## Page 001

CHEM-TEXTS

PUBLISHED FOR THE PEOPLE OF UNIROYAL CHEMICAL

Vol. 2 No. 5

New Chemical Holds Apples On Trees; Alanap, Dyanap Sales Volume

Makes Them Firmer, Redder In Color Expected To Increase In 1969

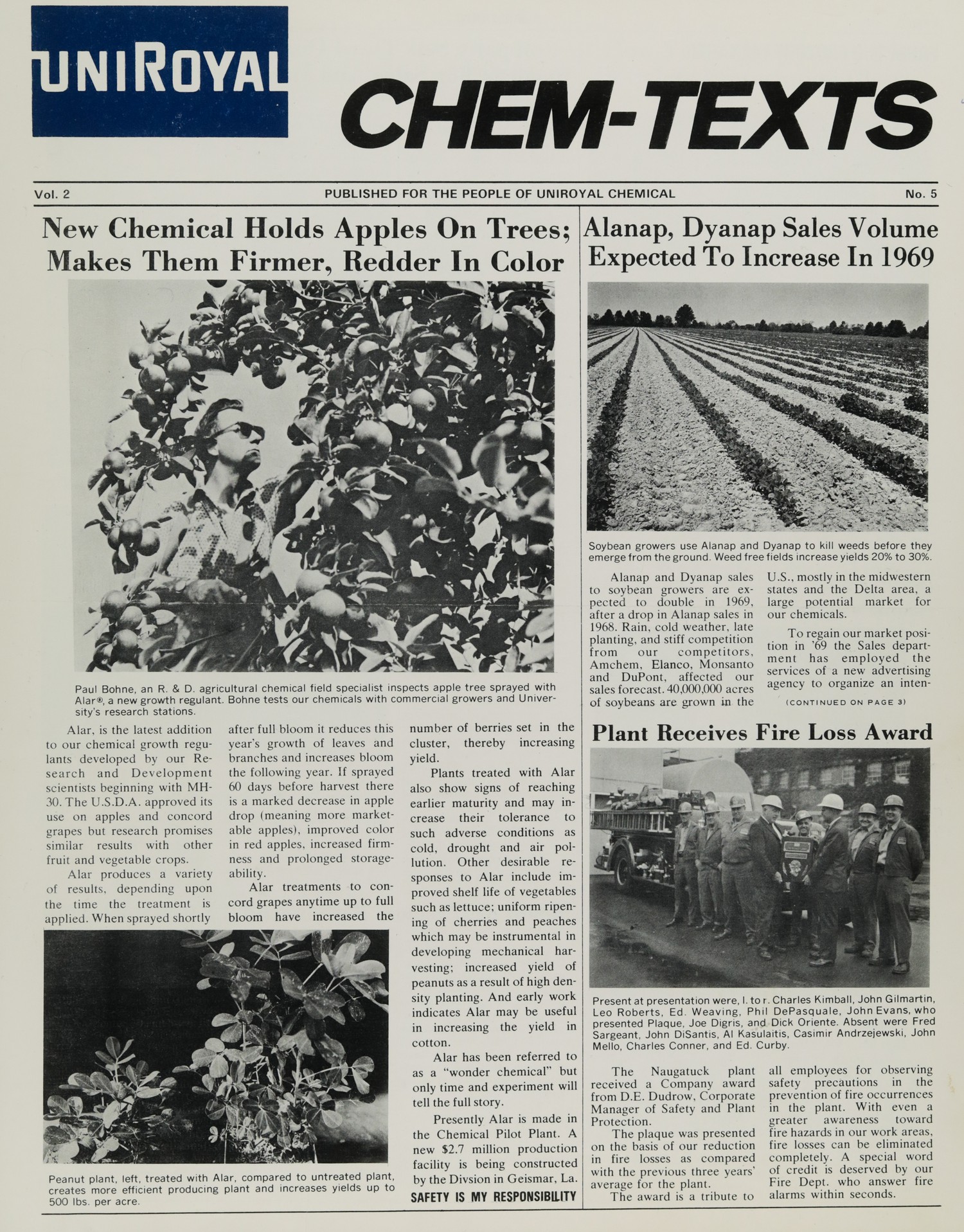

Paul Bonne, an R & D agricultural chemical field specialist inspects apple tree sprayed with

Alar, a new growth regulant. Bonne tests our chemicals with commercial growers and University research stations.

