Manager of Chemicals and Polymers.

Sales…

Leisure, Sport and Other

Leisure, Sport and Other sales totaled $80 million

Increases occurred in Naugatuck’s coated fabrics, compared to $41 million in 1975. These Leisure

Ensolite®, hose, and storage tanks. Industrial Prod- sales totaled $18 million or 16% of the Company’s

ucts sales were 15% of Company sales. sales as compared to $22 million in the previous

year.

Hospital…

and pulmonary function room, audio/visual room

and a cliical and hydrotherapy room. New light-

ing, heating and air conditioning will also be in-

stalled.

A Central Location

Several locations have been studied as sites for the

expansion. Bldg. 75 offered the best location, being

in the geographical center of the plant for the most

people.

It is estimated that completion of the project will

be 12 months after the initial work begins.

Layout and investigatory work is presently being

done by the Engineering Department in conjunction

with the Medical and Safety Departments.

Flanary

continuing from page 1

to be responsible for Corporate Research; Develop-

ment and Planning; and the Plantations, Chemical

and Textile Divisions.

He joined the company as a Research Chemist in 1959, after graduation from the

Lowell Technological Institute and the Harvard

Graduate School of Business.

He held a number of management positions in

Sales and Marketing and was named President of

the Chemical Division in 1975. He will be located

in Oxford.

The three top executives in the company – David

Berea, Andrew McNeill and Joseph Planner – are

Uniroyal Chemical people who started their careers

at the Naugatuck Chemical plant.

Club…

Daniel Shatto.

The winner of the 1976 scholar-

ship was Mary Alice Schmeckel,

the daughter of William Schmeckel,

of Research and Development in

TSCC.

Safety is My

Responsibility

Bldg. 65, an old steel framed corrugated building,

located behind Bldg. 30, has been totally removed

by a New Haven Wrecking Co. The building, which

was constructed in 1935, was used to manufacture

the Thiazoles. When the market demand for the

Thiazoles exceeded the production capacity of

the unit, the product was moved to the division’s

newer chemical complex in Geismar, La.

25 Year Club…

30 YEARS SERVICE: Sheldon

Shuman congratulates Harold

Boyce, Research Chemist/Engi-

neer, for his 30 Years service with

the division.

Alexander Nole, right, Materials

Flow Manager, is congratulated by

Dominic Camo, retired Materials

Flow Manager, upon the comple-

tion of 35 years of service.

BOB’S CAMERA SHOP INC.

WATERBURY’S LEADING CAMERA SHOP

80 South Main St., Waterbury, Conn. 06702 754-2256

Fine • Camera • Projectors • Developing & Rentals

CHEM-TEXTS

PUBLISHED BY THE INDUSTRIAL RELATIONS DEPARTMENT

UNIROYAL CHEMICAL, NAUGATUCK, CONN. 06770

Equal Opportunity Employer

EDITOR: William F. Lavelle.

U.S. Postage

PAID

Permit No. 10

Naugatuck, Conn. 06770

UNIROYAL CHEMICAL

Naugatuck, Connecticut 06770

RETURN POSTAGE GUARANTEED

Chittenden

Insurance Agency, Inc.

Insurance-Mutual Funds-Real Estate

180 Church Street

Naugatuck, Connecticut

Tel. 729-8209

Frederick D. Zonino Nathan M. Pierpont, Jr.

—