## Page 001

Here is the text extracted from the document image, preserving the layout and structure as much as possible:

Chem World

Published by Uniroyal Chemical Co. for its Employees and Retirees January 1990

Contents

’89 Quality Symposium . . . . . . . . . 2

Uniroyal of Canada Awarded . . . 3

Preparing For Future Markets . . 4

Ingulli Plans Growth Strategy . . 5

Simon Receives Career Award . . 6

ChemWorld Briefs . . . . . . . . . . . . . 8

New Chapter Unfolds Following Management Buyout

On Monday, October 30, 1989, Uniroyal Chemical Company completed the management buyout of the company from Avery, Inc. for a price of $300 million, which signifies the beginning of a new era for the company. “This purchase has put Uniroyal Chemical’s future directly where it belongs: into the hands of those who know its business best — Uniroyal Chemical’s current management,” stated Uniroyal Chemical president and chief executive officer Robert J. Maziarka. “We believe this strengthens the company’s management position and will reinforce our reputation as an energetic, progressive and growing company with long-term vision toward the future.”

The new owners, an experienced management team with a high level of commitment to the company’s future financial success, intend to broaden its technical base and penetrate new growth markets that will enhance Uniroyal Chemical’s strategic position worldwide.

Over the past three years, the company has increased sales by 48 percent, maintained a high profit margin, and expanded its markets, both domestically and internationally. “We intend to extend Uniroyal Chemical’s solid record of aggressive growth and build on our past sales successes,” said Maziarka. “We will be looking for more opportunities for joint ventures and licensing agreements.”

Today, Uniroyal Chemical holds leading marketing positions in many of its markets.

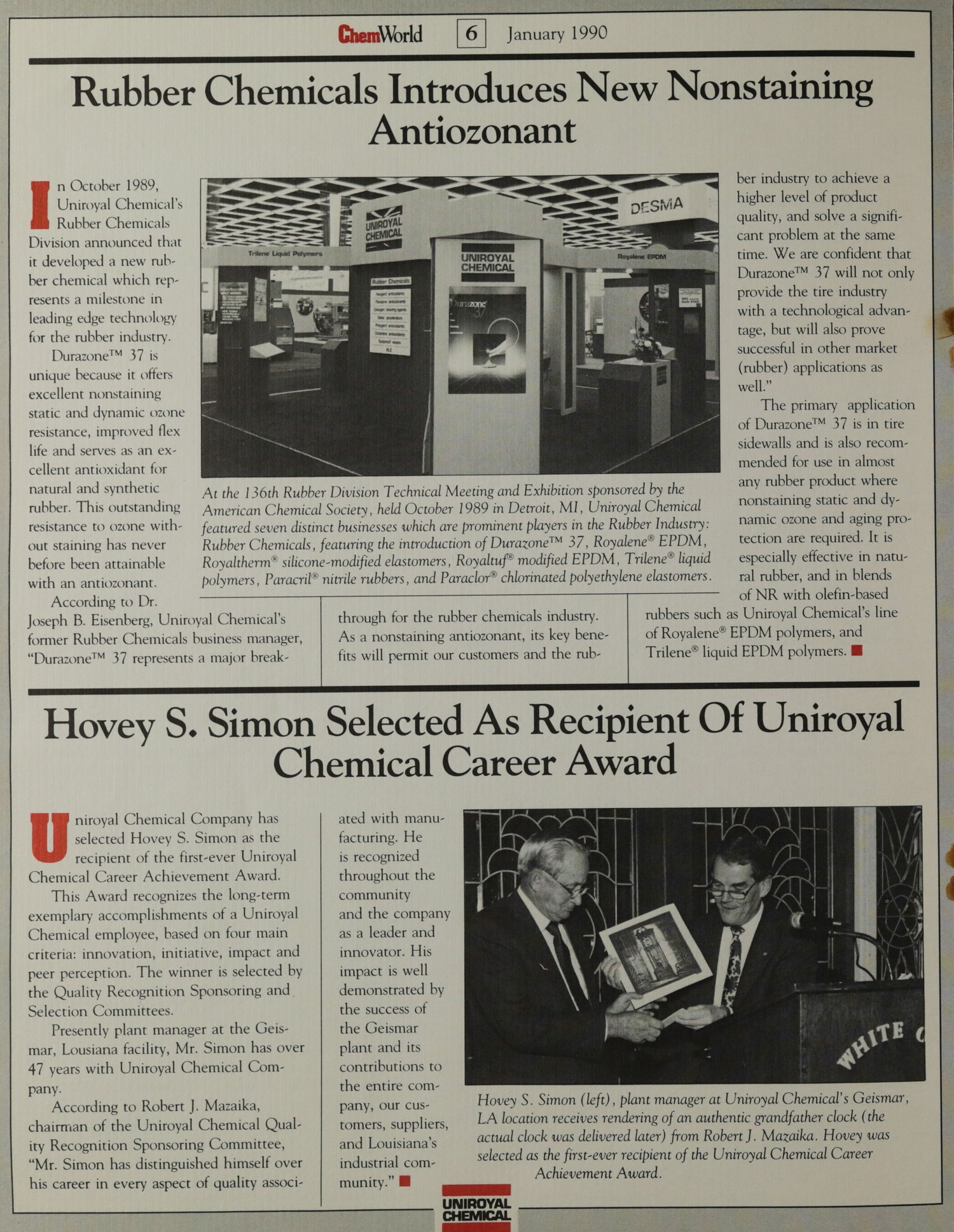

THE EMPLOYEES OF UNIROYAL CHEMICAL HAVE REASON TO CELEBRATE.

The completed management buyout of Uniroyal Chemical from Avery, Inc. was supported by two strategic subsidiaries: the “Corporate Ad” (on right) appeared in major business and financial publications nationwide as well as in various industry publications, and is recognized for quality products and services on an international level. In 1988, 65 percent of sales were from products with number one or number two market positions.

In the Crop Protection Division, Gustafson, Inc. (a wholly-owned subsidiary which sells agricultural chemicals to the seed treatment marketplace) is recognized as the technological leader and maintains a dominant market share of the North American commercial market.

In the Chemicals and Polymers Division, Uniroyal Chemical was the first company to enter the rubber chemicals business and is currently the second largest supplier of rubber chemicals in the world with over 100 different products. The Specialties Division is marked by success and innovation. Research and Development teams are currently developing new products which are environmentally sound and have low to zero toxicity. New products can potentially add significantly to the company’s future growth.

On the international front, the company began joint ventures in Korea, India and Thailand, and has been discussing the licensing of its technologies in China and the Soviet Union. This further enhances the company’s ability to do business in 120 countries and increases its manufacturing capabilities on a global level.

For the future, the company is committing more funds than ever to both research and development and to manufacturing facilities to ensure that the growth of Uniroyal Chemical continues into the next century.

The increases in R&D and in the plants will mean more jobs and more opportunities for advancement.

And, the new corporate structure means greater independence and flexibility to meet and overcome any business challenges.

The company’s success and growth, however, is dependent on the most important element in the equation – people. According to Robert Maziarka, “every worker at every level is a valuable participant in the growth and ultimate success of the company, both financially and from a product standpoint. This is the key to our future position as a leader in worldwide specialty chemicals.”