Alar, is the latest addition

to our chemical growth regulants developed by our Research and Development

scientists beginning with MH-30. The U.S.D.A. approved its

use on apples and concord

grapes but research promises

similar results with other

fruit and vegedable crops.

Alar produces a variety

of results, depending upon

the time the treatment is

applied. When sprayed shortly

after full bloom it reduces this

year’s growth of leaves and

branches and increases bloom

the following year. If sprayed

60 days before there there

is a marked decrease in apple

drop (meaning more marketable apples), improved color

in red apples, increased firmness and prolonged storageability.

Alar treatments to concord grapes anytime up to full

bloom have increased the

number of berries set in the

cluster, directly increasing

yield.

Plants treated with Alar

also show signs of reaching

earlier maturity and may increase their tolerance to

such adverse conditions as

cold, drought and air pollution. Other desirable responses to Alar include improved shelf life of vegedables

such as lettuce; uniform ripening of cherries and peaches

which may be instrumental in

developing mechanical harvesting; increased yield of

peanuts as a result of high density planting. And early work

indicates Alar may be useful

in increasing the yield in

cotton.

Alar has been referred to

as a “wonder chemical” but

only time and experiement will

tell the full story.

Presently Alar is made in

the Chemical Pilot Plant. A

new $2.7 million production

facility is being constructed

by the Division in Germany. La.

Soybean growers use Alanap and Dyanap to kill weeds before they

emerge from the ground. Weed-free fields increase yields 20% to 30%.

Alanap and Dyanap sales U.S., mostly in the midwestern

states and the Delta area, a

are expected to double in 1969, large potential market for

after a drop in Alanap sales in our chemicals.

1968. Rain, cold weather, late

To regain our market posiseason and increased competition tion in ’69 the Sales deparfrom our competitors, ment has employed the

Amchem, Elanco, Monsanto services of a new advertising

and DuPont, affected our agency to organize an intersales forecast: 30,000,000 acres sive campaign to promote

of soybeans are grown in the our chemicals.

Plant Receives Fire Loss Award

Present at presentation were: l tor. Charles Kimball, John Gilmartin,

Leo Roberts, Ed Weaving, Phil DePasquale, John Evans, who

presented Plaque; Joe Diggs, and Dick Oriente. Absent were Fred

Sargeant, John DeSanti, Al Kasulatis, Casimir Andrzcjewski, John

Mello, Charles Connor, and Ed Curby.

The Naugatuck plant all employees for observing

received a Company safety precautions in the

award from D.E. Dudrow, Corporate prevention of fire occurrences

Manager of Safety and Plant in the plant. With even a

Protection.

greater awareness toward

The plaque was presented fire hazards in our world,

on the basis of our reduction we take pride in the

in fire losses as compared initiative of our Naugatuck

with the previous three years’ Fire Dept. A special word

average for the plant. of commendation is

The award is a tribute to deserved by our Fire Dept.

who answer fire

alarms within seconds.

—

## Page 002

FROM THE FACTORY MANAGER

Dear Fellow Employee:

Technological advances, especially those over the past twenty to thirty years, have greatly outpaced our ability to understand each other. While new communication devices, such as television and the computer, have expanded our ability to send messages faster, this has been done to make sure that these messages are received only when it is understood and the intended purpose of the message is accomplished. Man’s inability to complete this communication cycle is largely responsible for the many problems that face society today.

The recent company-wide survey conducted by Opinion Research, in which many of our people took part, has confirmed that we at UNIROYAL are no different in this respect. To accomplish our objectives of growth and job security for all we must — send, receive and thereby reach understanding of our common objectives. While our efforts may be aided by CHEM-TEXTS, letters and other tools, success can only be achieved if we each, as individuals, regardless of our jobs, learn to talk to each other. We must always remember that communication is a three-way street — UP, DOWN and SIDE-WAYS. While we each may momentarily have different points of view, fair interchange of these points of view will always clarify the larger purpose.

Sincerely,

John D. Evans

Moniz’s Hard Hat Prevents Injury

Joe Moniz, a light shows assistant of the Safety Department, had a slight mishap while opening a chain valve for the 117 reclaim digester. He changed a piece of rubber gasket and the shift in the Reclaim Digest-ing Department. He changed his clothes and put on all his proper protective equipment, which included his hard hat. Joe didn’t expect an accident that might but he was prepared for the “unexpected happening”.

