## Page 001

CHEM-TEXTS

Vol. 3

New Plant Entrance Nears Completion

Plant’s Security Is Tightened Up.

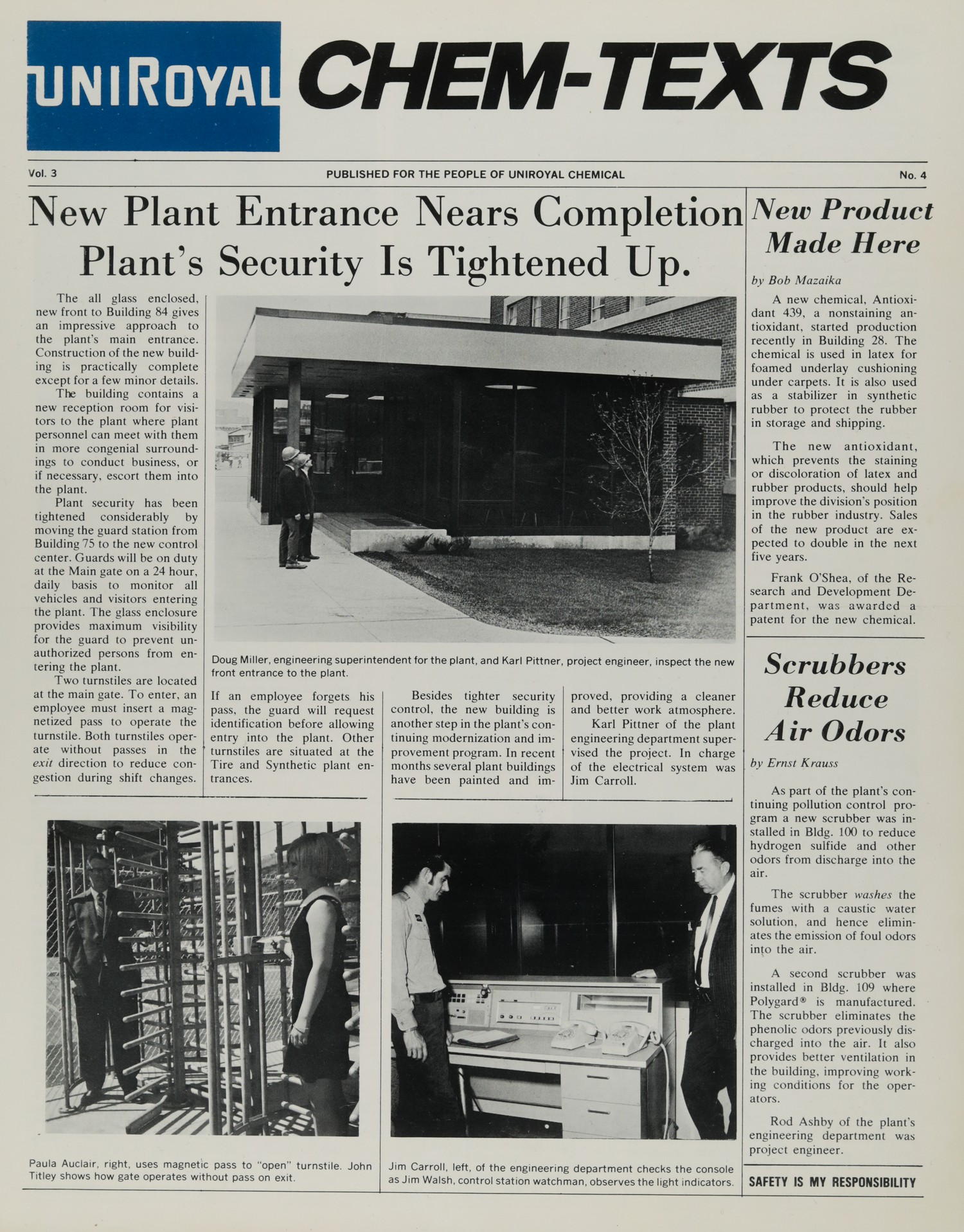

The all glass enclosed, new front to Building 84 gives an impressive approach to the plant’s main entrance. Construction of the new building is practically complete except for a few minor details.

The building contains a new reception room for visitors to the plant where plant personnel can meet with them in more congenial surroundings to conduct business, or if necessary, escort them into the plant.

Plant security has been tightened considerably by moving the guard station from Building 75 to the new control center. Guards will be on duty at the Main gate on a 24 hour, seven day a week basis for all vehicles and visitors entering the plant. The glass enclosure provides maximum visibility for the guard to prevent unauthorized persons from entering the plant.

Two turnstiles are located at the main gate. To enter, an employee must insert a magnetized pass to operate the turnstile. Both turnstiles operate without passes in the exit direction to reduce congestion during shift changes.

No. 4

New Product

Made Here

by Bob Mazaika

A new chemical, Antioxidant 439, a nonstaining antiozonant, started production recently in Building 28. The chemical is used in latex for foamed underlay cushioning as a stabilizer in synthetic rubber to protect the rubber in storage and shipping.

The new antioxidant, which prevents the staining or discoloration of latex and rubber products, should help improve the division’s position in the rubber industry. Sales of the new product are expected to double in the next five years.

Frank O’Shea, of the Research and Development Department, was awarded a patent for the new chemical.

Scrubbers

Reduce

Air Odors

by Ernst Krauss

As part of the plant’s continuing pollution control program a new scrubber was installed in Bldg. 109 to reduce hydrogen sulfide and other odors from discharge into the air.

The scrubber washes the fumes with a caustic water solution, and hence eliminates the emission of foul odors into the air.

A second scrubber was installed in Bldg. 109 where Polygard® is manufactured. The scrubber eliminates the phenolic odors previously discharged into the air. It also provides better ventilation in the building, improving working conditions for the operators.

Rod Ashby of the plant’s engineering department was project engineer.

SAFETY IS MY RESPONSIBILITY

—