—

## Page 002

Here is the text extracted from the document image:

CbemWorld 2 January 1990

Quality Partnerships Central Theme At 1989 Uniroyal Chemical Quality Symposium

T he presentation and speakers at the 1989 Quality Symposium held in Lakeville, CT in October concentrated on the central theme of quality partnerships that are formed by and within Uniroyal Chemical Company. Raw materials suppliers representing five separate companies presented their individual quality partnership programs with emphasis ranging from total quality management to their version of Adopt-A-Customer. Two of Uniroyal Chemical’s customers also made presentations to the group of quality managers.

The structure for improvement and change necessary in today’s markets rests on the involvement of Uniroyal Chemical employees in the improvement process.

managers who reviewed the company’s quality philosophy and requirements of a supplier. According to Keith Baggett, Uniroyal Chemical’s director of Quality Assurance, “the close partnerships with customers and suppliers provide us with the information necessary to focus on the correct steps that ultimately lead to continual improvement in quality and continued growth.” Additionally, Uniroyal Chemical customers requested the company’s partnership with them in the following areas, which were also covered at the symposium: Electronic Data Interchange (EDI); European Standards Accreditation (ISO 9000); and customer certification programs.

The structure for improvement and change necessary in today’s markets rests on the involvement of Uniroyal Chemical employees in the improvement process. Updates on the involvement of the people in their plants included: Adopt-A-Customer programs, improvement in maintenance with statistical analysis of equipment vibration, excellence modeling, raw material control and steam quality control.

Other Quality Managers provided case histories of success through teamwork achieved on quality issues worldwide.

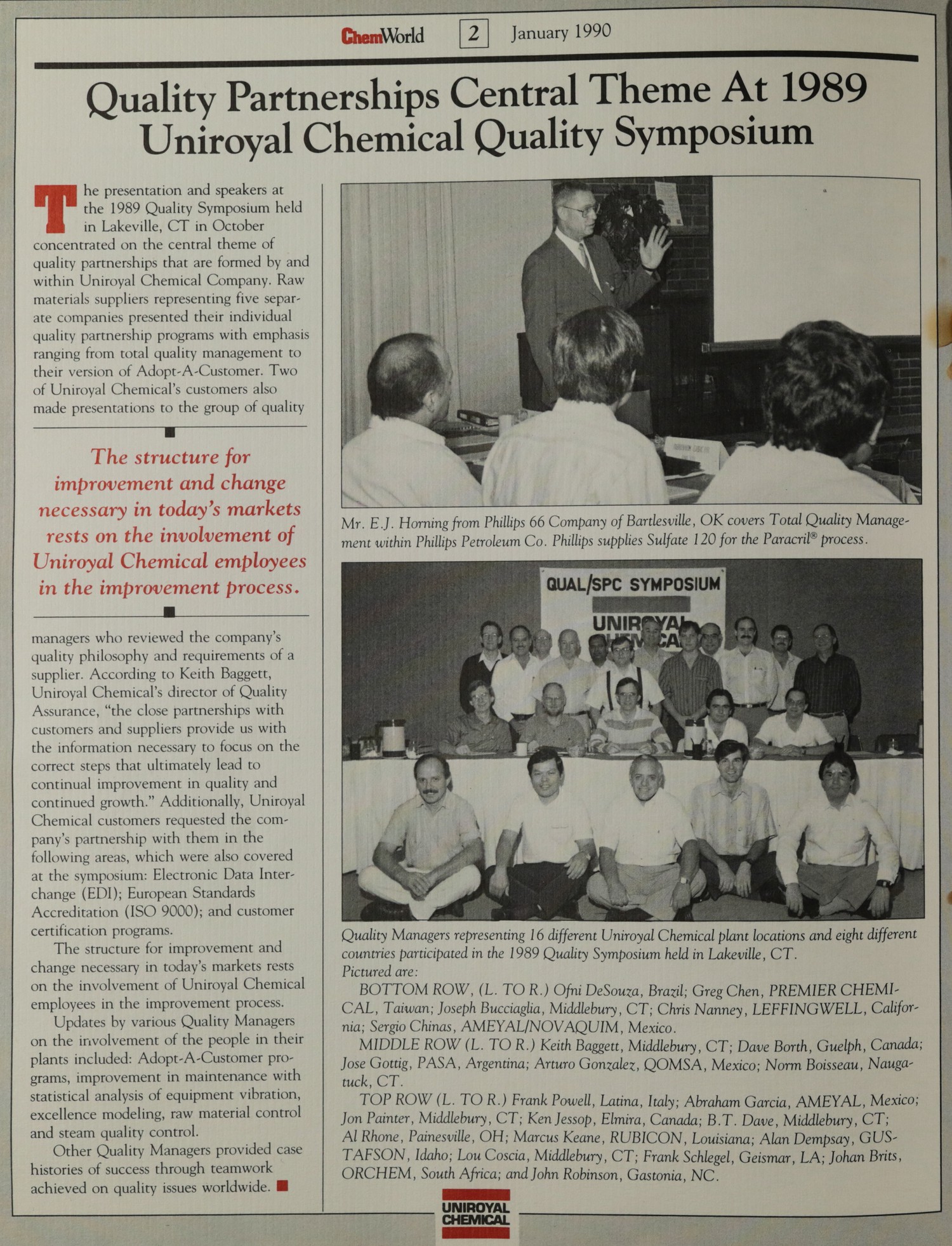

Mr. E.J. Horning from Phillips 66 Company of Bartlesville, OK covers Total Quality Management within Phillips Petroleum Co. Phillips supplies Sulfate 120 for the Paracril* process.