While opening a chain valve, the piece of rubber gasket fell 15 feet and would have fallen on his head. Fortunately, his hard hat prevented a very serious head injury. Moniz’s hard hat saved him and his family considerable anguish and suffering because he wore the proper safety equipment for his job.

Company Sets Third Quarter Records For Sales And Income

Universal, Inc., set new financial records in sales and net income during the third quarter of 1968 despite heavy start-up expenses for several new plants under construction in the United States and abroad.

George R. Villa, chairman and president, reported today.

Net income for the third quarter was a record $12,769,000 or 93 cents per common share, 68.8 per cent above the $7,563,000 or 51 cents a share reported last year.

Net income for the nine-month period was $42,805,000, equivalent to $3.11 per share of common stock, an increase of 12.5 per cent compared with the $38,663,000 or $1.20 per common share reported in the same period a year ago.

PINK COLOR CARS ARE THE SAFEST

A Swedish color expert surveyed 31,000 auto collisions and found that black cars are up to 10 times as likely to be involved in accidents as light or bright colored cars.

Pink was the safest color, involved in only 2.0% of the accidents.

Next to black, the most dangerous colors were all shades of brown and gray. Dark colors were more susceptible to collision because they are the hardest to see against a background of trees or buildings, especially at dusk.

New Maintenance Control Center Speeds Up Repairs

In October, a new maintenance control center was initiated at the Chemical plant for the planning and scheduling of work in the Chemical and Reclaim plants.

The Center is similar to the Synthetic control center which has been in operation for five months. The center will be in Bldg. 7 and manned by a staff of four people.

The basic purpose of this system is the organization of communications to and from the maintenance department and all other related plant departments, requiring services, information, it will be easier to plan and coordinate related work, establish priorities, and take advantage of the flexibility of crews. In addition, job information is accumulated for incorporation with electrical data processing which collects data and disseminates reports for future job planning, preventive maintenance evaluation and budgeting.

The broad objectives of this system are: 1) to provide better service; 2) minimize lost time; 3) reduce maintenance costs; and 4) optimize use of manpower, tools, equipment and material.

Board of Directors Recommend 2 For 1 Stock Split

The board of directors of Uniroyal, Inc. voted to recommend to stockholders that the present common stock of the company be split two shares for one. George R. Villa, chairman and president, announced.

The board called a special meeting of the stockholders for January 14, 1969, to obtain stockholder approval of the proposed split.

The board also declared a quarterly dividend of 30 cents a share on the common stock, payable December 24 to stockholders of record November 25. The board of directors also announced that the company’s common stock has split two-for-one.

The board recommended the stock split with the expectation that it would broaden the market for the company’s shares and increase the number of shareholders. The company now has approximately 49,000 common stockholders.

At the board meeting the directors also declared a dividend of 52 a share on the first preferred stock, also payable December 24 to stockholders of record November 25.

Special Xmas Offer:

Royal Golf Balls

A special Christmas offer of ROYAL Golf balls is available to all Company employees. Orders should be placed with the Employees Salesroom on Rubber Avenue from now till Dec. 15. Prices per dozen are: ROYAL Red at $9.25; ROYAL Queen at $9.25; and FAIRWAY II at $5.45.

The bonus golf ball policy does not apply to this special offer.

Next to black, the most dangerous colors were all shades of brown and gray. Dark colors were more susceptible to collision because they are the hardest to see against a background of trees or buildings, especially at dusk.

SAFETY IS MY RESPONSIBILITY

—

## Page 003

Page 3

CHEM TEXTS Vol. 2 No. 5

Give

20,646

TED WAY

Uniroyal Chemical’s United Fund Campaign Committee looks at the “thermometer” showing the results of the drive at the plant where employees topped their goal by 103%. Left to right are Doug Miller, Sam Gillette, Bob Vanallen, the Industrial Division’s Chairman, Joe Rzeszutek, Ron Mitchinson, pointing to the $20,646 figure and Bill Lavelle. Other committee members not in the photo were Ed Allsup and LeRoy Johnson.

Employees Contribute $20,646.

Top United Givers Goal By 103%

Ron Mitchinson, Chairman of the United Givers Campaign at the Naugatuck plant, announced that employees contributed $20,646 or 103% topping the plant’s Goal of $20,000. This surpasses by almost $3,000 the previous high of $17,737.

New Food Vendors Service Plant

By Monday, December 2nd, all food and beverage vending machines in the plant will have been replaced with brand new machines to provide plant employees with better food service.

