## Page 001

CHEM-TEXTS

Vol. 2 PUBLISHED FOR THE PEOPLE OF UNIROYAL CHEMICAL No. 2.

New Equipment for Reclaim Plant Will

Keep Us in Reclaim Rubber Business

Our present reclaimed

rubber plant dates back to

1895, after fire destroyed the

original plant in 1893. For 75

years, we have played an im-

portant role in the rubber

industry by supplying high

quality stocks.

Several years ago, with

combining higher production

costs and increased shipping

expenses, profitability reached

a critical point. As a result, our

reclaimed rubber business,

Peace with keen competition,

reduced prices and low-cost

new rubber as an alternate,

our business was placed in a

difficult position. A decision

had to be made either to dis-

continue the business or make

major capital investments to

modernize the facilities.

After detailed study of the

present operation and various

improvements and consider-

ing the skills of our people,

it was decided that a modern-

ization of the facilities would

be practical and increase our

ability to successfully compete

in the market place. An ap-

propriation request for these

plans was drawn up and

approved.

The “new” plant, effi-

ciently and effectively oper-

ated, will protect the job se-

curity of 150 employees while

at the same time, assure the

future of the business.

Changes in the dimensions,

reduced from 3 to 1, will affect the

roles of about 50 employees.

A project team was form-

ed to work on the problem.

The team settled on 5 major

changes which would offer the

best return on investment at

this time: 1. fibre separation;

2. fine grinding; 3. central

mix in the mill room; 4. revis-

ion in the mill room; 5. tenth

and dyer revisions.

The team in charge of the

project, including closed belt

of the New York engineering

group were R. Gass, Engi-

neering Dept., Ted Lemna,

Reclaim Development, C.

Reich, Production and F.

Wintsch, Industrial Engineer-

ing. Since this transfer to In-

dustrial Relations, Wintsch

has been replaced by B. Daly.

This team was charged

with the responsibility of

making the project go: by

developing the flow sheets

and recommending the type

of equipment. All the details

of engineering is being hand-

led by approximately 12 mem-

bers of the New York corpo-

rate engineering staff.

The job to be done con-

sists of removing the fibers

from old tires to prepare them

for the fine grinding opera-

tion. By doing a better job

of removing the fibre in the

early steps and also by finer

grinding, the disaster cycle

will be shortened, and chemi-

cal costs reduced. Also, the

grinding prior to digesting,

allows us to make one pass

through the mill rooms instead

of 4 passes under the old sys-

tem. The fine grinding,

fibre separation and central

mixing will be new depart-

ments and will require new

skills. Engineering also es-

timates that we would have

U.S. BOND DRIVE AIMS

FOR 50% PARTICIPATION

John D. Evans, Factory

Manager, named Fred Win-

tsch chairman of the 1968 U.S.

Savings Bonds and Freedom

Shares Drive at the Nauga-

tuck plant. The drive was

sponsored for two weeks from

May 6 to May 17.

Last year’s campaign at

the Naugatuck plant added

72 new savers to the payroll

deduction plan; 388 employees

increased their participation:

and 152 purchased the new

Freedom Shares. Approxi-

mately 40% of the Chemical

employees were enrolled in the

U.S. Savings Bonds and

Bonds and Freedom Shares.

The goal for the 1968

drive, according to Wintsch

was again 50% participation

by Chemical employees. The

drive committee members had

been organized in different

sections of the plant.

Members of the committee

were the following: Warren

Singleton, E. G. Broderick,

Mary Sullivan, J. Flickinger,

Harold Smith, L. Anderson,

S.E. Salva, R.W. Knutzman, L.

P. Ferringo, T.J. Shillinkas,

Harold Campbell, O. Zapra-

zaka, R.M. Bioski, M.A.

Lusky, D. Johnson, E. J.

Greene, F.X. O’Shea, R. Ro-

senbum, C.C. Smith, A.

Budd, J.A. Prager, P.J. Le-

zarus, W.R. Smith, V.R. Led-

dell, A.J. Loman, J.F. Zappala,

M.E. Kerryn, G.M. Stone,

M. Juliano, D. Pagano, C.

Terrinella, L. Ghettie, B.