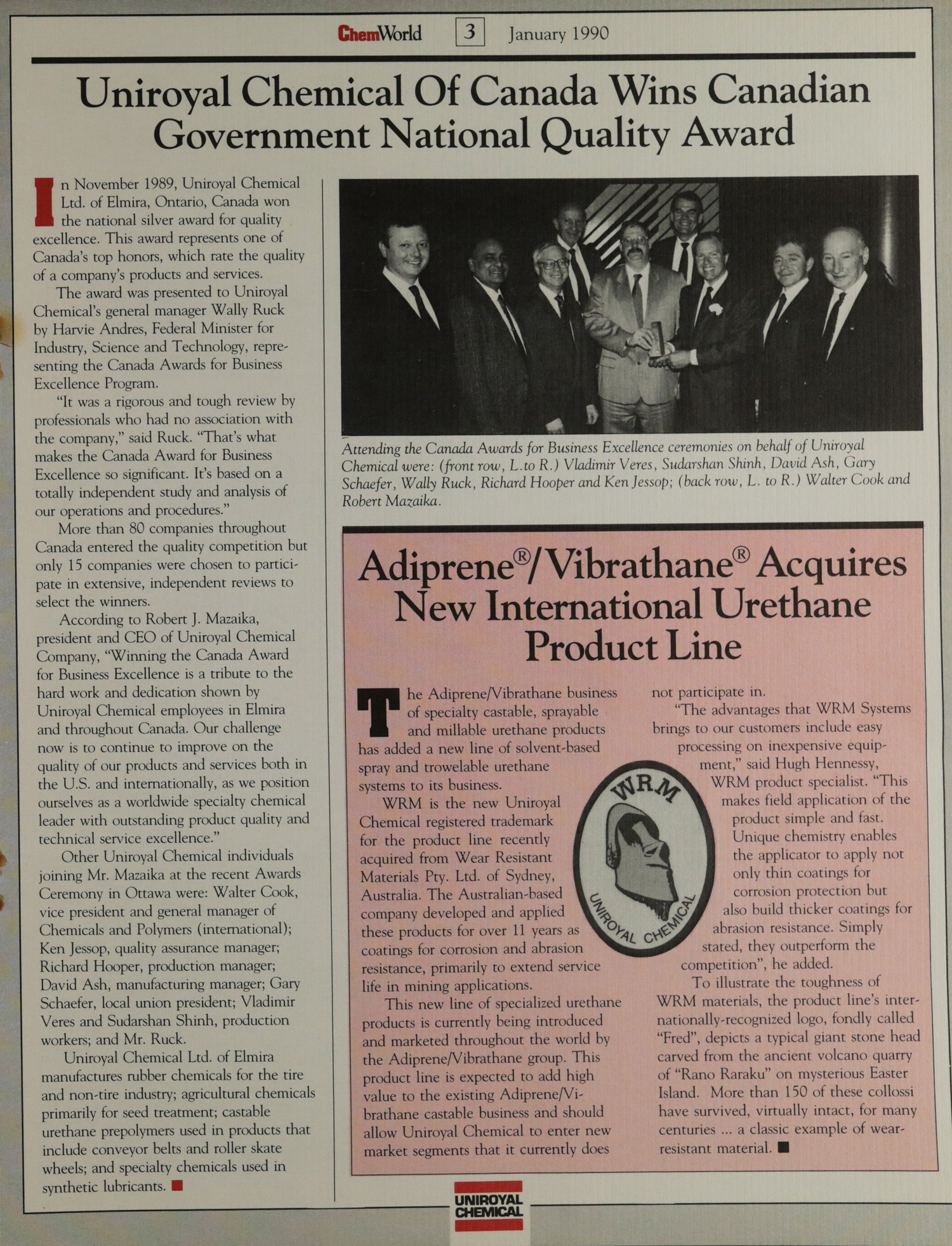

Quality Managers representing 16 different Uniroyal Chemical plant locations and eight different countries participated in the 1989 Quality Symposium held in Lakeville, CT.

BOTTOM ROW, (L. TO R.) Orli DeSouza, Brazil; Greg Chen, PREMIER CHEMICAL, Taiwan; Joseph Buccaglia, Middlebury, CT; Chris Nanney, LEFFINGWELL, California; Sergio Chims, AMEYAL/NOVAQUA, Mexico.

MIDDLE ROW (L. TO R.) Keith Baggett, Middlebury, CT; Dave Borth, Guelph, Canada; Jose Golda, PASA, Argentina; Arturo Gonzalez, QOMSA, Mexico; Norm Boisseau, Naugatuck, CT.

TOP ROW (L. TO R.) Frank Powell, Latina, Italy; Abraham Garcia, AMEYAL, Mexico; Jon Painter, Middlebury, CT; Ken Jessop, Elmira, Canada; B.T. Dave, Middlebury, CT; Al Rhone, Painesville, OH; Marcus Keane, RUBICON, Louisiana; Alan Dempsey, GUSTAFSON, Idaho; Lou Coscia, Middlebury, CT; Frank Schlegel, Geismar, LA; Johan Brits, ORCHEM, South Africa; and John Robinson, Gastonia, NC.

UNIROYAL

CHEMICAL

—

## Page 003

Uniroyal Chemical Of Canada Wins Canadian Government National Quality Award

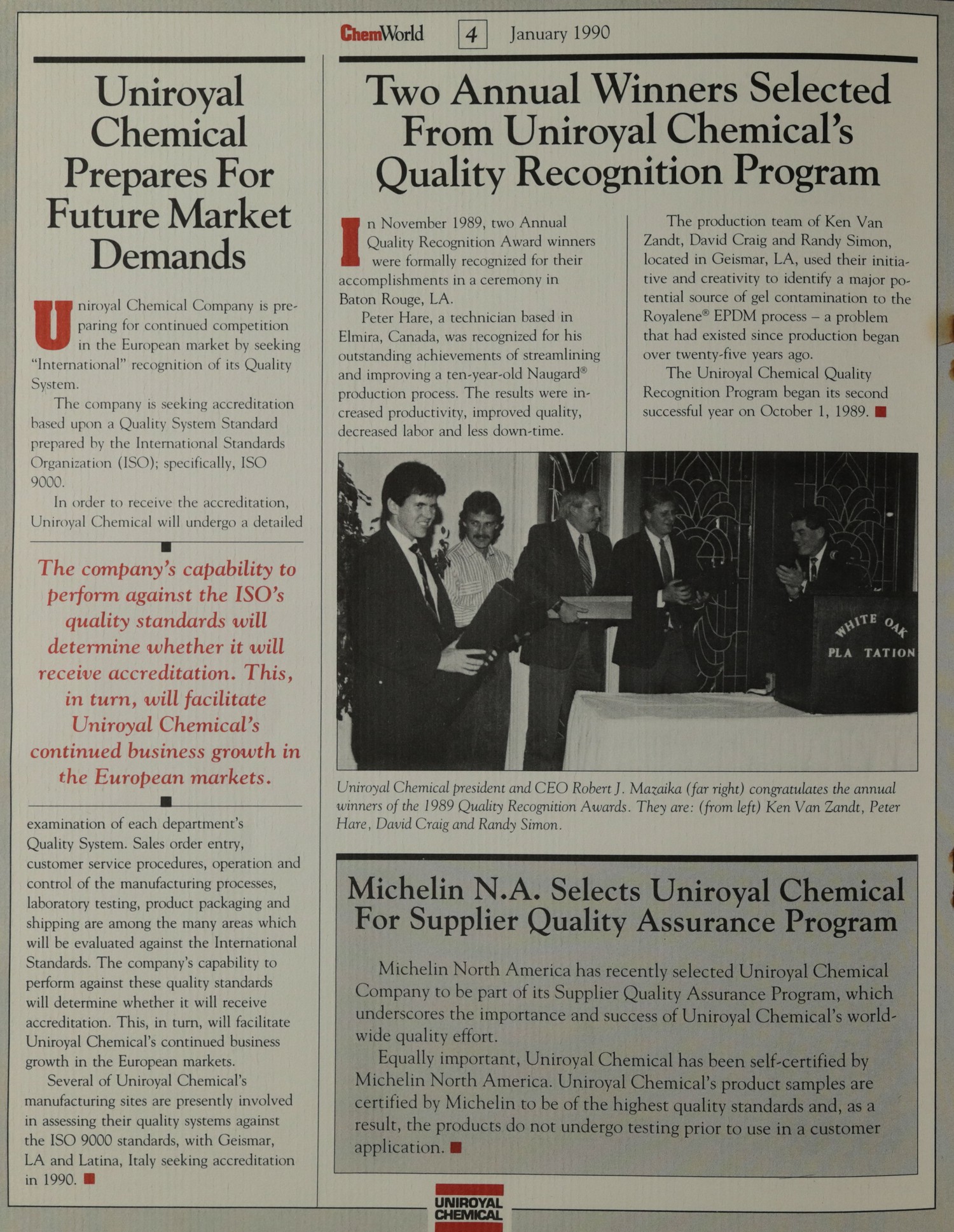

In November 1989, Uniroyal Chemical Ltd. of Elmira, Ontario, Canada won the national silver award for quality excellence. This award represents one of Canada’s top honors, which rate the quality of a company’s products and services.

