## Page 002

FROM THE FACTORY MANAGER

Dear Fellow Employees:

Those of us involved in the “STOP” safety training program are repeatedly asked the question, “Who is responsible for safety in my area?” Each of us recognizes there is only one correct answer: “I am.” However, there will only be an effective safety program in our plant if every employee is responsible for his own activities.

Mr. Vila has clearly stated the UNROYAL philosophy on accident prevention. I would like to quote the following portions of this statement:

“Managers at all levels, have, as a primary responsibility, the safety and well being of all persons who report to or are assigned to them.”

“Each employee has an important place in the accident prevention effort and he must accept the responsibility for full cooperation in the measures taken for safety.”

I have underlined RESPONSIBILITY – a key factor in the jobs of all of us. Let’s all work together in a responsible manner to prevent personal injuries.

John D. Evans

LOST TIME ACCIDENTS UP IN FEBRUARY, DROP IN MARCH

Lost time accidents jumped from 2 in January to 3 in February. But dropped from 3 to 2 in March. However, the record for serious injuries jumped from 2 in January to a total of 6 in March.

For the first 3 months of the year, there were a total of 7 lost time injuries and for the same period a total of 12 serious injuries.

Severe bruises and sprains accounted mostly for the lost time accidents; while two fractures occurring, one of a finger and one wrist fracture. Oftentimes there’s a hairline difference between these accidents and more serious ones. A “stop, look and listen” attitude toward personal safety would eliminate these incidents that not only affect the employee, but his family and all of us for not wearing proper protective equipment on the job.

678 Minor Injuries Occur In January, February and March

In the first 3 months of the year, 678 minor injuries occurred, requiring visits to the plant nurses. If this rate continues for the next 9 months, approximately 2712 minor accidents will take place. The plant presently employs about 1680 people; so this rate every employee is responsible for his own activities.

TOTAL MINOR ACCIDENTS BY DEPARTMENTS FOR JANUARY, FEBRUARY AND MARCH

Chemical Production 17 13 16 0 4 8 11 5 4 3 8 90

Reclaim Production 4 10 0 42 0 2 0 8 5 0 5 4 80

Synthetic Production 0 8 0 11 0 5 0 7 1 0 4 0 37

Materials Handling 8 7 0 34 0 0 0 5 4 1 11 0 70

Mechanical (Chemical) 3 30 1 75 0 1 3 10 3 0 38 7 180

Maintenance (Syn) 18 22 0 38 0 10 4 6 4 0 14 3 104

Research & Development 3 11 2 33 0 10 9 5 3 5 7 8 101

Other 2 2 0 6 0 0 0 3 1 1 1 0 16

3 Months Total 57 93 4 255 0 40 24 55 26 11 83 30 678

New Equipment

(Continued from Page 1):

to make major replacements in our departments that we continued under the old system. For the most part, the job of installation for fibre separation and fine grinding equipment and the system is undergoing trial runs to work out the “bugs”. It is hoped that central mining and the mill room changes will be complete by the end of 1968.

Auto Belt Survey Shows Fewer Drivers Using Them

More automobiles are equipped with seat belts than ever before, but fewer people proportionately are wearing them, according to a nation-wide survey reported by the Auto Industries Highway Safety Committee in 1967.

Nearly two-thirds-65 per cent-of the more than one million cars checked were equipped with seat belts. Yet barely more than half the drivers questioned said they always use them on long trips, or 5 per cent less than a year earlier. Only 38 per cent reported they always use belts in local travel.

In 1963, before seat belts were standard equipment in all American cars, only 9 per cent of the cars surveyed were so equipped, but near-ly three out of every four drivers responding answered “always” to the use “on long trips” question. The percentage of persons stating “never wear” seat belts even on long trips increased to 17 per cent, compared with 10 per cent in 1966.

The Seventh Annual Seat Belt Installation and Use Survey was made during this year’s National Vehicle Safety Check, a voluntary community program sponsored by the Committee, in which more than 4,700 communities participated. Cars were checked and drivers interviewed in both urban and rural areas from coast to coast.

George R. Vila, chairman and president of Uniroyal, Inc., recently appointed 1968 rubber industry chairman for the U.S. Savings Bonds Campaign, chats with Mrs. Dorie Damuth, Mrs. U.S. Savings Bonds for 1968.

