## Page 001

Merry Christmas – Happy New Year

CHEM-TEXTS

Vol. 4, 1970 PUBLISHED FOR THE PEOPLE OF UNIROYAL CHEMICAL No. 10

Real Christmas Spirit

Girls in the IBM Tabulating department add a touch of Christmas spirit to the office. Adjusting the wreath which they made, are from left, Julie Griffin, Joyce Lenizucci, Helen Southard and Edna Gryzcyc.

Unique Company Formed Sales Drop; Profits Off

Sales of UNIQUE Disco Delic Lite conducted at the Chemical plant were highly successful before several hundred dollars. From left to right are Jim Gelking, Lou Schiller, Gail Snedeker, Joe Rezzutek, URW Legal 218 President, Gail Murray, Nancy Murdock, Cathy Carson, Ron Stark, Advisor, and Sonya Kemesaric.

Unique is not only the name of the Junior Achievement Com-pany sponsored by Uniroyal Chemical but also the description of the Company’s unusual product, a Disco Delic Lite.

N.H.S. Students Head Firm

The lamp was designed, man-

Uniroyal, Inc. sales and profits dropped during the 3rd quarter due to the auto strike and continued setbacks in the chemical, rubber, plastics and latex industries. The GM strike forced production cutbacks in several areas, plastic products, and chem-ical plants. Reduced the produc-tion hurt the sales of many products made in Chemical and Reclaim Production for tire manufacturers.

Company sales dropped $3,000,000 for the 3rd quarter and profits were off $3,149,000, compared with the 3rd quarter of 1969.

During the 9 month period of 1970 the Company suffered a $17,894,000 loss in sales com-pared to 1969.

Profit for the 9 months of 1970 dropped $10,332,000 compared to 1969.

Higher interest charges and higher costs for labor and raw materials, which cannot be passed on to the customer, also affected the Company’s profits.

Theory In Practice

The textbook theories of eco-

Omite Facilities Constructed; Productivity Quality Improved

D. Beretta,

Chemical

President

David Beretta, Factory Man-ager of the Naugatuck plant from 1965-1966, was named Vice-President of Uniroyal, Inc. and Divisional President of Uni-royal Chemical, succeeding Frank A. Hopkins, who resigned from Uniroyal.

Mr. Beretta joined Uniroyal in 1952 as a process develop-ment engineer in plastics and rubber at the Naugatuck plant. He held several positions in polymer Research and Develop-ment until named Synthetic Produc-tion Superintendent. In 1965 he was appointed Factory Manager, a position he held until 1966 when he was transferred to Can-ada as a Vice President and General Manager.

Construction of new Omite facilities helped increase productivity and improve the quality of the chemical. Standing in front of new refrigeration units are three of the Omite operators who helped installing these significant improvements in the quality: from left, Leroy Bostovero, Ed Chernicky, Deirne Huntley and Bob Brotton, foreman.

Utilities was instrumental in significantly increasing Omite pro-ductivity and quality.

Quality Improved

Since Jan. 1969

Since January 1969, the qual-ity of Omite has improved signif-icantly and is now excellent. This outstanding quality and production performance is at-tributable to the men who

(Cont’d on page 3)

Dividend Declared

Uniroyal declared a quarterly dividend of 17% cents a share on the common stock, payable De-cember 24 to stockholders of record November 23.

The Company also declared a dividend of 43¢ a share on the first preferred stock, payable De-cember 24 to stockholders of record November 23.

Dr. Perry Kippur inspects new 200 HP motor on the new com-pressor for the refrigeration system in Bldg. 100.

—

## Page 002

Here is the text extracted from the document image, preserving the layout and structure as much as possible:

FROM THE FACTORY MANAGER

DEAR FELLOW EMPLOYEE:

Christmas is the season when everyone of us express more than anything during the year, the spirit of giving and concern for our family, friends, and the people we come in contact with each day of our lives. This spirit is particularly reflected by gifts to our families; visits to friends’ homes, and a sharing with others the many joys of the holidays.

In the plant where all of us work so closely together and depend upon each other so completely, this same spirit of giving and concern is vital.

By giving out fullest effort to, and showing the utmost concern for our responsibilities and the people we work with, each of us can individually infuse into the plant a spirit that will really make it a good place to work. The plant is not just a mere collection of buildings which house equipment to help us produce products or provide services, it is us, our efforts and our achievements.