The award was presented to Uniroyal Chemical’s general manager Wally Ruck by Harvie Andres, Federal Minister for Industry, Science and Technology, representing the Canada Awards for Business Excellence Program.

“It was a rigorous and tough review by professionals who had no association with the company,” said Ruck. “That’s what makes the Canada Award for Business Excellence so significant. It’s based on a totally independent study and analysis of our operations and procedures.”

More than 80 companies throughout Canada entered the quality competition but only 15 companies were chosen to participate in extensive, independent reviews to select the winners.

According to Robert J. Mazaika, president and CEO of Uniroyal Chemical Company, “Winning the Canada Award for Business Excellence is a tribute to the hard work and dedication shown by Uniroyal Chemical employees in Elmira and throughout Canada. Our challenge now is to continue to improve on the quality of our products and services both in the U.S. and internationally, as we position ourselves as a worldwide specialty chemical leader with outstanding product quality and technical service excellence.”

Other Uniroyal Chemical individuals joining Mr. Mazaika at the recent Awards Ceremony in Ottawa were: Walter Cook, vice president and general manager of Chemicals and Polymers (international); Ken Jessop, quality assurance manager; Richard Hooper, production manager; David Ash, manufacturing manager; Gary Schaefer, local union president; Vladimir Veres and Sudarshan Shnh, production workers; and Mr. Ruck.

Uniroyal Chemical Ltd. of Elmira manufactures rubber chemicals for the tire and non-tire industry; agricultural chemicals primarily for seed treatment; castable urethane prepolymers used in products that include conveyor belts and roller skate wheels; and specialty chemicals used in synthetic lubricants.

Adiprene®/Vibrathane® Acquires New International Urethane Product Line

The Adiprene/Vibrathane business of specialty castable, sprayable and millable urethane products has added a new line of solvent-based spray and towelable urethane systems to its business.

WRM is the new Uniroyal Chemical registered trademark for the product line recently acquired from Wear Resistant Materials Pty. Ltd. of Sydney, Australia. The Australian-based company developed and applied these products for over 11 years as coatings for corrosion and abrasion resistance, primarily to extend service life in mining applications.

This new line of specialized urethane products is currently being introduced and marketed throughout the world by the Adiprene/Vibrathane group. This product line is expected to add high value to the existing Adiprene/Vibrathane castable business and should allow Uniroyal Chemical to enter new market segments that it currently does not participate in.

“The advantages that WRM Systems brings to our customers include easy processing on non-responsive equipment,” said Hugh Hennessy, WRM product specialist. “This makes field application of the product simple and fast. Unique chemistry enables the applicator to apply not only thin coatings for corrosion protection but also build tough coatings for abrasion resistance. Simply stated, they outperform the competition,” he added.

To illustrate the toughness of WRM materials, the product line’s internationally-recognized logo, fondly called “Fred”, depicts a typical giant stone head carved from the ancient volcanic quarry of “Rano Raraku” on mysterious Easter Island. More than 150 of these colossal heads have survived, virtually intact, for many centuries … a classic example of wear-resistant material.

—

## Page 004

Uniroyal Chemical Prepares For Future Market Demands

Uniroyal Chemical Company is preparing for continued competition in the European market by seeking “International” recognition of its Quality System.

The company is seeking accreditation based upon a Quality System Standard prepared by the International Standards Organization (ISO); specifically, ISO 9000.

In order to receive the accreditation, Uniroyal Chemical will undergo a detailed examination of each department’s Quality System. Sales order entry, customer service procedures, operation and control of the manufacturing processes, laboratory testing, product packaging and shipping are among the many areas which will be evaluated against the International Standards. The company’s capability to perform against these quality standards will determine whether it will receive accreditation. This, in turn, will facilitate Uniroyal Chemical’s continued business growth in the European markets.

Two Annual Winners Selected From Uniroyal Chemical’s Quality Recognition Program

In November 1989, two Annual Quality Recognition Award winners were formally recognized for their accomplishments in a ceremony in Baton Rouge, LA.

Peter Hare, a technician based in Elmira, Canada, was recognized for his outstanding achievements of streamlining and improving a ten-year-old Naugard* production process. The results were increased productivity, improved quality, decreased labor and less down-time.

The production team of Ken Van Zandt, David Craig and Randy Simon, located in Geismar, LA, used their initiative and creativity to identify a major potential source of gel contamination to the Royalene* EPDM process – a problem that had existed since production began over twenty-five years ago.

The Uniroyal Chemical Quality Recognition Program began its second successful year on October 1, 1989.

Michelin N.A. Selects Uniroyal Chemical For Supplier Quality Assurance Program

Michelin North America has recently selected Uniroyal Chemical Company to be part of its Supplier Quality Assurance Program, which underscores the importance and success of Uniroyal Chemical’s world-wide quality effort.

Equally important, Uniroyal Chemical has been self-certified by Michelin North America. Uniroyal Chemical’s product samples are certified by Michelin to be of the highest quality standards and, as a result, the products do not undergo testing prior to use in a customer application.