Vila, Chairman of U.S. Savings Bonds Drive

George R. Vila, chairman and president, Uniroyal, Inc., has been named to the Treasury Department’s U.S. Industrial Payroll Savings Committee by Secretary of the Treasury Henry H. Fowler.

Mr. Vila will serve as chairman for the rubber tire industry in the 1968 U.S. Savings Bonds Campaign. He will be responsible for planning and leading the campaign.

At Uniroyal plants, the campaign will be run during the month of May. The major promotional efforts were concentrated in the weeks of May 6th and May 13th.

At the Naugatuck plant, Fred Wintsch of Industrial Relations was in charge of the campaign to promote the Saving Bond and Freedom Share drive.

—

## Page 003

Reclaim Quality To Improve

With New Modern Equipment

Water Pollution Will Be Reduced

The following pictures to control the lint escape

show some of the latest manu- after the fibre was separated

facturing equipment the from the rubber. The new

Company has recently pur- equipment now makes it pos-

chased to keep us in business sible to catch the line lint

against strong competition. and bale it like hay. This new

Improved quality of our re- piece of equipment will now

claimed rubber will result control the amount of lint

from the finer grinder and that was formerly discharged into the Naugatuck River,

fibre separation machines. and causing a pollution pro-

Some equipment has been blem. After the moderniza-

already installed and is under- tion program is completed,

going shakedowns to work further studies will be made

out the “bugs”. The miracle and evaluated to reduce the

of the modernization of the air pollution caused by the

plant is that full scale pro- reclaim manufacturing pro-

duction is continuing without cess. This fits in with the Divi-

interruption. sion’s policy of air and wa-

Previously it was difficult ter pollution abatement in

the area.

PURDUE U. INSTALLS OUR

ALL-WEATHER “RUBBER” TRACK

“The installation of the first all- and new outdoor all-weather the runner’s

weather rubber track at Purdue has always time on Monday or Tuesday

been a major and costly ex- will be the same time as the

pense. Inasmuch as any number of advantages, rest of the meet.

we are now able to get a boy not the least of which is that The “rubber” track can be

ready for the track instead we are now able to get a boy installed in practically one

of having to delay for several ready for the track. Instead day. The installation is made

highly respected track coach of the lengthy process, highly next with regular highway

for 20 years. Dave Rankin. respected track coach for 20 paving equipment. Usually

years, Dave Rankin. two Chemical R & D person-

Sold under the tradename nel are on the spot to provide

“U.S. Royal Track”, the sur- technical assistance to the

face is a mixture of specially contractor, prior to

selected natural and synthe- installing his bid to Purdue.

tic rubber made at Nauga- made it difficult to

tuck. The rubber must be of pave, difficult to

the highest quality to produce handle, con-

a smooth uniform texture and trol and roll. The U.S. Royal

mixed with asphalt cement track won out for its reputa-

and fine aggregates at a con- tion of a quality product.

tractor’s hot mix plant.

Unlike cinders, which

are high-priced and difficult

to buy, the “rubber” track

can be used 12 months a year

under almost any weather

conditions. This new all-weath-

er track practically makes

postponements a thing of the past.

The “rubber” track doesn’t

create dust and can be painted

with long-lasting markings

that stay clean and sharp

under constant usage.

The track is tough but

pliable enough to give under

pressure without cracking.

Unlike cinder or clay tracks,

the spikes do not dig up the

track permanently, because

the rubber surface quickly

restores itself.

Maintenance of cinder

New control panel will aid all operators in controlling the operation of

fibre separation and fine grinding.

New baler equipment collects and bales int previously discharged

into Naugatuck river.

—

## Page 004

CHEM TEXTS

Page 4 Vol. 2 No. 2

Enter Safety Slogan Contest

Win $25.

SAFETY SLOGAN

Contest #2

Date:

Name

Address

Dept.

My suggestions are:

1.

2.

3.

4.

5.