The new firm, Indiana Vendors, has proposed several basic changes which will eliminate the problems we have experienced in recent months: machines out of order, only or not giving change, machines stuck, and a generally high refusal rate of uniform new quality. There will be an on-site maintenance man who will be in charge of keeping all machines operating properly in all respects. All food will be prepared and wrapped in the Synthetic Plant kitchen facilities. This means that food in the machines will have been prepared in our own kitchen one or two before being put into the vending equipment. It also means that when more departments than usual are scheduled to run over a weekend or holiday, extra sandwiches can be prepared at the last minute and placed in the machines. If the machines are out at 2:00 P.M., it can be filled out before the next day.

The machines will be the latest in design and efficiency. Take the office machines for example. You put your coin into the machine, select the way you want your coffee.

and receive a cup of fresh, hot coffee. The machines will operate on 1/3 lb. cans of Maxwell House coffee exactly the same grind you buy for home use. Approximately 20 cups are perked and then transferred to a holding chamber. After a preset lapse of time, a new batch is made to maintain the holding chamber. The coffee is always fresh. No more instant coffee.

The food machines will also hold a wider variety of food. Soup will be sold with the can, bowl, spoon, cracker and napkin as a package – all you never run into the selling station where, having purchased a can of soup, no spoon or dishes are available.

Some of the areas in the plant will be expanded or have more versatile machines such as canned soda or flavor ice vending machines – the kind they have in Reclamation Building. The Shipping will have a sandwich machine, for example, and a coffee machine will be put into the Chemical Machine Shop where up to now only a cigarette machine has been in operation.

In short, new and better machines, with better service and more and better food, will give you the best food service available.

Harry Witt Heads

Synthetic

Production

Harry Witt has been named Synthetic Production Superintendent, effective Dec. 1. Ben Leach becomes Manager of Colonial products in the Research and Development Dept.

Accidents Continue

At High Rate

In the ten months of this year, 79 lost time and serious injuries have occurred. Three of these resulted from a careless act or operation. We each must accept responsibility for our own actions that effect safety of all.

MONTH

LOST

TIME

INJURIES

SERIOUS

INJURIES

TOTAL

JANUARY

3

2

5

FEBRUARY

3

2

5

MARCH

2

4

6

APRIL

2

6

8

MAY

0

11

11

JUNE

2

5

7

JULY

2

7

9

AUGUST

4

4

8

SEPTEMBER

0

3

3

OCTOBER

1

6

7

TOTAL

17

50

67

ALANAP AND DYANAP (con’t.)

(CONTINUED FROM PAGE 1)

sive advertising and promotional program for our distributors and dealers. Grower meetings will be conducted by our sales force demonstrating the advantages of Alanap and Dyanap products over competitive items.

Quality products play an extremely important role in the agricultural business. A poor quality product damages a grower’s crop, the reputation of the product and the Company. Important also in the farm market is good packing and packaging. Good packing reduces our sales. Dented or stained cans, torn and dirty bags convey the impression of poor quality and workmanship in the customer’s mind. Good quality and good packaging can help make 1969 a record year in Alanap and Dyanap sales.

How You Can Obtain A Pair

Of Safety Prescription Glasses

Fred Mayo of the Process Development Lab, selects glasses for safety nurse.

The Naugatuck plant has a program which is operated by the Safety Department to enable all Chemical division employees to obtain safety glasses at no cost to the employee, except for the examination and fitting. The procedure is simple.

An employee may go to either the Chemical or Synthetic hospital and obtain a prescription safety glass form from the nurse. He takes the form to the Wilkie Optical Company and purchases the glasses. The Company then sends the prescription to the Wilkie Optical Company and purchases the glasses.

Effective January 1, 1969, all prescription glasses must be returned to the doctor or chemical division, for proper checking and fitting. In certain cases an additional charge may be made, depending upon the agreement you have made.

Here are other facts you should know: 1. You may buy an extra pair of glasses for yourself, if you wish and take advantage of our Company discount, provided the prescription is less than one year old. 2. You may also purchase prescription glasses at the same discount.3. You may obtain a free pair of glasses whenever you require a new prescription. Lenses or frames damaged as the result of an accident at the plant will be replaced free of charge.

Clark Retires From Mechanical

Ed Clark, left, is congratulated by Bill Lannon, Foreman of the Instrument Department. Clark, an instrument man in the Mechanical Department, retired recently after more than 22 years with the Company.