—

## Page 005

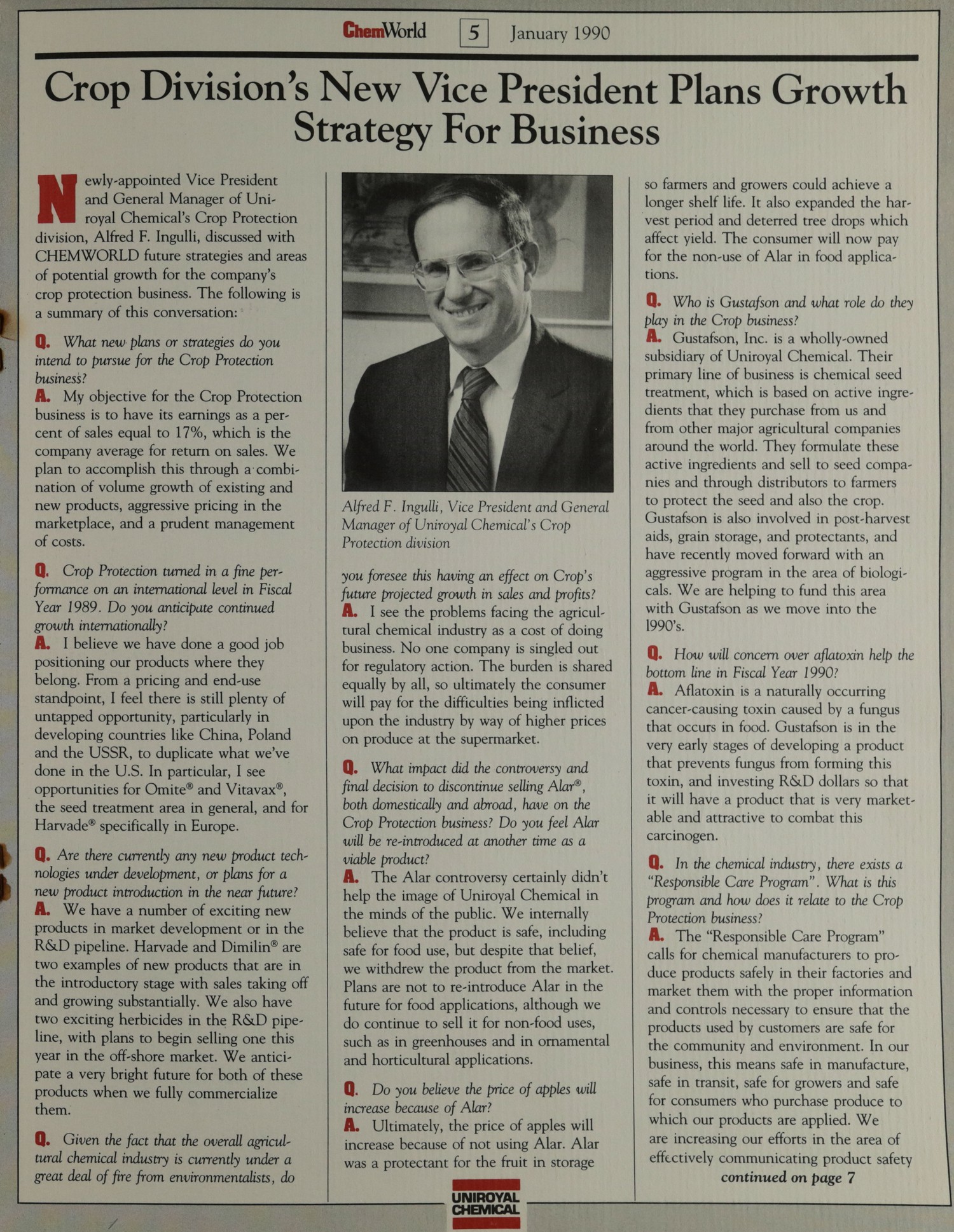

Crop Division’s New Vice President Plans Growth Strategy For Business

Newly-appointed Vice President and General Manager of Uniroyal Chemical’s Crop Protection division, Alfred F. Ingalli, discussed with CHEMWORLD future strategies and areas of potential growth for the company’s crop protection business. The following is a summary of this conversation:

Q. What new plans or strategies do you intend to pursue for the Crop Protection business?

A. My objective for the Crop Protection business is to have its earnings as a percent of sales equal to 17%, which is the company average for return on sales. We plan to accomplish this through a combination of volume growth of existing and new products, aggressive pricing in the marketplace, and a prudent management of costs.

Q. Crop Protection turned in a fine performance on an international level in Fiscal Year 1989. Do you anticipate continued growth internationally?

A. I believe we have done a good job positioning our products where they belong. From a pricing and end-use standpoint, I feel there is still plenty of untapped opportunity, particularly in developing countries like China, Poland and the USSR, to duplicate what we’ve done in the U.S. In particular, I see opportunities for Onitek and Viatavax, the seed treatment area in general, and for Harvelex specifically in Europe.

Q. Are there currently any new product technologies under development, or plans for a new product introduction in the near future?

A. We have a number of exciting new products in market development or in the R&D pipeline. Harvelex and Dimlin* are two examples of new products that are in the introductory stage with sales taking off and growing substantially. We also have two exciting herbicides in the R&D pipeline, with plans to begin selling one this year in the off-shore market. We anticipate a very bright future for both of these products when we fully commercialize them.

Q. Given the fact that the overall agricultural chemical industry is currently under a great deal of fire from environmentalists, do you foresee this having an effect on Crop’s future projected growth in sales and profits?

A. I see the problems facing the agricultural chemical industry as a cost of doing business. No one company is singled out for regulatory action. The burden is shared equally by all, so ultimately the consumer will pay for the difficulties being inflicted upon the industry by way of higher prices on produce at the supermarket.

Q. What impact did the controversy and final decision to discontinue selling Alar, both domestically and abroad, have on Crop Protection business? Do you feel Alar will be re-introduced at another time as a viable product?

A. The Alar controversy certainly didn’t help the image of Uniroyal Chemical in the minds of the public. We internally believe that the product is safe, including safe for food use, but despite that belief, we withdrew the product from the market. Plans are not to re-introduce Alar in the future for food applications, although we do continue to sell it for non-food uses, such as in greenhouses and in ornamental and horticultural applications.

Q. Do you believe the price of apples will increase because of Alar?

A. Ultimately, the price of apples will increase because of not using Alar. Alar was a protectant for the fruit in storage so farmers and growers could achieve a longer shelf life. It also expanded the harvest period and deterred tree drops which affect yield. The consumer will now pay for the non-use of Alar in food applications.

Q. Who is Gustafson and what role do they play in the Crop business?

A. Gustafson, Inc. is a wholly-owned subsidiary of Uniroyal Chemical. Their primary line of business is chemical seed treatment, which is based on active ingredients that they purchase from us and from other major agricultural companies around the world. They formulate these active ingredients and sell to seed companies and through distributors to farmers to protect the seed and also the crop. Gustafson is also involved in post-harvest aids, grain storage, and protectants, and have recently moved forward with an aggressive program in the area of biologicals. We are helping to fund this area with Gustafson as we move into the 1990’s.

Q. How will concern over aflatoxin help the bottom line in Fiscal Year 1990?

A. Aflatoxin is a naturally occurring cancer-causing toxin caused by a fungus that occurs in food. Gustafson is in the very early stages of developing a product that prevents fungus from forming this toxin, and investing R&D dollars so that it will have a product that is very marketable and attractive to combat this carcinogen.

Q. In the chemical industry, there exists a “Responsible Care Program”. What is this program and how does it relate to the Crop Protection business?

A. The “Responsible Care Program” calls for chemical manufacturers to produce products safely in their factories and market them with the proper information and controls necessary to ensure that the products used by consumers are safe for the community and environment. In our business, this means safe in manufacture, safe in transit, safe for growers and safe for consumers who purchase produce to which our products are applied. We are increasing our efforts in the area of effectively communicating product safety.

—

## Page 006

Here is the text extracted from the document image:

Rubber Chemicals Introduces New Nonstaining Antiozonant

In October 1989, Uniroyal Chemical’s Rubber Chemicals Division announced that it developed a new rubber chemical which represents a milestone in leading edge technology for the rubber industry. Durazone™ 37 is unique because it offers excellent nonstaining static and dynamic ozone resistance, improved flex life and serves as an excellent antioxidant for natural and synthetic rubber. This outstanding resistance to ozone with our staining has never before been attainable with an antioxidant.