Dodd, T. Dowling, J. Hoyup-

ski, F. Magnano, L. Cozza,

G. Bakis, W. Frankenberger,

A. Emanuil, A. Piastrak,

E. Polonis, W. Booth, D.

Rappofe, T. Skleton, H. Fink,

C.R.R. Foltz, M. Mazur,

S. Perks, B. Magnano, J.

McMahon, L. Opdyke, L.

Evans, J. Casey, L. Capello,

B. Rice, J. Tripp, F.

Landon, D. Nelson, J. Mur-

tha, J. Rentier, R. Burns,

J. Quinn, V. Alves, J. Carroll,

R. Fenton, J. Kaminski, P.

Noland, R. Krajewski, P.

George Murdock of the

Treasury Department advised

the group on the advantages of payroll deductions as an important part of an em-ployee’s savings program. 70% of Savings Bonds purchasers do not redeem them until after

age 65. In this way, the tax

liability on E Bond interest could be greatly reduced and even eliminated entirely under some circumstances.

Foremen’s Club Elects Officers

The Naugatuck Chemical

Foremen’s Club elected Lou

Kaiser president of the Club

at its monthly meeting at the

Elks’ Club. Other officers

named were Joe Bucciaglia,

Vice-President; Ian Baclawski, Secretary and Joe Murtha, reelected as Treasurer.

They succeeded Vic Alves,

Earl Wright and Eric Johnson

who served as the Club’s

officers the past year.

The Club held its annual

banquet on May 16 and will

hold a dinner dance in Octo-

ber; outdoor summer picnics

and a summer picnic for

the family.

A membership drive is

being organized to increase

the Club’s members. Any sala-

ried, male employee of the

Naugatuck plant can join the

Club which sponsored a $250

scholarship fund this year.

Still in the idea stage,

Kaiser hopes to organize dis-

cussion meetings between

representatives of various

departments to interchange

ideas and to become better

acquainted with and under-

stand the problems of different

departments. By open table

discussion, production, engi-

neering, R & D, materials

handling, maintenance and

other departments would get to know each other’s problems

more easily and inte-

grate their activities more effectively.

(Continued on Page 2)

—

## Page 002

FROM THE FACTORY MANAGER

Dear fellow employee:

When we were children it seemed like an eternity waiting

for Christmas to arrive with its many joys. Now, too often, we

find Christmas upon us too soon to appreciate its many meanings to all of us. We complain when Christmas decorations

start to appear before Thanksgiving that Christmas is becoming

too commercial. But possibly in our complex and “perniciously

busy” society we need the extra lead time.

Yes the advertising: to set our minds for

the approach of Christmas.

Who, but the most bitter “Scrooge”

will for one moment deny the warm glow

of fellowship with family and friends

that descends upon all of us as the spirit

of Christmas comes into our lives. Yet,

the very hope and promise of Christmas

too frequently comes as a false spring

day in February only to be followed by

a return to the dreariness of winter. Perhaps we aren’t too

old not to continue to wish that Christmas could last the

year around?

This, then, is my Christmas Wish for you and your family;

a wish for all the good things of life and a hope for a New Year

with its full measure of health and happiness.

John Lawton Wins Top Suggestion Award

John Lawton of the $15.00: Joe Gallucci, Mechanical, $25.00; Fred Surmann,

Synthetic Processing department was awarded $100.00 during Processing, $15.00; Charles

a recent meeting of the award Harris, Laboratory. Honorable

committee at the Synthetic Mention: Frank Phillips,

Plant. John’s idea to install Chem. Mix, Honorable Menaddition sensor valves on the tion: Leon Raskataska, Profront lines of certain reactors cessing, Honorable Mention:

resulting in productivity savings Dan Donato, Mechanical,

and elimination of some con- $15.00; Earle Root, Processing,

tamination. During the meet- $30.00; Earle Root, Processing,

ing a total of 16 awards were $15.00; Alan Happy, Processsmade — 9 cash awards totaling ing, Honorable Mention;

$250 and 7 honorable mention. Alan Happy, Processing,

Other winners were: Fred Honorable Mention and Frank

Surmann and Robert Lock- Phillips, Chem. Mix, $20.00.

wood, Processing, Honorable Note: This does not include

Mention: Joe Wojczak, Pro- Chemical and Reclaim plants.

cessing, Honorable Mention: Meetings incomplete at press

Charles Harris, Laboratory. time.