Our work takes up more than eight hours of our day, and is a major part of our life. We can make it challenging; we can make it more secure; we can make it more enjoyable by the same spirit of giving and concern that we display during the Christmas season.

I sincerely hope that you and your family, will enjoy a most happy Christmas and the fullest joy and happiness during the new Year.

Sincerely

S. Salman

Chlebowski Averts Fire

by Ed Bearing

Matty Chlebowski’s quick action averted a serious fire in the Captains department. Chlebowski opened a waterlog valve over a mixing tank which controlled some undissolved sulfur and carbonbisulfide.

The incident occurred during cleaning operations to remove undissolved sulfur and carbonbisulfide out of the mixing tank. Operators had removed the manhole cover to check the contents and started to add water through the manhole. The escaping carbonbisulfide ignited, producing a hot steam pijr and the flash fire burned a supervisor’s face and arms, which required hospital attention.

Tom Long, a member of the crew, turned in the fire alarm signal to the plant protection department. “The fast action and alertness of Chlebowski and the entire crew in an emergency prevented more serious damage from occurring.” said Tom Engle, foreman of the building Maintenance crew working on the second shift under Frank Manuse, Charlie Drapka, and Ed Aulbing.

During cleaning operations, tanks with hazardous vapors should always remain closed to prevent their escape.

SAFETY IS MY RESPONSIBILITY

Oxford Office Close to Completion

Construction of the administration building of Uniroyal’s Oxford Complex is on schedule for occupancy in summer. With most of the exterior work completed, and much of the interior draftwork, wiring and piping installed, the first of several buildings to be constructed will house many of the corporate activities presently in New York, EMIC, and Professional Park.

1,100,000

Man Hours . . .

It Happens

1,100,000 manhours were worked without a lost time accident for the second time this year. The most recent occurred from July to November when 1,100,000 manhours were reached without a lost time accident.

On November 29th, the record was broken a 2nd time injury when an operator shoveling residue in a change ditch under a fiber separation mill, strained his muscles in his back.

Only four lost-time accidents occurred this year, a major improvement over 1969 when 23 employees were injured and lost time from work.

Serious Injuries

The rate of serious injuries is about the same as last year. To date 56 serious injuries have place while 52 occurred in 1969.

“What Close Calls Happen To Me”

A “won’t happen to me” attitude still exists among many employees who stubbornly resist safety habits.

Three Steps

Taken To

Improve Air

Three steps have been taken to pollution control pollution of the air. A new tower type scrubber was installed in Bldg. 109 at a cost of $40,000. The scrubber, by washing the phenolic fumes, eliminates the emission of these objectionable odors into the atmosphere.

A process change in Bldg. 28 where PBNA is manufactured will eliminate the amine odors discharged into the atmosphere and improve this process. This change is scheduled for completion by April.

A new Dust Collector has been ordered for one of the mills in Bldg. 50 of Chemical Production. It will collect the fines which presently escape into the atmosphere.

Plant Water

Cost Up 13%

The plant’s water costs were increased 13% due to a rate rise by the Connecticut Water Co. The new increased rates will affect the plant’s operating costs about $55,000 annually.

Currently, 55,000,000 gallons of water a month are used by the Chemical and Synthetic plants. In one year, 69,000,000 gallons were used; and in 1971, 60,000,000 gallons were consumed.

Water costs for the plant presently run $143,900 a year, and average $12,000 a month.

Help Conserve Water

Use of water, only when needed, will conserve it and keep the plant’s water bill down. Water waste increases operating costs and cuts into the plant’s profit. In some products it can seriously affect the cost of the product, including us competitively.

Considerable water can be saved by shutting off equipment when not in use, especially on weekends. Water hoses are also a major factor in water waste, when used to wash spillage down the drain. Dry spills should be swept rather than washed with the hose.

Every employee can help by turning off faucets, repairing leaks; and by using only as much water as is necessary to do the job.

Broden Named VP

Bill Broden, a Process Engineer in Chemical Production, was named Vice-President of the Uniroyal Chemical Management Club. Broden replaces Jim Mulligan who was transferred to Frank Manuse, John McManuss, Charlie Drapko, and Ed Aulbing.

General Manager of Canadian chemical operations. Later he became marketing Vice President for all Uniroyal products sold in Canada, a position he held until appointed Vice President of the Chemical Division.