According to Dr. Joseph B. Eisenberg, Uniroyal Chemical’s former Rubber Chemicals business manager, “Durazone™ 37 represents a major breakthrough for the rubber chemicals industry to achieve a higher level of product quality, and solve a significant problem at the same time. We are confident that Durazone™ 37 will not only provide the tire industry with a technological advantage, but will also prove successful in other market (rubber) applications as well.”

The primary application of Durazone™ 37 is in tire sidewalls and is also recommended for use in almost any rubber product where nonstaining static and dynamic ozone and aging protection are required. It is especially effective in natural rubber, and in blends of NR with olefin-based rubbers such as Uniroyal Chemical’s line of Royalene® EPDM polymers, and Trilene® liquid EPDM polymers.

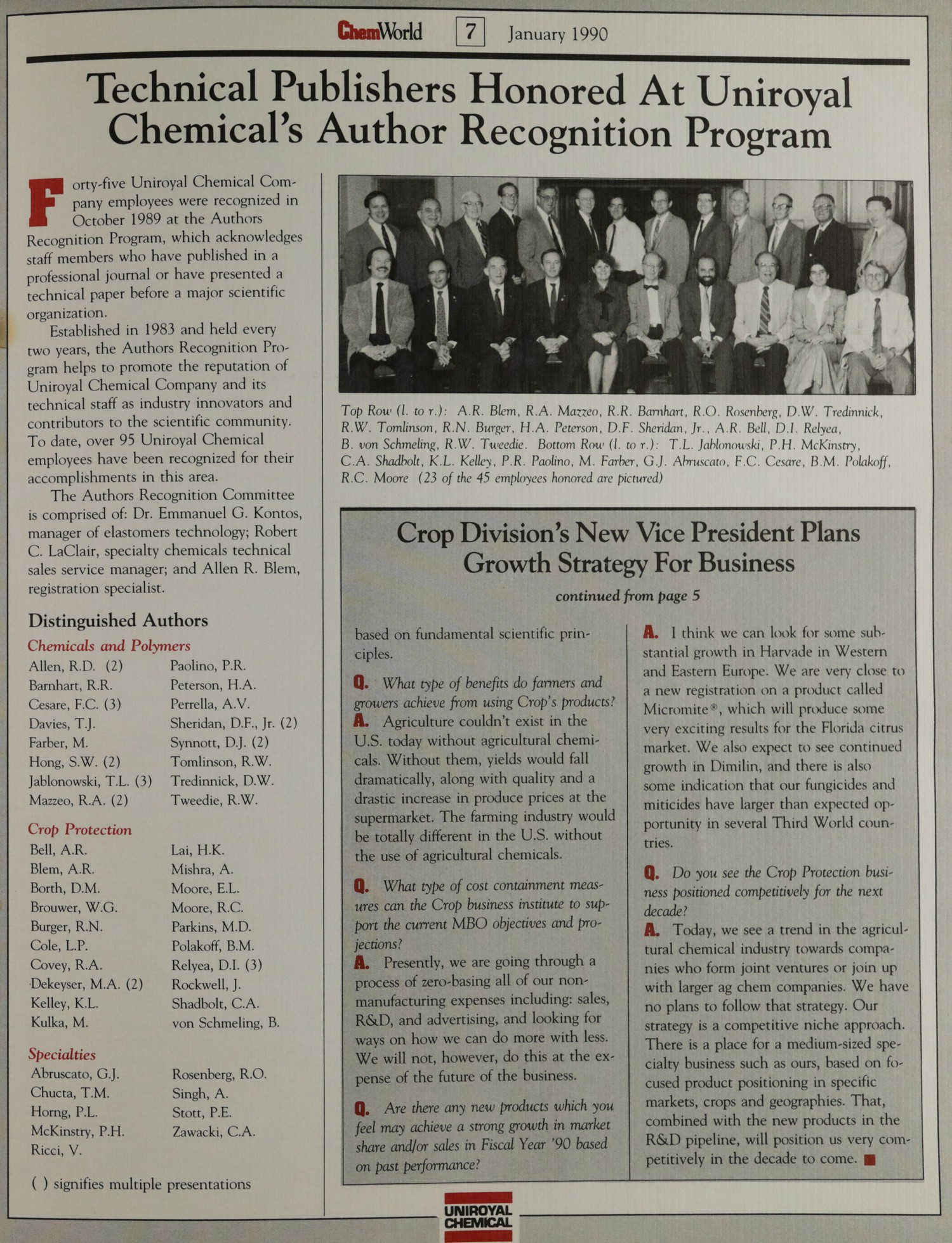

At the 136th Rubber Division Technical Meeting and Exhibition sponsored by the American Chemical Society, held October 1989 in Detroit, MI, Uniroyal Chemical featured several distinct businesses which are prominent in the Rubber Industry: Rubber Chemicals, featuring the introduction of Durazone™ 37, Royalene® EPDM, Royaltuf™ silicone-modified elastomers, and Trilene® liquid polymers, Duracast™ milled rubber, and Duraplus™ chlorinated polyethylene customers.