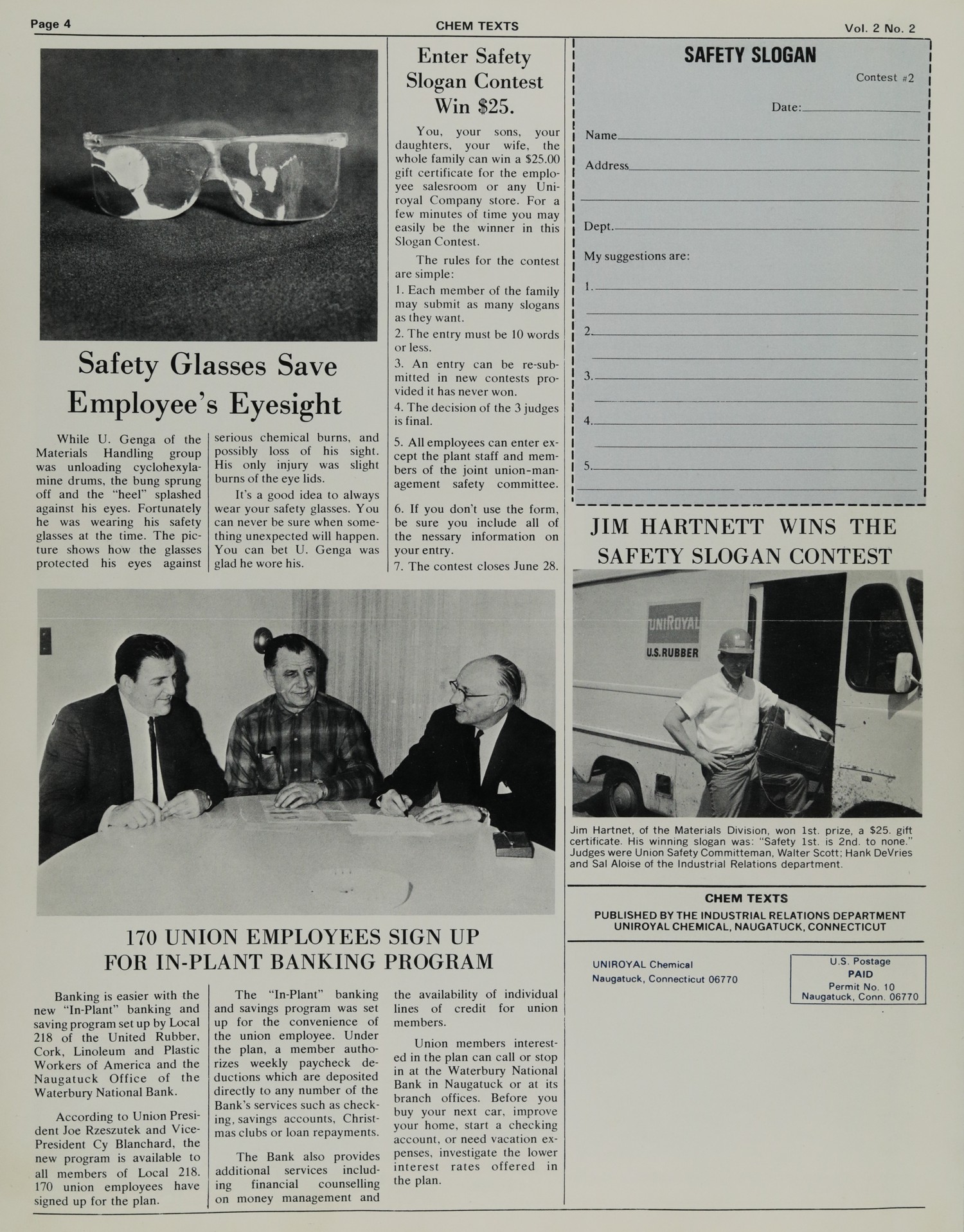

JIM HARTNETT WINS THE SAFETY SLOGAN CONTEST

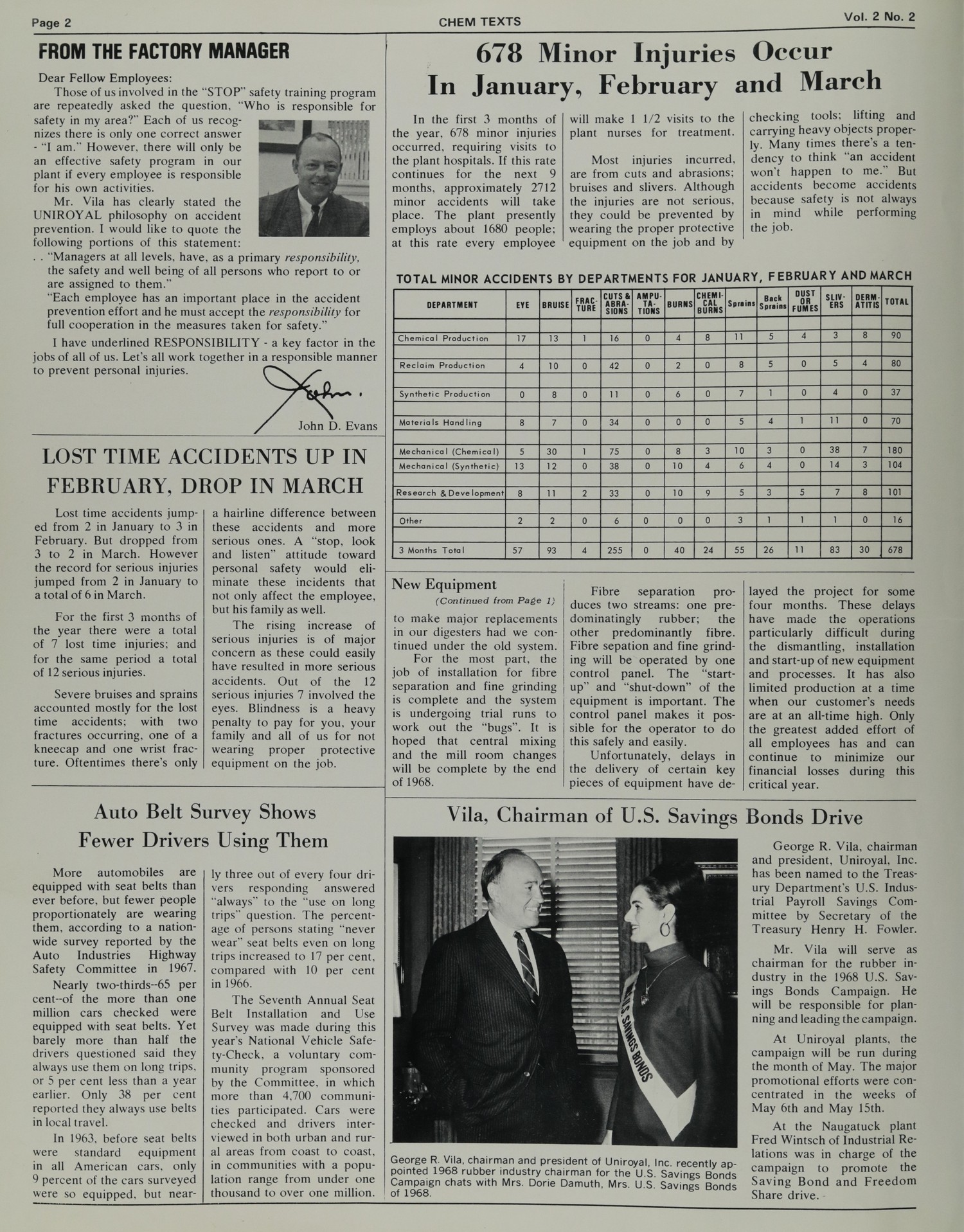

Safety Glasses Save Employee’s Eyesight

While U. Genga of the Serious chemical burns, and possibly loss of his sight. His only injury was slight burns of the eye lids. It’s a good idea to always wear your safety glasses. You can never be sure when something unexpected will happen. You can bet U. Genga was glad he was wearing his safety glasses at the time. The picture shows how the glasses protected his eyes against what he had to deal with.

170 UNION EMPLOYEES SIGN UP FOR IN-PLANT BANKING PROGRAM

Banking is easier with the new “In-Plant” banking and saving program set up by Local 218 of the United Rubber, Cork, Linoleum and Plastic Workers of America and the Naugatuck Office of the Waterbury National Bank.

According to Union President Joe Rzeszutek and Vice-President Leo Blanchard, the new program is available to all members of Local 218. 170 union employees have signed up for the plan.

The “In-Plant” banking and savings program was set up for the convenience of the union employees. Under the plan, a member authorizes weekly paycheck deductions which are deposited directly to any number of the Bank’s services such as checking, savings accounts, Christmas clubs or loan repayments.

The Bank also provides additional services including financial counseling on money management and the availability of individual lines of credit for union members.

Union members interested in the plan can call or stop in at the Waterbury National Bank in Naugatuck or at its branch offices. Before you buy your next car, improve your home, start a checking account, or need vacation expenses, investigate the lower interest rates offered in the plan.

—