Mr. Beretta will be the guest speaker at the Uniroyal Chemical Management Club meeting on Jan. 20 at Berlin’s Restaurant.

Sales Drop;

Strong competition in chemical, reclaimed rubber, synthetic rubber and latex industries prevent passing on automatic price increases to our customers without the risk of losing their business. The extra cost of operating the plant must be absorbed by increased productivity; prevention of waste; and the reduction of obsolete materials that have to be reprocessed at an extra cost and that substantially affect the plant’s profit on the product.

—

## Page 004

Page 4

CHEM-TEXTS Vol. 4 No. 10

First A Friend . . . Then A Host

1,100,000 . . .

(Cont’d from page 2)

protecting themselves against un-

expected accidents. They not

only endanger their own physi-

cal protection but expose their

families and fellow employees to

unnecessary suffering and finan-

cial loss. Safety equipment and

clothing should always be worn

where required to prevent an

unexpected accident on the job.

Unique Co.

(Cont’d from page 1)

nomics are simplified by prac-

tical application in organizing a

company, raising capital through

stock, design and research of the

product, purchase of raw materi-

als, salaries, insurance, and a

return on investment to their

stockholders.

Any high school student may

join a J.A. Company through

their high school and discover

for themselves the many inter-

esting career opportunities in

business.

Advisers to Unique are Jim

Chambers, Mike Jasman, Lou

Kaiser and Roy Stark, who pro-

vide the technical and financial

knowledge to the company.

Chemical

Business

(Cont’d from page 3)

equipment; so that we can con-

tinue to grow and protect job

security.

New Products Promising

The Chemical Division has

many promising products for the

future. Royalene® is used in

plastic garden hoses, vinyl water-

walls, and it could become an

even bigger factor in tires.

Solo®, Dyanap®, and Omite®

showed good growth in 1970.

Telephones and many of your

home appliances are made of

Kralastic® ABS plastic, 25% of

the houses built today in the

United States have Kralastic

drain, waste and vent piping.

Although some of these prod-

ucts are made at other Chemical

division plants, their sales

growth is important to the Nau-

gatuck plant which manufac-

tures many of the chemicals

used in these products.

Cooperative Effort Needed

Markets for our products will

grow as long as we satisfy our

customers; meet our competi-

tion; and produce quality prod-

ucts at the lowest possible cost.

The Marketing and Sales De-

partment are constantly seeking

new customers and developing

new markets for our products.

With the continued cooperation

of Research & Development; the

Plant’s production capabilities

and the Sales department, we

can stay ahead of competition.

Matos, David, Marinello,

And Dr. Tate Retire Recently

Number 1 in efficiency was the comment made on Maria Matos’

retirement after 26 years in Reclaim. Congratulating her, are from

left, Maria P. Silva: Bellina Nunes; Linda Oliensis; Larry Moro,

foreman; her husband Florentino, and Maria N. P. Silva. Maria never

missed a days work since 1947, twenty-three years of service

without an absence, a unique achievement.

Luis David retired from Reclaim Production after 16 years. From

left are Abraham Vendrell, Waldo Hildreth, David, and Lee

Thompson, congratulating him.

First to retire under new Pension Plan for wage employees, Flavio

Marinello, center, is congratulated on his retirement after 37 years,

From left are Jack Hoey, John Gandolfo, Flano, Dan Cleary and Jim

Lowery.