Hovey S. Simon Selected As Recipient Of Uniroyal Chemical Career Award

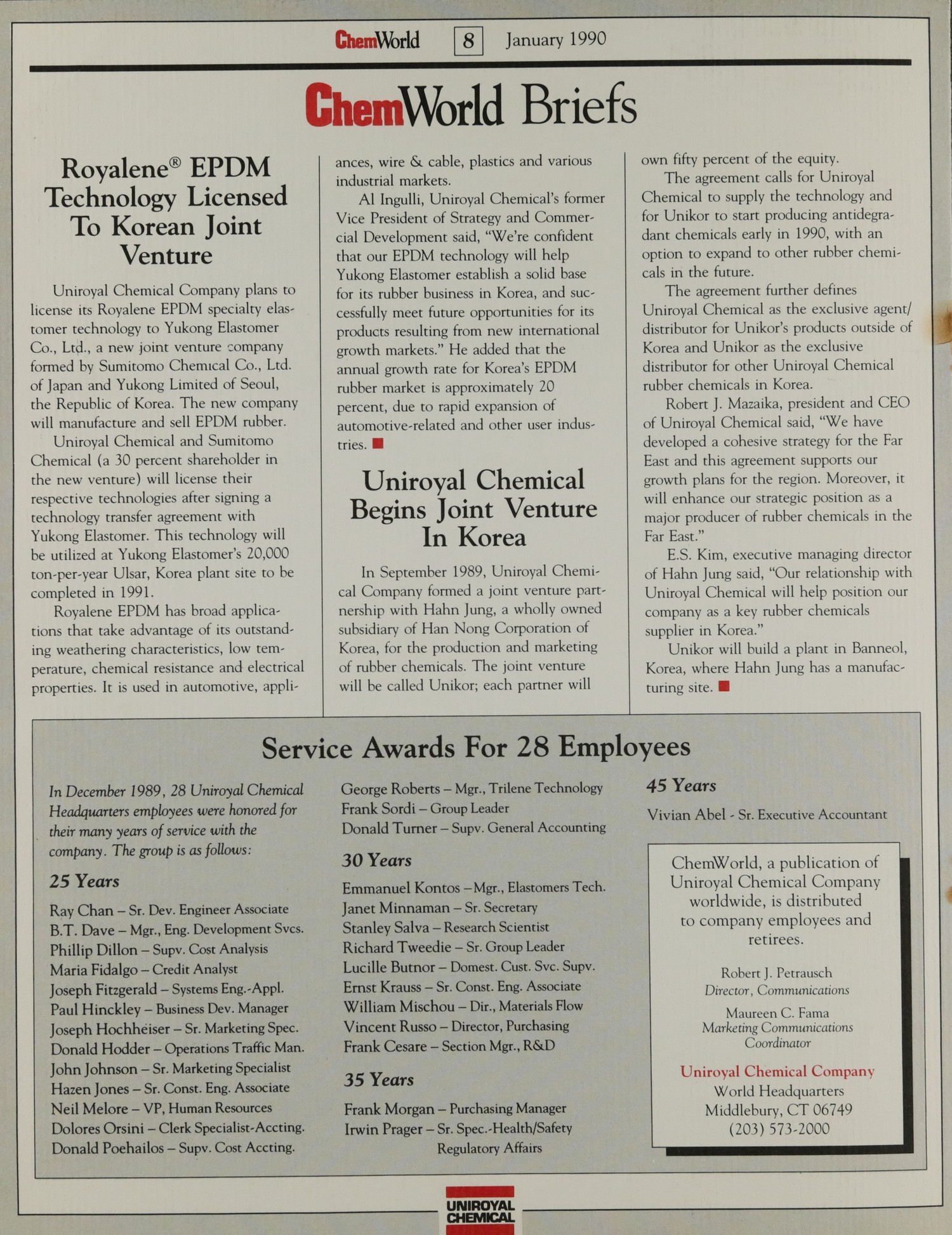

Uniroyal Chemical Company has selected Hovey S. Simon as the recipient of the first-ever Uniroyal Chemical Career Achievement Award. This Award recognizes the long-term exemplary accomplishments of a Uniroyal Chemical employee, based on four main criteria: innovation, initiative, impact and peer perception. The winner is selected by the Quality Recognition Sponsoring and Selection Committees.

Presently plant manager at the Geismar, Lousiana facility, Mr. Simon has over 47 years with Uniroyal Chemical Company. According to Robert J. Mazaika, chairman of the Uniroyal Chemical Quality Recognition Sponsoring Committee, “Mr. Simon has distinguished himself over his career in every aspect of quality associated with manufacturing. He is recognized throughout the community and the company as a leader and innovator. His impact is well demonstrated by the success of the Geismar plant and its contributions to the entire company, our customers, suppliers, and Louisiana’s industrial community.”

Hovey S. Simon (left), plant manager at Uniroyal Chemical’s Geismar, LA location receives rendering of an authentic grandfather clock (the actual clock was delivered later) from Robert J. Mazaika. Hovey was selected as the first-ever recipient of the Uniroyal Chemical Career Achievement Award.

—

## Page 007

Technical Publishers Honored At Uniroyal Chemical’s Author Recognition Program

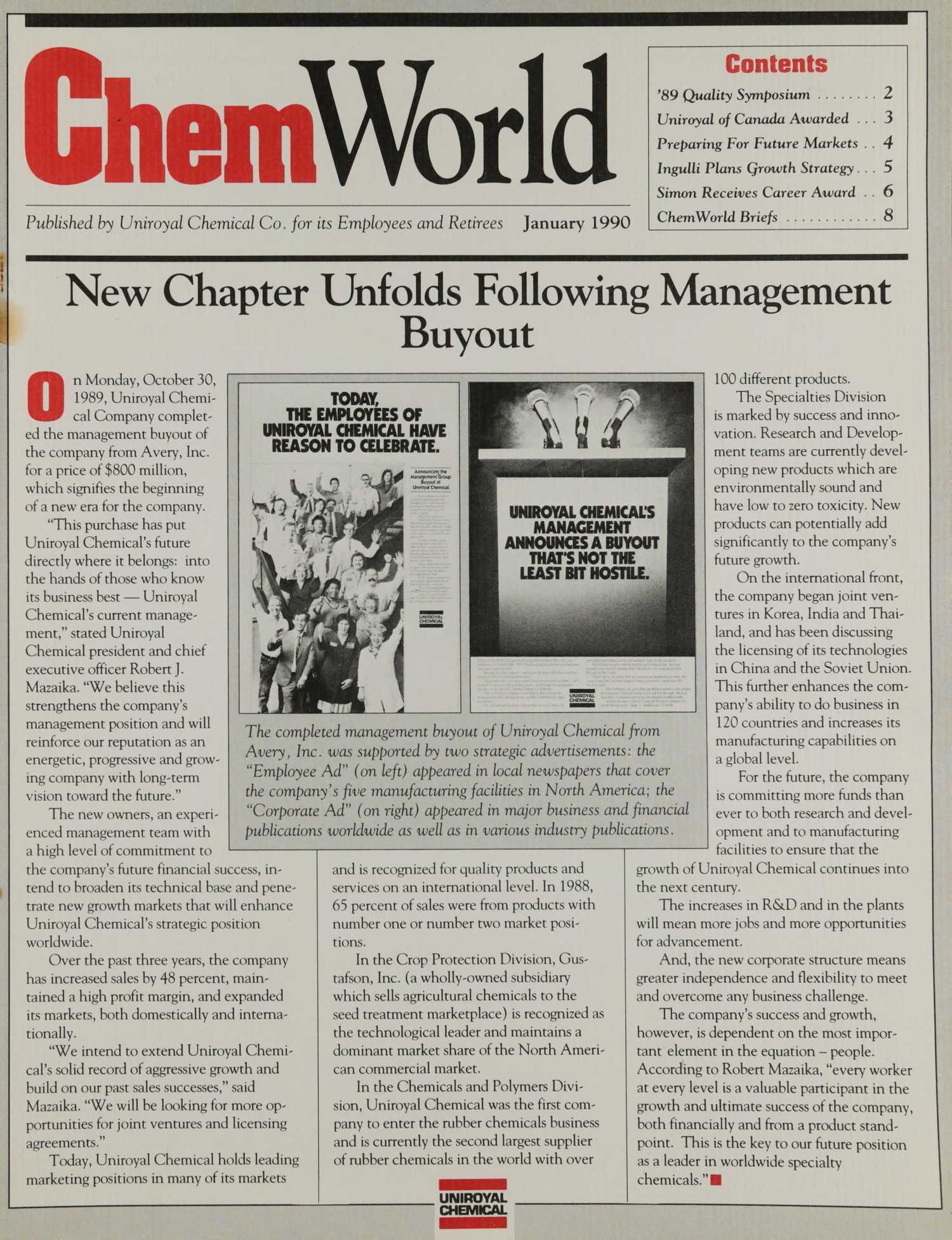

Forty-five Uniroyal Chemical Company employees were recognized in October 1989 at the Authors Recognition Program, which acknowledges staff members who have published in a professional journal or have presented a technical paper before a major scientific organization.

Established in 1983 and held every two years, the Authors Recognition Program helps to promote the reputation of Uniroyal Chemical Company and its technical staff as industry innovators and contributors to the scientific community. To date, over 95 Uniroyal Chemical employees have been recognized for their accomplishments in this area.