Did You Know?

… That our society hurls

more than 130 million tons of

pollutants skyward each year

and approximately 2/3 of this

waste comes from motor

vehicles. The major causes

of pollution that make up this

total are:

Motor vehicles

85 million tons

Manufacturing

22 million tons

Electric Power Generation

15 million tons

Heating of buildings and homes

9 million tons

Total

130 million tons

… Research has shown that

pollution caused by exhaust

gases and crank case emissions

from automobiles may be controlled by what is called

Positive Crankcase ventilation. Positive crankcase

ventilation draws unburned

pollutants out before they

enter the exhaust system of

the car and returns them

back into the carburetor fuel

intake where they are burned

off. As a result of this there

is an estimated 30% reduction

in pollutants. The entire system was made possible through

the use of a hose connection

made of Platinum Nitride rubber

which has a high resistance to

heat and oil. Positive crankcase ventilation is now standard on all cars being manufactured in the United States.

Thus UNIROYAL CHEMICAL through its production

of Nitril rubber at our

Painesville, Baton Rouge

plants is making a major

contribution in the battle

against air pollution.

… That we have received

our order from the state to

install the water treatment

facilities in the plant by

February 1971. The first step

in the inevitable for this equipment has been complied with

when we submitted our initial

engineering report prior to

November 30, 1967.

First Aid . . . Think Ice

One of the most effective and

safe medicinal aids is an ice cube. Ice

is safe because it refrigerates, rather

than freezes, tissue.

1. To relieve pain, think about it:

Before removing a splinter with a

needle, first apply an ice cube until it looks numb.

2. If you should burn your fingers,

immediately hold them under cold

water, then into a bucket of ice and

water until the pain is gone. This will

prevent blisters. Later, you can use

an ointment.

3. For a headache, overcome with

heat, hold an ice cube in your fist.

A heat stroke can be relieved

by wrapping the body in wet towels,

arms, legs, and back.

4. To reduce and eliminate bleeding,

place ice on the cut. If it will not

control the bleeding.