CHEM-TEXTS

PUBLISHED BY THE INDUSTRIAL RELATIONS DEPARTMENT

UNIROYAL CHEMICAL, NAUGATUCK, CONN. 06770

EDITOR: William F. Lavelle

UNIROYAL CHEMICAL

Naugatuck, Connecticut 06770

RETURN POSTAGE GUARANTEED

U.S Postage

PAID

Permit No. 10

Naugatuck, Conn. 06770

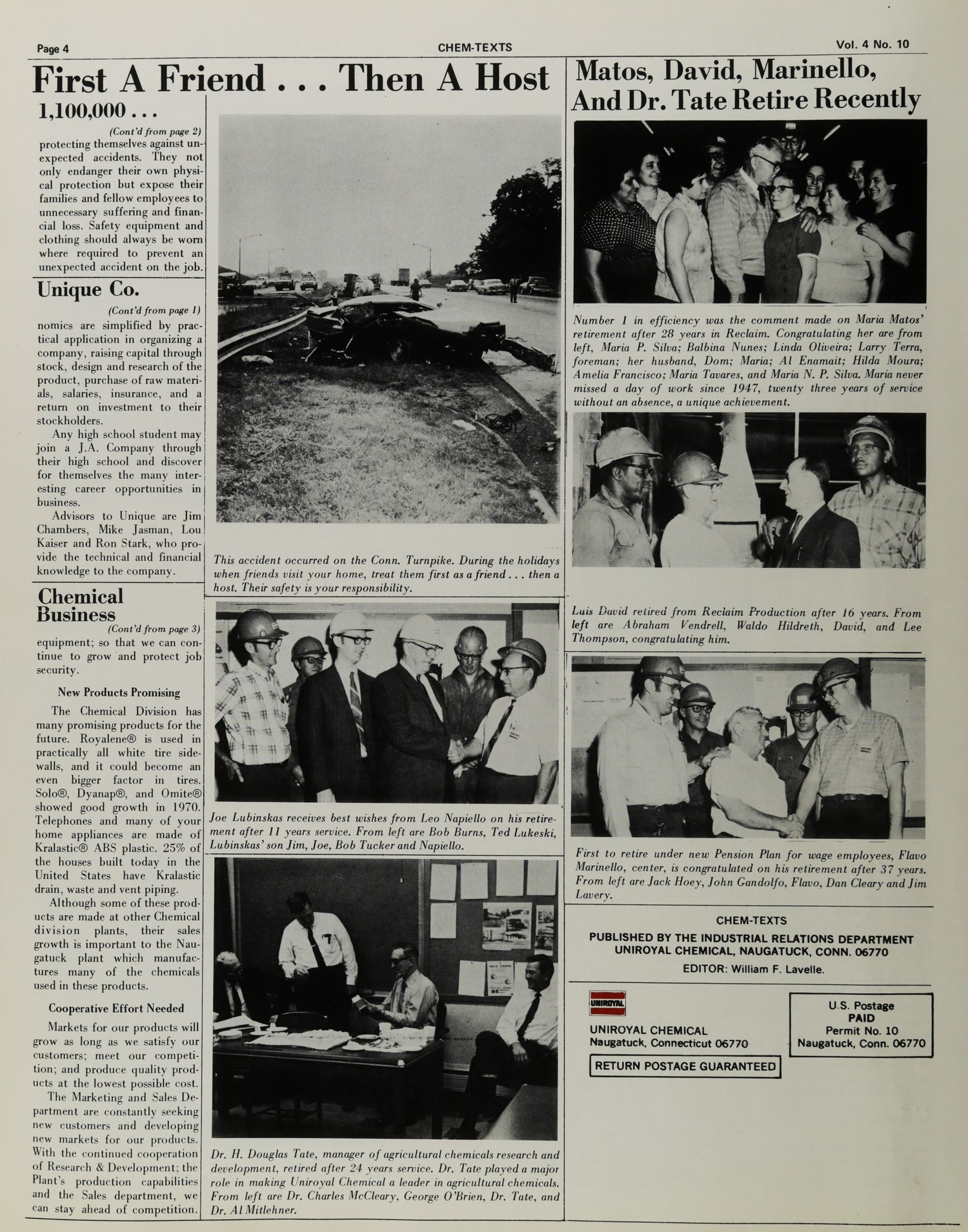

This accident occurred on the Conn. Turnpike. During the holidays

when friends visit your home, treat them first as a friend . . . then a

host. Their safety is your responsibility.

Dr. H. Douglas Tate, manager of agricultural chemicals research and

development, retired after 24 years service. Dr. Tate played a major

role in making Uniroyal Chemical a leader in agricultural chemicals.

From left are Dr. Charles McCleary, George O’Brien, Dr. Tate, and

Dr. Al Mitchener.

Joe Lubinskas receives best wishes from Leo Napolitio on his retire-

ment after 11 years service. From left are Bob Burns, Ted Lubinsky,

Lubinskas’ son Jim, Joe, Bob Tucker and Napolitio.