The Authors Recognition Committee is comprised of: Dr. Emmanuel G. Kontos, manager of elastomers technology; Robert C. LaClair, specialty chemicals technical sales service manager; and Allen R. Blem, registration specialist.

Distinguished Authors

Chemicals and Polymers

Allen, R.D. (2) Paulino, P.R.

Barnhart, R.R. Peterson, H.A.

Cesare, F.C. (3) Perella, A.V.

Davis, T.L. Sheridan, D.J. (2)

Farber, M. Synnott, D.J. (2)

Hong, S.W. (2) Tomlinson, R.W.

Jablonowski, T.L. (3) Trednick, D.W.

Mazzo, R.A. (2) Tweedie, R.W.

Crop Protection

Bell, A.R. Lai, H.K.

Blem, A.R. Mishra, A.

Borth, D.M. Moore, E.L.

Brouwer, W.G. Moore, R.C.

Burger, R.N. Parkins, M.D.

Cole, L.P. Polakoff, B.M.

Covey, R.A. Relyea, D.I. (3)

Dekeyser, M.A. (2) Rockwell, J.

Kelley, K.L. Shailesh, C.A.

Kulka, M. von Schenling, B.

Specialties

Abruscato, G.J. Rosenberg, R.O.

Chucta, T.M. Singh, A.

Horng, P.L. Stott, P.E.

McKinstry, P.H. Zawacki, C.A.

Ricci, V.

Crop Division’s New Vice President Plans Growth Strategy For Business

[Article continued from page 5]

A. I think we can look for some substantial growth in Havadie in Western and Eastern Europe. We are very close to a new registration on a product called Meroune*, which will produce some very exciting results for the Florida citrus market. We also expect to see continued growth in Dimlin, and there is also some indication that our fungicides and miticides have larger than expected opportunity in several Third World countries.

Q. Do you see the Crop Protection business positioned competitively for the next decade?

A. Today, we see a trend in the agricultural chemical industry towards companies who form joint ventures or join up with larger ag chem companies. We have no plans to follow that strategy. Our strategy is a competitive niche approach. There is a place for a medium-sized specialty business such as ours, based on focused product positioning in specific markets, crops and geographies. That, combined with the new products in the R&D pipeline, will position us very competitively in the decade to come.

—

## Page 008

ChamWorld 8 January 1990

ChamWorld Briefs

Royalene® EPDM

Technology Licensed

To Korean Joint

Venture

Uniroyal Chemical Company plans to

license its Royalene EPDM specialty customer technology to Yukong Elastomer

Co., Ltd., a new joint venture company

formed by Sumitomo Chemical Co., Ltd.

of Japan and Yukong Limited of Seoul,

the Republic of Korea. The new company

will manufacture and sell EPDM rubber.

Uniroyal Chemical and Sumitomo

Chemical (a 30 percent shareholder in

the new venture) will license their

respective technologies after signing a

technology transfer agreement with

Yukong Elastomer. This technology will

be utilized at Yukong Elastomer’s 20,000

ton-per-year Ulsan, Korea plant site to be

completed in 1991.

Royalene EPDM has broad applications that take advantage of its outstanding weathering characteristics, low temperature, chemical resistance and electrical

properties. It is used in automotive, appliances, wire & cable, plastics and various

industrial markets.

Al Ingulli, Uniroyal Chemical’s former

Vice President of Strategy and Commercial Development said, “We’re confident

that our EPDM technology will help

Yukong Elastomer establish a solid base

for its rubber business in Korea, and successfully meet future opportunities for its

products resulting from new international

growth markets.” He added that the

annual growth rate for Korea’s EPDM

rubber market is approximately 20

percent, due to rapid expansion of

automotive-related and other user industries.

Uniroyal Chemical

Begins Joint Venture

In Korea

In September 1989, Uniroyal Chemical Company formed a joint venture partnership with Hahn Jung, a wholly owned

subsidiary of Han Nong Corporation of

Korea, for the production and marketing

of rubber chemicals. The joint venture

will be called Unikor, and the partner will

own fifty percent of the equity.

The agreement calls for Uniroyal

Chemical to supply the technology and

for Unikor to start producing antidegradant chemicals early in 1990, with an

option to expand to other rubber chemicals in the future.

The agreement further defines

Uniroyal Chemical as the exclusive agent/

distributor for Unikor’s products outside of

Korea and Unikor as the exclusive

distributor for other Uniroyal Chemical

rubber chemicals in Korea.

Robert J. Mazaika, president and CEO

of Uniroyal Chemical said, “We have

developed a cohesive strategy for the Far

East and this agreement supports our

growth plans for the region. Moreover, it

will enhance our strategic position as a

major producer of rubber chemicals in the

Far East.”

E.S. Kim, executive managing director

of Hahn Jung said, “Our relationship with

Uniroyal Chemical will help position our

company as a key rubber chemicals

supplier in Korea.”

Unikor will build a plant in Banreol,

Korea, where Hahn Jung has a manufacturing site.

Service Awards For 28 Employees

In December 1989, 28 Uniroyal Chemical

Headquarters employees were honored for

their many years of service with the

company. The group is as follows:

George Roberts – Mgr., Trilene Technology

Frank Sordi – Group Leader

Donald Turner – Supv. General Accounting

25 Years

30 Years

Ray Chan – Sr. Dev. Engineer Associate

B.T. Dave – Mgr., Eng. Development Svcs.

Phillip Dillon – Supv. Cost Analyst

Maria Fidalgo – Credit Analyst

Joseph Fitzgerald – Systems Eng.-Appl.

Paul Hinckley – Business Dev. Manager

Joseph Hochheimer – Sr. Marketing Spec.

Donald Hodder – Operations Traffic Man.

John Johnson – Sr. Marketing Specialist

Hazen Jones – Sr. Const. Eng. Associate

Neil Melore – VP, Human Resources

Dolores Orsini – Clerk Specialist-Acting

Donald Pechallos – Supv. Cost Acctng.

Emmanuel Kontos – Mgr., Elastomers Tech.

Janet Minnaman – Sr. Secretary

Stanley Salva – Research Scientist

Richard Tweedie – Sr. Group Leader

Lucille Burnor – Domest. Cust. Svc. Supv.

Ernst Krauss – Sr. Const. Eng. Associate

William Mischou – Dir., Materials Flow

Vincent Russo – Director, Purchasing

Frank Cesare – Section Mgr., R&D

45 Years

Vivian Abel – Sr. Executive Accountant

35 Years

Frank Morgan – Purchasing Manager

Irwin Prager – Sr. Spec.-Health/Safety

Regulatory Affairs

ChamWorld, a publication of

Uniroyal Chemical Company

worldwide, is distributed

to company employees and

retirees.

Robert J. Petrausch

Director, Communications

Maureen C. Fama

Marketing Communications

Coordinator

Uniroyal Chemical Company

World Headquarters

Middlebury, CT 06749

(203) 573-2000

—

Note 30th year anniversaries: William Mischou – Dir., Materials Flow

Vincent Russo – Director, Purchasing

Also — Ernst Krauss – Sr. Const. Eng. Associate??? Was he in CT?!