5. To get rid of headaches, put an ice

cube in the mouth. Suck on it, for it

will cool the pain, relax tense muscles, and relieve the pain. Almost instant

Vol. 1 No. 3

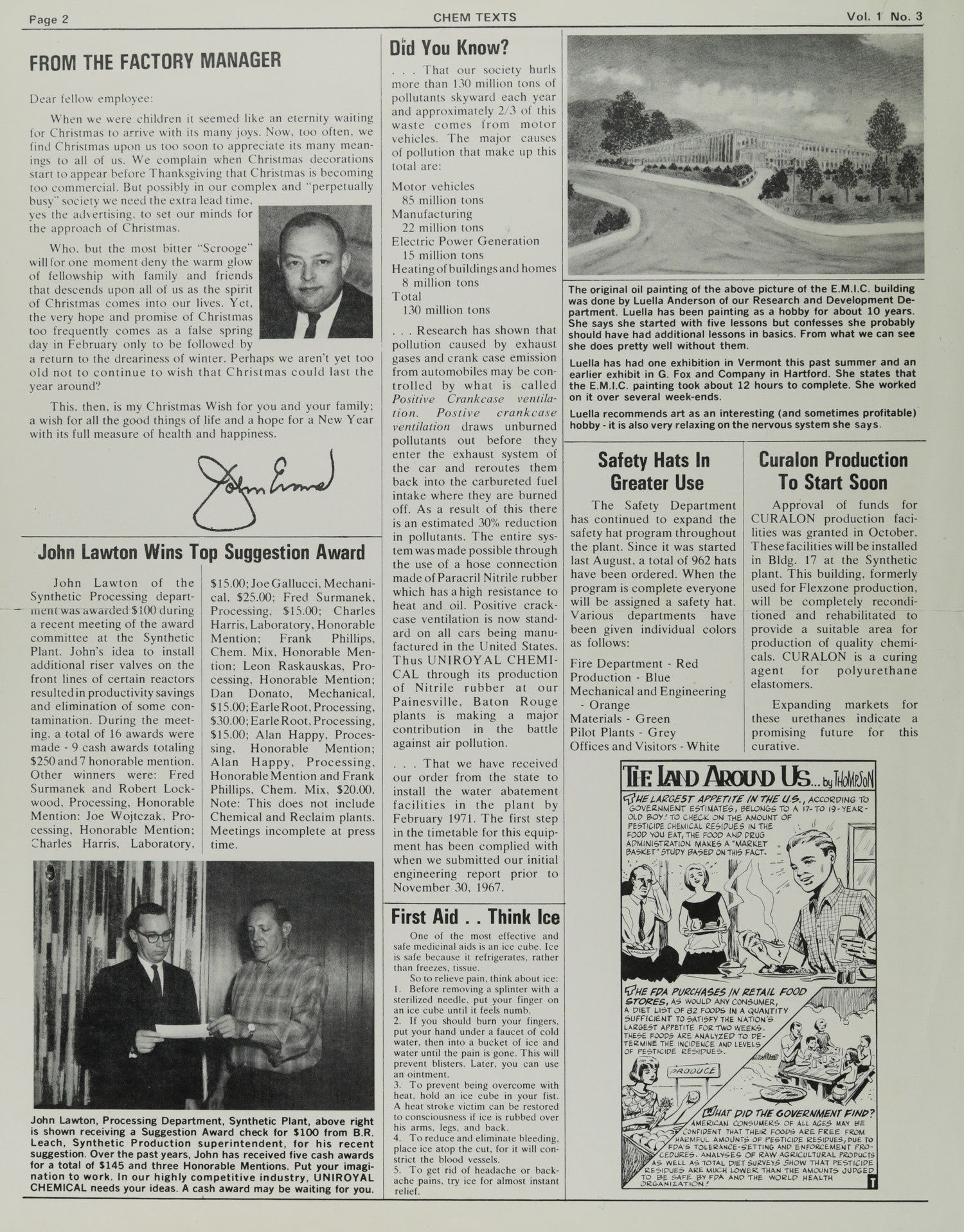

The original oil painting of the above picture of the E.M.I.C. building

was done by Louis Anderson of our Research and Development Department. Luella has been painting as a hobby for about 10 years.

She was started with five lessons but confesses she probably

should have had additional lessons in basics. From what we can see

she does pretty well without them.

Luella has had one exhibition in Vermont this last summer and an

earlier exhibit in G. Fox and Company in Hartford. She states that

since she has taken up painting she finds it very relaxing and she

plans to take in about 12 painting exhibitions during the winter months

or over several weekends.

Luella recommends art as an interesting (and sometimes profitable)

hobby: it is also very relaxing on the nervous system she says.

Safety Hats In Curalon Production

Greater Use

To Start Soon

The Safety Department

has continued to expand the

safety hat program throughout

the plant. Since it was started

last August, a total of 962 hats

have been ordered. When the

program is complete everyone

will be assigned a safety hat.

Various departments have

been given individual colors

as follows:

Fire – Production – Red

Production – Blue

Mechanical and Engineering

– Orange

Maintenance – Green

Pilot Plants – Grey

Offices and Visitors – White

Approval of funds for

CURALON Production facilities was granted in October.

These facilities will be installed

in Bldg. 7 at the Synthetic

plant. This building, formerly

used for Flexone production,

will be completely recondiefficiency and rehabitioned and remodeled to produce quaition granted to a suitable area for

production of quality chemicals. CURALON is a curing the

agent for polyurethane

plastics.

Expanding markets for

polyurethanes indicate a

promising future for this

curaline.

The Lean Around Us

TAKE

TIME NOW TO SPEND ON THE AMOUNT

YOU EAT – FROM IT THE GOVERNMENT BASES

ITS FOOD AND DRUG ADMINISTRATION’S MARKET

BASKET ON THE FACTS.

GIVE IT A CLOSER LOOK-THESE

PURCHASES IN RETAIL FOOD STORES WERE

MADE DURING THE PERIOD OF GREATEST APPETITE,

A DIET LIST OF 38 ITEMS IN A QUANTITY

SUFFICIENT TO FEED A FAMILY OF FOUR,

LARGEST APPETITE FOR TWO WEEKS.

—