SAFETY IS MY RESPONSIBILITY

—

## Page 004

Employees Receive $1,453. In Awards For Recent Suggestions

Dom Persutti Submits Nine Suggestion Winners

Eighty-two suggestions received cash awards or honorable mentions in the last three months, amounting to a total of $1,453.00.

The highest award of $170.00 went to L. Schiller; $120.00 to R. Raymond; $100.00 to K. Anderson and K. Nelson splitting another $100.00 award for their suggestion.

D. Persutti was the top idea man submitting 9 suggestions, receiving $75.00 in awards and 4 honorable mentions. J. Sullivan and W. Campbell each submitted 4 suggestions and were awarded $45.00 and 1 honorable mention for their ideas.

Other employees who received high awards for their suggestions were J. DiSantis, $53.00; W. Adamski, $50.00; and Mary Marques, $35.00 awards.

$25.00 awards went to W. Bedard, F. Chodo, A. Calder, E. Root, E. Bazenas, and A. Patska.

$15.00 awards were given to R. Shipman, F. Carriero, G. Ravenscropt (3 awards), R. Harrison, J. Tannuzi, B. Jones, W. Frum, S. Martinelli, W. Knight, A. Gednatis, F. Commentator, D. Pratt (2 awards), B. Torrey, J. Dayneer, L. Fortier, W. Stenson, A. Civello, L. Raskeuskas, A. Kazemekas, E. Saviel, E. Root, E. Miele, F. Surmanek, F. Bentler, Z. Vaitkus, K. Reuine, and J. Johnson, G. Monahan, B. Prandis, R. Harrison, J. Hoey, and A. Silva.

Lou Schiller of R & D received $170.00 for his suggestion that Teflon bearings be used on Money machines to reduce costs.

Ken Anderson, left, and Ken Nelson of the Synthetic Mechanical Dept. received $50 each for suggesting that the hydraulic jet pump’s speed be reduced to one-third to reduce maintenance costs.

Ed Bazenas of the Mechanical Dept. received two awards on suggestions on equipment improvement in BLISS, 80 and 105.

Honorable Mentions were received by L. Bissonette, J. Grosso (2), J. Ferguson, C. Ianmuzi, J. Reb, D. Danto, E. Rott (2), L. Anderson, E. Bazenas, P. Masne, W. Frum and G. Monahan.

Any employee can participate in the Company wide Suggestion System plan. The suggestion should be original and represent thinking beyond that expected on the job.

SAFETY SLOGAN

Contest #5

Date: _________________

Name: ________________

Address: ______________

Dept.: ________________

My suggestions are:

1. ____________________

2. ____________________

3. ____________________

4. ____________________

5. ____________________

Ray Pekock Wins $25. For Safety Slogan: Contest Open To All Members Of Family

“Safety First, Make It A Way” was the winning safety slogan submitted by Ray Pekock, Other employees entering the contest with interesting slogans were Linda Lasky, James Harriett, and Cynthia Haggerty. The winner, Lynda Nappiello, Cynthia Haggerty, Bill Schmalle, another contest winner. Richard Frangiamore, Tom Basile, and Barbara Gabriel.

More and more interest in the contest with more than a 100 safety slogans submitted. Many of the slogans have come from members of employees’ families. Any member of an employee’s family is eligible to win the $25. award.

The rules for the contest are simple. All slogans should be sent to the Safety Dept., BLISS, where they will be judged by three members of the plant’s Safety Committee.

1. Each member of the family may submit as many slogans as they want.

2. The entry must be 10 words or less.

3. An entry may be re-submitted in new contests provided it has never won.

4. The decision of the judges is final.

5. Entries close Dec. 20.

CHEM TEXTS

PUBLISHED BY THE INDUSTRIAL RELATIONS DEPARTMENT UNIROYAL CHEMICAL, NAUGATUCK, CONNECTICUT

UNIROYAL Chemical

Naugatuck, Connecticut 06770

RETURN POSTAGE GUARANTEED

U.S. Postage

PAID

Permit No. 10

Naugatuck, Conn. 06770

George Ravenscropt who works in the Instrument Dept. was awarded $30.00 for a safety and maintenance suggestion.

Your ideas can cover such areas as new or better products, improved quality, better packaging, savings of production time, better working conditions, scrap reductions, material savings, simplified working procedures, and many other possibilities.

Suggestion System forms are located conveniently throughout the plant.

SAFETY IS MY RESPONSIBILITY

—