—

## Page 010

Chemical Business Competition Increases

Omite Facilities

(Cont’d from page 1)

worked in 1946, 1948, Bob Anderson, Joe Bednarek, Lyle Bussette, Ed Cheney, Ray Drapeau, Harry Hedrick, Oran Hensley, Dan Marino, John Merchant, Carl Milando, Dom Persanti, and Bob Breton, foreman of the building.

Reduces Pollution

By recovery of the benzene

solvent, which was previously

lost and discharged into the atmosphere and the Naugatuck

River, the plant not only saved

materials’ cost but also reduced

pollution.

Prevention of waste by dumping materials into the drain is an

important part of the plant’s

policy to stop pollution. Its success depends on every operator

carefully checking all processing

operations to prevent waste, and

to avoid wasting chemical spillage into the river.

Safer Operation

Bulk burial phenol will be

stored in one of the new 10,000

gallon tanks and piped directly

into the processing operations,

making the job easier and safer.

An operator previously lifted

and emptied 55 lb. bags, and

emptied them into the

equipment. The bags were discarded as solid waste. The new

facility now eliminates this

waste problem, another improvement in plant operation.

The other 10,000 gallon tank

holds lindol chloride, which was

previously handled in 55 gallon

drums.

The two new tanks minimize

exposure to lifting and handling

heavy objects, as well as the exposure to handling chemicals in

drums.

Lab Cat

Becomes

A Queen

Ed Geise, seated, Director of Marketing for the Chemical division reviews marketing plans with Henry Smith, left, General Sales Manager and Joe Flannery, General Products Manager, for Joe Flannery.

Business continues to be more competitive. In today’s tight economy, competitors want our customers just as

we want theirs; and they fight

pretty hard for them too. Today

there is no such thing as a guaranteed market for our products.

Competitors are often willing

to offer better delivery, packaging, quality, technical service

and even lower prices to obtain

business. And customers, on the

other hand, are increasingly

more demanding for these services and prices.

Cost-Price Squeeze

Most businesses today are in a

cost-price squeeze in the competitive struggle. Our business is

no exception. Profits have declined in the last year as a result

of lower prices for our products

and higher costs of doing business. And yet we must be increasingly responsive to our customers to keep our business and

maintain a healthy growth. At

the same time, we must be efficient and competitive to be

profitable. Profits are the source

of funds to expand our business;

to modernize plants; install new

(Continued on page 4)

Promising Product

Sales of Omite increased 10%

over 1969 sales and was a bright

spot in the plant’s economic

performance.

Phenol Spill

Causes Burn

A freak accident took place

in the Control Lab, when the

bottom of a glass test tube broke

while an analyst was stirring a

chemical in it with a glass rod.

Phenol spilled over the employee’s laboratory smock and

caused a minor burn to the skin.

The accident was a perfect

example of the unexpected happening. As a safety precaution

against such accidents, procedures should be held over the laboratory bench to avoid accidental

burns from broken glassware.

Accidents of this type are

unusual and occur only one out

of a thousand times. Prevention

of the one time is what safety is

all about.

Personnel

Assignments

Earl Root was made a Foreman in Synthetic Production.

Prior to his new assignment he

was a Utility Operator at the

Synthetic plant. Earl joined Uniroyal in 1947.

Al Hollchley was assigned to

Testing Services in Bldg. 81,

responsible for Chemical Control.

Doug Ritchie was transferred

to the Synthetic plant as a

process engineer.

DONT DRINK AND DRIVE

Eskiloos Set Style

Uniroyal’s Eskiloos are better than ever for getting around town in

style in rain and snow weather. Eskiloos come in two lengths from

ankle bone to knee high on high, thick heels. They offer wear-and-tear

resistance, water repellent protection, along with quick cleaning and

stain resistance. Many of these special attributes are due to the

Eskiloos superior material which is derived from Uniroyal’s Chem-tex,

a product of the Chemical Division. Much of the Research and

Development work on the vinyl plastic is done by the Marketing

group at the Technical Sales Service Center.

[Image caption]

Eskiloos are new in style, sales of rubber

the vinyl plastic material

have grown

have been dropped off.

drops that had been on

to determine

the sole for many years as new tests were

conducted at a cost of approximatch $750,000 before a point

mately $750,000 to the company

of the chemical was sold comof the chemical was sold commercially.

mercially.

Omite does not upset the

ecological cycle. Harmful to humans and animals, it does not

disrupt the natural, biological

control of predatory insects such

as bees which are beneficial to

growers.

—